Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Exploring the importance of DIP plug-in processing in electronics manufacturing

Exploring the Importance of DIP Plugin Processing in Electronics Manufacturing

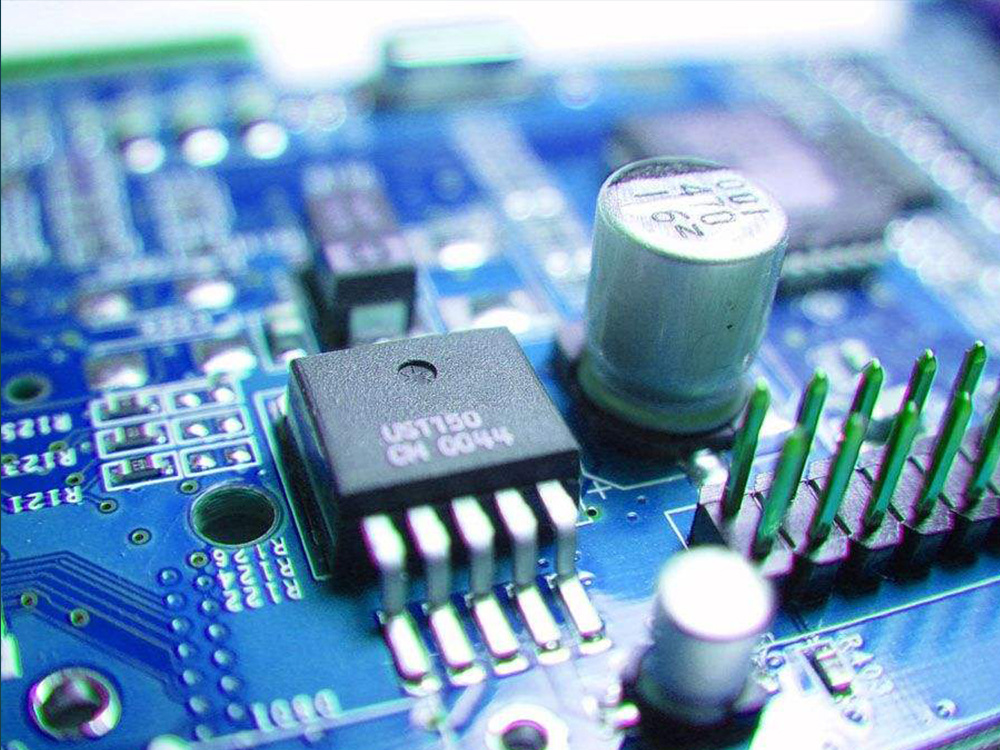

In today's era of countless electronic products, have you ever wondered how those tiny electronic components are assembled? That's where DIP (Dual In-line Package) plugin processing plays a crucial role. Especially in SMT (Surface Mount Technology) factories, DIP plugin processing not only enhances product performance but also impacts overall production efficiency and cost control.

Basic Knowledge of DIP Plugin Processing

First, let's briefly understand DIP plugins. It's a traditional electronic component packaging method, usually with two parallel pins suitable for insertion into holes on a circuit board. Compared to other packaging methods, DIP plugins offer advantages in stability and ease of manual repair. Even in today's high-tech world, it still plays an irreplaceable role in many electronic products.

So, why do SMT factories place such importance on DIP plugin processing? Firstly, it's due to its unique advantages in the production process. DIP plugin processing effectively reduces error rates, especially in complex circuit designs. Imagine having a stable tool when performing a precision task; the quality of the finished product will naturally be greatly improved.

Cost Effectiveness and Production Efficiency

In the electronics manufacturing industry, cost control is paramount. DIP plugin processing helps SMT factories save material and labor costs. Because the assembly process of DIP components is relatively simple, workers can complete tasks faster, thus improving overall production efficiency. This high efficiency not only shortens delivery times but also increases output, ensuring manufacturers have a competitive edge in the market.

At the same time, DIP plugins are widely used in low-to-medium complexity circuit designs, making them more cost-effective for small-batch production. Imagine if you are a small electronics manufacturer facing budget constraints; choosing DIP plugin processing allows you to reduce costs while maintaining product quality, thus winning the favor of more customers.

The Key to Improving Product Quality

You might ask, can DIP plugin processing significantly improve product quality? The answer is yes. Due to the stability of their structure, DIP components can better withstand environmental factors such as temperature changes and humidity. This means that products using DIP plugin processing have a lower probability of performance degradation during long-term use.

In addition, the manual soldering characteristics of DIP plugins are suitable for later maintenance and replacement. For equipment that requires frequent maintenance, DIP plugin processing provides greater convenience. This is essentially like providing a "backup" for the product, making it more competitive in the market.

The Combination of DIP and SMT

In SMT factories, DIP plugin processing and surface mount technology (SMT) are not opposites but complementary. Although SMT has gradually become dominant in modern electronics manufacturing, the advantages of DIP plugins still exist. Many electronic products combine these two technologies to fully utilize their respective strengths.

For example, in some complex circuits, DIP plugins may be needed to carry specific functional modules, while other parts can use SMT to achieve higher density and smaller size. This flexible design approach greatly improves product performance and functionality.

Future Trends

So, how will the importance of DIP plugin processing in electronics manufacturing change in the future? With technological advancements, although more and more new packaging technologies are emerging, DIP plugins will not be completely replaced. Instead, they will continue to play an important role in certain specific areas. Especially in equipment requiring durability and maintainability, DIP plugin processing will continue to hold a place.

In short, DIP plugin processing is undoubtedly an indispensable part of electronics manufacturing. Especially in SMT factories, it not only affects production efficiency and cost control but also ensures product quality and stability. No matter how technology develops, DIP plugin processing will continue to accompany our electronic lives, becoming the gateway to the future.

MORE BUSINESS

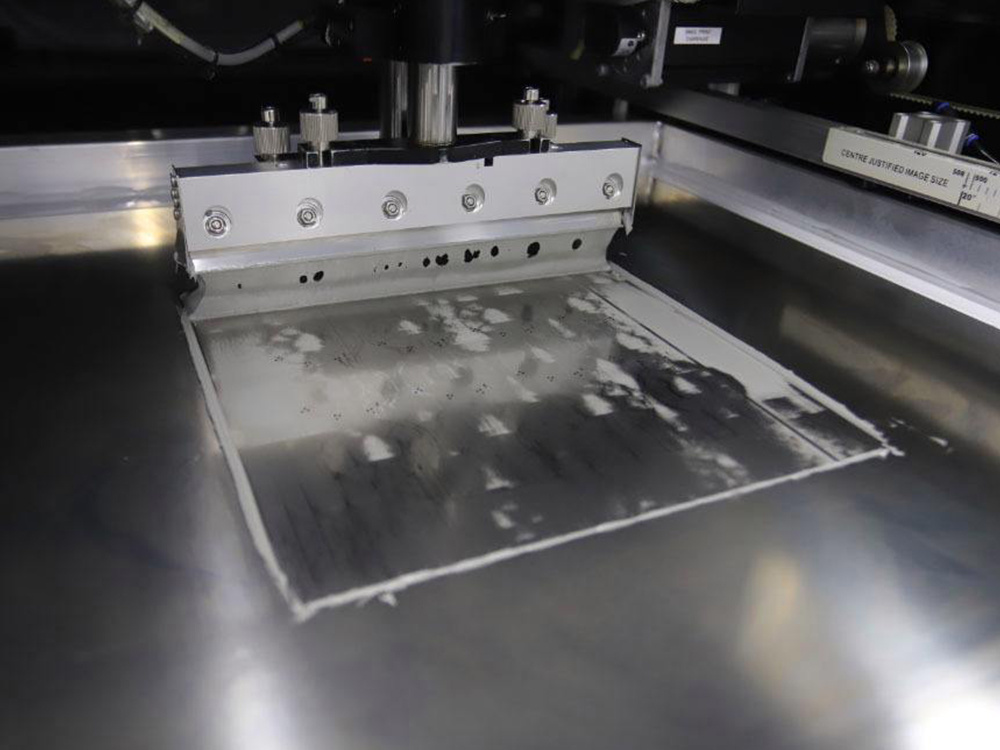

Component Storage and Solder Paste Printing