Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Quality Management

Build a quality system with quality culture, and create attractive and soulful quality

Tongsen Electronics adheres to the PDCA management improvement principle, and under the guidance of the ISO9001 system and IPC-A-610E standard, refines the internal management process, improves the level of supply chain management, and provides customers with high-quality product manufacturing services. We strictly control process design, NPI product introduction, DFM inspection, PCBA manufacturing, quality control points in testing, and personnel training to form a complete quality management system.

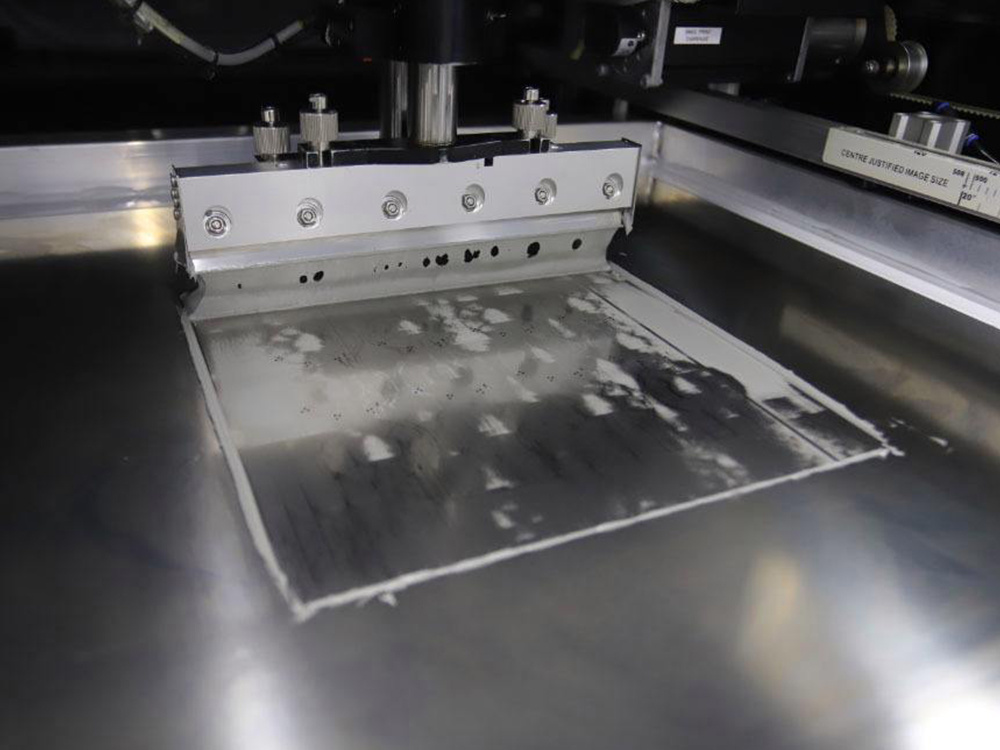

Component Storage and Solder Paste Printing

Sensitive components are stored in a professional constant temperature and humidity box Bake some demanding PCB/IC/BGA for 2-12 hours to remove surface moisture and enhance solderability Use first-line brand solder paste Issuing high-quality laser stencils Complete solder paste freezing, thawing and stirring procedures Equipped with a fully automatic solder paste printing machine to ensure the consistency and reliability of solder paste printing during mass production

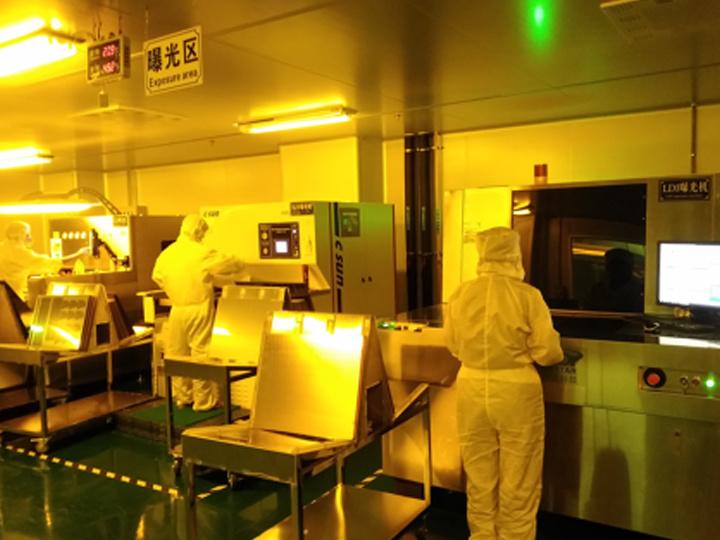

Measuring the thickness of a PCB Check the through holes of the PCB and whether the ink is blocking the holes, etc. Check whether the PCB is warped and deformed, and whether the silk screen is clear Check the PCB for defects such as broken wires, jumpers, etc. Place the PCB in reflow soldering for oven temperature test to check for yellowing or deformation Check whether the batch number, part number and silk screen of incoming electronic components are consistent with the BOM Incoming electronic components are placed on the bare PCB board for pad or through-hole...

Procurement of electronic components

100% purchase according to the brand and item number specified in the customer's BOM (unless the customer agrees in writing to purchase other alternative materials due to the procurement cycle) Purchasing materials through formal channels such as original factories, first-level agents or top traders Can provide first-level agent certificate of origin Have a good centralized procurement advantage, get a shorter procurement cycle, the latest material year, stocking advantages, etc. Provide complete original technical support

New product introduction meeting

Organize sales department, engineering department, production department, purchasing department, quality department and other personnel to hold a new product introduction meeting: • Introduce the customer's project background, product application scope, delivery time and special requirements in detail • Determine internal customer number and product number • Clarify production batches, purchase and delivery quantities • Assess the process difficulty and key quality control points of the project • Clarify the procurement cycle of PCB and electronic components • Propose a draft production plan

We outsource PCB production and strictly control the following key quality points High-quality brand board Choose a well-known circuit board supplier Continuously build supplier relationship management Have the ability to complete 3mil line width and line spacing, multi-layer, HDI, impedance, blind buried via All PCBs delivered to our company must be 100% electrical tested

Check the items of customer's design PCB, BOM, schematic diagram, finished product assembly manual: • Document version and last update time • Process: lead/lead -free • Clear component tag number and silk screen • Including manufacturer's brand and part number, BOM of description and bit number • Confirm the PCB manufacturing process: material, board thickness, copper thickness, number of layers, surface treatment, character color and special process • Reasonable PCB layers and paneling methods • Provide correct SMT patch file