Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

PCB Board Manufacturing Process Revealed: Preliminary Steps for SMT Chip Mounting

Unveiling PCB Manufacturing: Preliminary Steps in SMT Surface Mount Technology

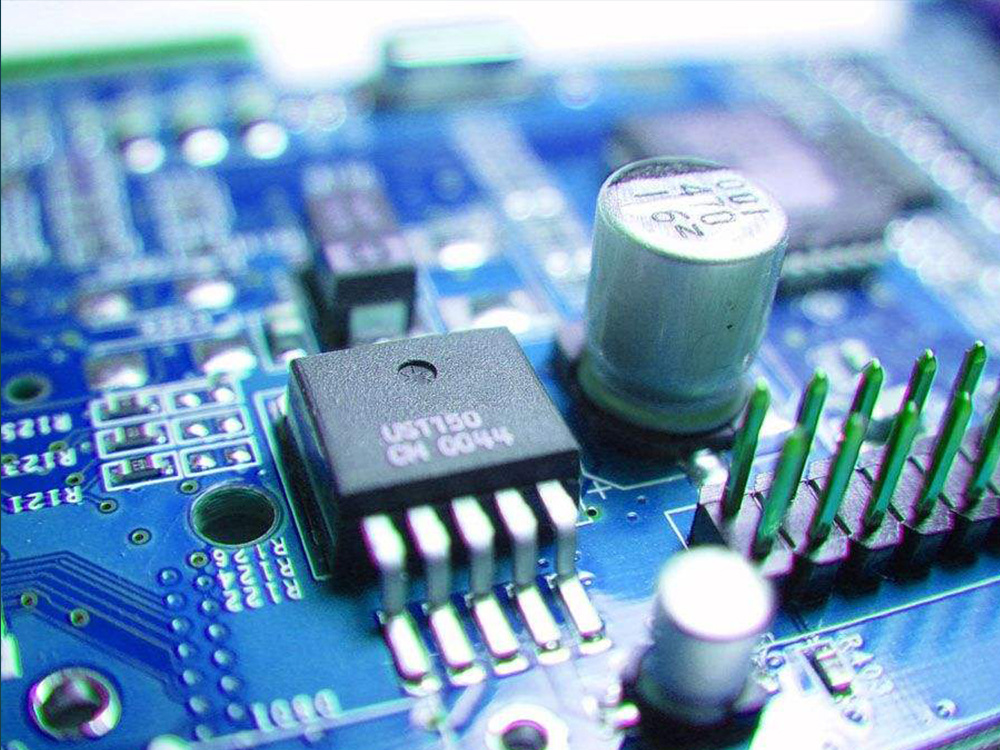

In the manufacturing of electronic products, PCBs (Printed Circuit Boards) play a crucial role. In the PCB production process, SMT (Surface Mount Technology) surface mount processing is a key step. Today, let's discuss the preliminary preparations in an SMT surface mount processing plant; these steps may seem simple, but they are the cornerstone of ensuring product quality and production efficiency.

What is SMT Surface Mount Processing?

SMT surface mount processing, as the name suggests, is a technology that attaches electronic components to the surface of a PCB through a special process. Compared to traditional through-hole components, SMT components are smaller and lighter, thus widely used in modern electronic products. Imagine, in this information explosion era, who can resist the temptation of lightweight and efficient products?

Preliminary Preparations for SMT Surface Mount Processing

Before SMT surface mount processing, PCB design and prototyping are necessary. During the design process, the circuit layout, component placement, and their interconnections must be considered. This stage is like writing a script for a movie; the quality of the script directly determines the smoothness of the subsequent filming.

Once the design is complete, PCB prototyping is needed; this step is crucial for verifying the feasibility of the design. If problems are found during prototyping, timely correction is essential. It's like a painter constantly adjusting and refining their work during the creation process, ensuring the final presentation is perfect.

Silk Screen Printing and Labeling

In SMT surface mount processing plants, silk screen printing and labeling are also important preliminary steps. Silk screen printing is mainly used to mark the position and polarity of components on the PCB for subsequent mounting operations. Imagine, without these markings, operators might be confused during mounting, leading to incorrect installation and ultimately affecting product performance.

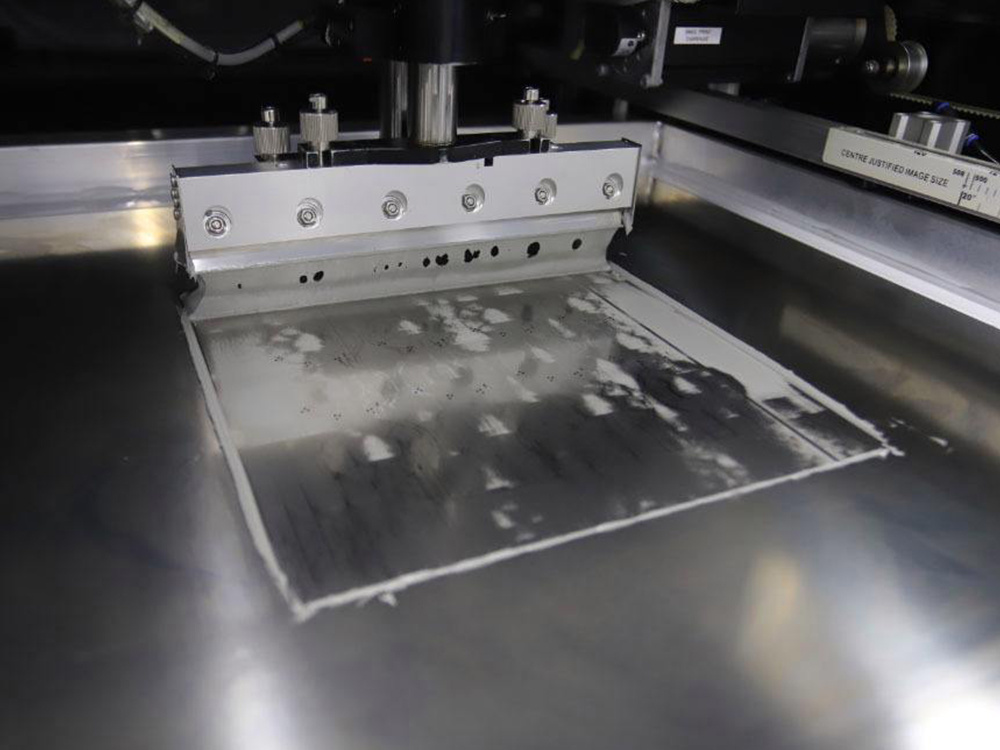

In this step, a screen printing machine is essential; it prints ink onto the PCB through a screen to create clear markings. For labeling, in addition to ensuring label clarity, the temperature and abrasion resistance of the labels must also be considered. After all, electronic products face various environmental challenges during use; these details cannot be overlooked.

The Importance of Solder Paste Printing

Next, solder paste printing is a crucial step in SMT surface mount processing. Solder paste is the key material for connecting components to the PCB; the uniformity of printing directly affects the quality of the soldering. This process is like preparing seasonings for a feast; too much or too little is not good; it must be precise.

During solder paste printing, an automatic printing machine is used to ensure that each pad is evenly covered with solder paste. This step also requires strict quality control to ensure that the solder paste thickness and position meet the standards. Imagine, if the solder paste printing is improper, the subsequent mounting process will be like walking in the desert—difficult.

The Start of the Mounting Process

After all the preparations are complete, the core process of SMT surface mount processing can finally begin. The mounting machine precisely places the components on the PCB. This process not only requires high-precision equipment but also experienced operators for monitoring. It's like a skilled chef directing various aspects in the kitchen, ensuring that each dish is perfectly seasoned.

During the mounting process, the equipment takes components from the tape according to the preset program and accurately places them on the pre-printed solder paste. The efficiency and accuracy of this step directly relate to the operation of the entire production line. It can be said that the mounting process is the "heart" of SMT surface mount processing; its health determines the success or failure of the product.

Concluding Thoughts

From the above description, we can see that SMT surface mount processing is not simply sticking components on, but a systematic and complex process. Each step requires careful design and strict control to ensure the quality and reliability of the final product. If you are looking for a professional SMT surface mount processing plant, consider learning more about their production processes and technical capabilities!

MORE BUSINESS

Component Storage and Solder Paste Printing