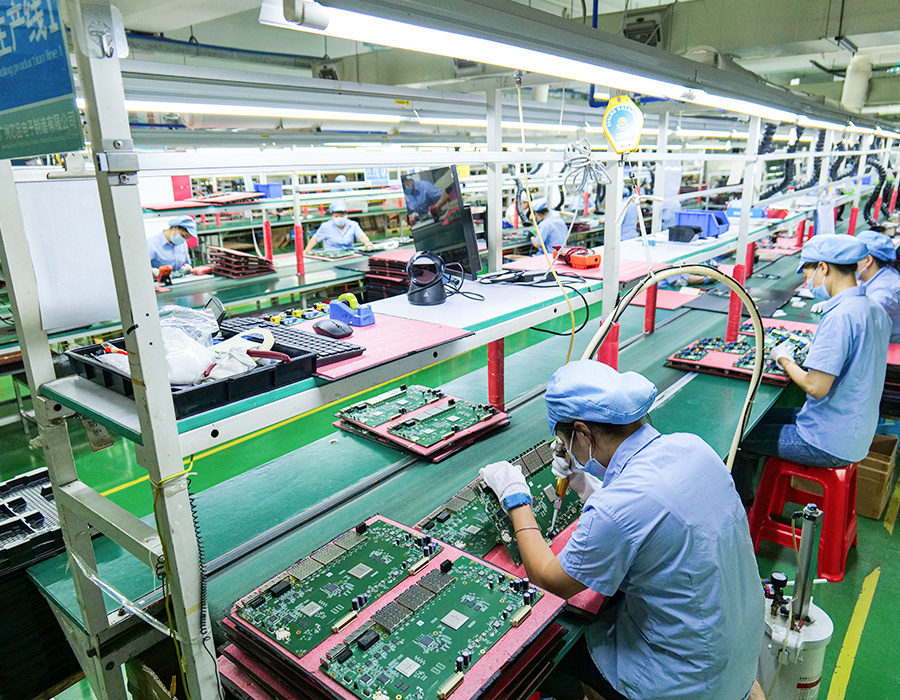

Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

SMT Surface Mount Technology Processing Introduction

The volume of SMT surface mount components is only about 10% of that of traditional packaged components, and the weight is also only 10% of that of traditional plug-in components. SMT technology can usually reduce the volume of electronic products by 40%~60%, reduce the weight by 60%~80%, and significantly reduce the area and weight.

I. Why is SMT surface mount technology so popular, and what are its characteristics?

1. Small electronic product size and high assembly density

The volume of SMT surface mount components is only about 10% of that of traditional packaged components, and the weight is also only 10% of that of traditional through-hole components. SMT technology can usually reduce the volume of electronic products by 40%~60%, reduce the weight by 60%~80%, and significantly reduce the area and weight. The grid of SMT surface mount processing assembly components has developed from 1.27mm to the current 0.63mm grid, and some have reached 0.5mm grid. Using through-hole mounting technology can improve assembly density.

2. High reliability and strong vibration resistance

SMT surface mount technology uses chip components, which have high reliability, small size, light weight, strong vibration resistance, automated production, high installation reliability, and a low defective solder joint rate, generally less than ten parts per million. This is an order of magnitude lower than the wave soldering technology for through-hole components, ensuring a low defect rate in the solder joints of electronic products or components. Currently, nearly 90% of electronic products use SMT technology.

3. Good high-frequency characteristics and reliable performance

Because the chip components are firmly mounted, the components are usually leadless or short-lead, which reduces the influence of parasitic inductance and parasitic capacitance, improves the high-frequency characteristics of the circuit, and reduces electromagnetic and radio frequency interference. The maximum frequency of circuits designed using SMC and SMD can reach 3GHz, while chip components are only 500MHz, which can shorten the transmission delay time. It can be used in circuits with a clock frequency of 16MHz or higher. If MCM technology is used, the high-end clock frequency of computer workstations can reach 100MHz, and the additional power consumption caused by parasitic reactance can be reduced by 2-3 times.

4. Improve productivity and achieve automated production

Currently, to achieve fully automated through-hole mounting of printed circuit boards, it is necessary to increase the original printed circuit board area by 40% so that the automatic insertion heads can insert the components; otherwise, there will not be enough space, and the parts will be damaged. The automatic placement machine (SM421/SM411) uses vacuum nozzles to pick and place components. The vacuum nozzle is smaller than the component shape, which actually improves the installation density. In fact, small components and fine-pitch QFP components are all produced by automatic placement machines to achieve fully automated production.

5. Reduce costs and expenses

(1) Reduce the printed circuit board usage area; the area is 1/12 of that of through-hole technology. If CSP mounting is used, the area will be further reduced; (2) Reduce the number of holes drilled in the printed circuit board, saving rework costs; (3) Due to the improvement in frequency characteristics, circuit debugging costs are reduced; (4) Due to the small size and light weight of chip components, packaging, transportation, and storage costs are reduced;

SMT surface mount technology can save materials, energy, equipment, manpower, and time, and costs can be reduced by as much as 30% to 50%.

II. How is desoldering done in an SMT surface mount processing plant?

For surface mount components with a larger number of pins and wider spacing, a similar method is used. First, tin plating is performed on the pads, then the component is held with tweezers, one leg is soldered on the left side, and then the other leg is soldered with solder wire. It is usually better to use a hot air gun to remove these components. On the one hand, the hand-held hot air gun melts the solder, and on the other hand, when the solder melts, a tool such as tweezers is used to remove the component.

For components with high pin density, the soldering process is similar, that is, one leg is soldered first, and then the remaining legs are soldered with solder wire. With a large number of densely packed pins, the alignment of the pins and pads is crucial. Usually, a small amount of solder is plated on the pads at the corners, and the component is aligned with the pads using tweezers or hands. The edges of the pins are aligned. These components are pressed slightly onto the printed circuit board, and the corresponding pins on the pads are soldered with a soldering iron.

Surface mount red glue is a chemical compound, the main components of which are polymer materials, fillers, curing agents, and other auxiliaries. Surface mount red glue has viscosity, fluidity, temperature characteristics, and wetting characteristics. Based on these characteristics, the purpose of using red glue in production is to firmly adhere the parts to the surface of the PCB to prevent them from falling off.

For SMD components with fewer pins, such as resistors, capacitors, bipolar and triode transistors, first tin-plate one pad on the PCB, then use tweezers in the left hand to clamp the component to the mounting position and fix it on the circuit board, and use the right hand to solder the pins on the pad to the solders on the pad with a soldering iron. The tweezers in the left hand can be released, and the remaining pins can be soldered with solder wire instead. These components are also easy to remove; as long as both ends of the component are heated simultaneously with a soldering iron, they can be removed by gently lifting them after the solder melts.

Surface mount red glue is a purely consumable material and not a necessary process product. Now, with the continuous improvement of surface mount design and technology, surface mount through-hole reflow soldering and double-sided reflow soldering have been realized, and the mounting process using surface mount glue is becoming less and less common.

III. What causes insufficient solder joint gloss in SMT surface mount processing?

In surface mount soldering technology, many customers usually have requirements for the brightness of solder joints. After all, the brightness of solder joints gives us a bright feeling. However, in the SMT surface mount process, it cannot be guaranteed that the brightness of each solder joint can reach a dazzling level. So, what are the reasons for insufficient solder joint gloss in surface mount processing?

1. Oxidation of the solder powder in the solder paste.

2. The flux in the solder paste itself contains additives that have a matting effect.

3. The preheating temperature of the reflow soldering in surface mount processing is too low, and non-volatile substances remain on the surface of the solder joint.

4. There are rosin or resin residues on the surface of the solder joint after soldering. This is a phenomenon often seen in actual operations, especially when using rosin-type solder paste. Although rosin-type flux and no-clean flux can make the solder joints slightly brighter, the presence of residues often affects this effect, especially in larger solder joints or IC pins; if cleaning is performed after soldering, the solder joint gloss should improve.

5. Since there is no standard for the brightness of solder joints, if the products soldered with solder paste without silver and the products soldered with solder paste containing silver are compared, there will definitely be some difference. This requires customers to explain their solder joint requirements to the supplier when choosing solder paste.

IV. How to Avoid Solder Paste Defects in SMT Surface Mount Processing

In SMT surface mount processing, 75% to 85% of defects are caused by solder paste defects, making solder paste defect control a major headache in daily production. Control details should be considered from the initial BOM and Gerber data preparation, to component procurement channel management, solder paste storage and usage control, solder paste printing, SPI solder paste inspection, and reflow soldering.

Therefore, during SMT processing, we can strictly implement the requirements of some quality management systems to avoid or reduce the occurrence of solder paste defects. For example: In the surface mount processing of automotive electronics, if we can implement quality requirements for electrostatic control, component storage, and solder paste storage and use, we can avoid quality problems caused by electrostatic breakdown of BGAs and IC chips.

In addition, because the same batch of products in PCBA processing may have thousands or tens of thousands of pieces, and the surface mount processing cycle is relatively long, there may be dry solder paste on the stencil, or the stencil aperture and the circuit board may not be aligned, which may lead to unnecessary solder paste at the bottom of the stencil or during PCBA outsourcing processing, resulting in poor soldering.

In the automatic printing process, fix the printing cycle to a specific mode. Ensure the stencil is positioned over the pads to ensure a clean solder paste printing process. For fine-pitch stencils, damage between thin pins due to stencil cross-section bending may cause printing defects and short circuits.

In SMT turnkey projects, after printing the solder paste, the longer the operator waits after discovering a printing error, the more difficult it is to remove the solder paste. When a problem is discovered, the improperly printed boards should be immediately immersed in a cleaning solvent, as the solder paste is easier to remove before it dries.

To prevent solder paste and other contaminants from remaining on the surface of the circuit board, wipe it with a clean cloth. After immersion, use a gentle spray to wash, and it is best to use a hot air gun for drying. If using a horizontal stencil cleaner, the cleaning side should be down to allow the solder paste to fall off the board.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs