Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

From design to production: How to choose the right SMT processing service?

Surface mount technology (SMT) assembly services play a crucial role in the production of modern electronic products. Whether you're a startup or a large manufacturer, choosing the right SMT assembly factory directly impacts your product quality and market competitiveness. So, how can you find better SMT assembly services? Let's discuss this topic.

Understanding the Basic Concepts of SMT Assembly

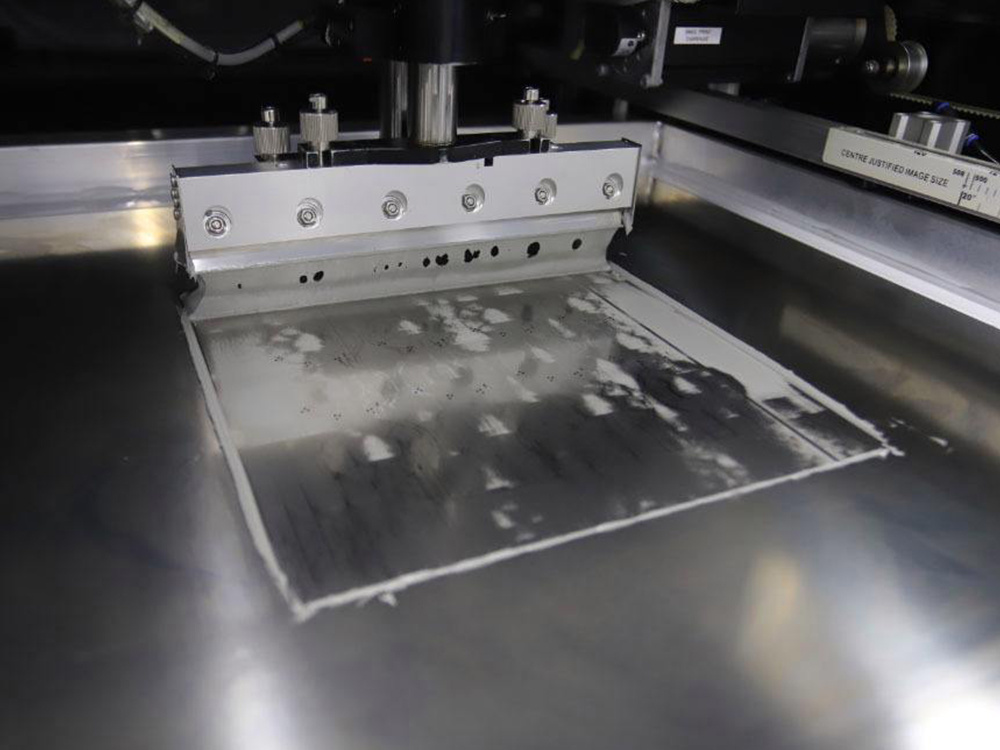

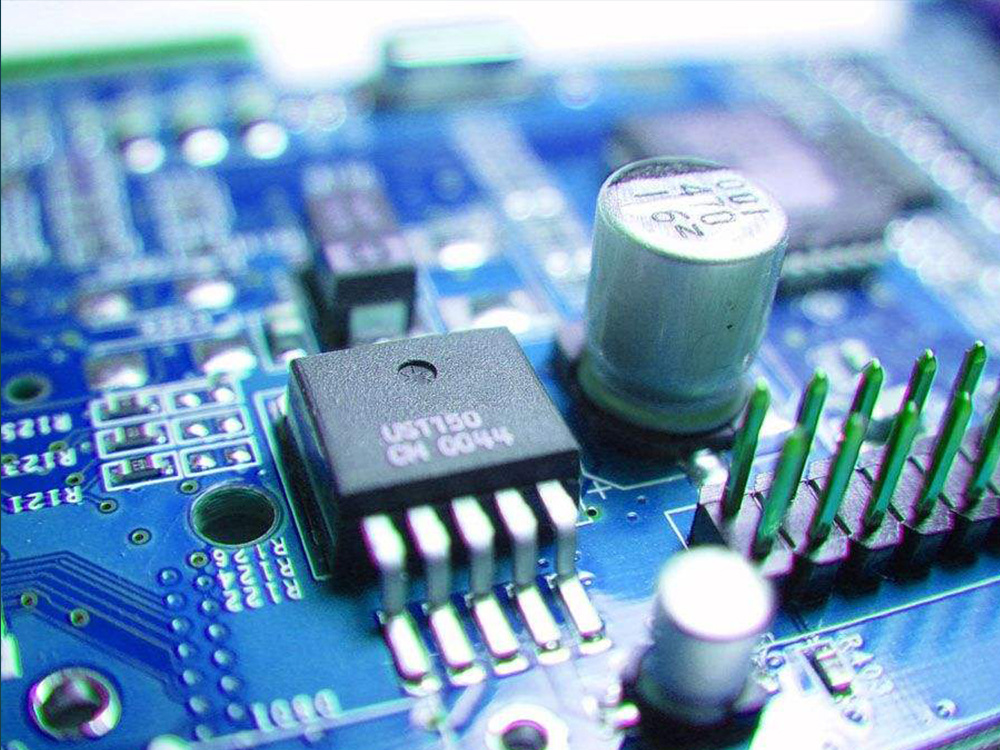

First, let's understand what SMT assembly is. Simply put, SMT assembly is the process of mounting electronic components onto circuit boards using automated equipment. This process involves multiple stages, including component procurement, mounting, soldering, and post-testing. Therefore, choosing an advanced SMT assembly factory ensures seamless integration throughout the production process, avoiding unnecessary losses.

Key Factors in Choosing an SMT Assembly Factory

1. Manufacturer's Qualifications and Reputation

When choosing an SMT assembly factory, the first step is to investigate the manufacturer's qualifications and reputation. You can check their certifications, such as ISO9001, ISO14001, etc. These certifications effectively demonstrate the manufacturer's production management level and quality control capabilities. In addition, referring to customer reviews and feedback can also help you judge the quality of the factory's services.

2. Technical Strength

Technical strength is an important factor affecting the quality of SMT assembly services. An advanced SMT assembly factory should have advanced equipment and technology, such as high-speed placement machines and precision soldering machines, to ensure component mounting accuracy and production efficiency. At the same time, they should have a certain level of technological research and development capabilities to provide customized solutions based on your needs.

3. Production Capacity and Delivery Time

When choosing an SMT assembly factory, production capacity and delivery time are also factors to consider. You need to ensure that they can handle your order volume and deliver on time. When communicating with the manufacturer, you can inquire about their production plan and delivery cycle to ensure that they can meet your requirements.

4. Price and Value for Money

Price is a concern for every business. While price is not the only deciding factor, it should not be ignored. Compare multiple SMT assembly factories, focusing on their pricing details and service content, and choose the option with the best value for money. In this process, don't just look at the price and ignore the importance of quality and service.

5. After-Sales Service

Good after-sales service is also an important criterion for choosing an SMT assembly factory. If problems arise during production, timely and effective after-sales service can help you resolve them quickly, preventing disruptions to the entire production process. Therefore, inquiring about the manufacturer's after-sales service commitments and procedures is an indispensable step in the selection process.

Case Study

Let's look at a simple case. Suppose you are a new audio equipment manufacturer who has just completed the design of a new product. You know this product will be a hit in the market, but you need to find the right SMT assembly factory to realize your design. After comparing several options, you finally choose a reputable SMT assembly factory.

This factory not only has advanced equipment but also extensive experience. They provide personalized services, optimizing the production process according to your needs, ultimately ensuring high product quality and fast delivery. Through this cooperation, your product was successfully launched into the market and received enthusiastic feedback from consumers.

Choosing the right SMT assembly factory is not easy, but it is key to ensuring your product's success. By understanding the manufacturer's qualifications, technical strength, production capacity, price, and after-sales service, you can make better decisions. In this competitive market, finding a trustworthy partner can take your business to the next level.

Behind every successful product is a reliable SMT assembly factory silently supporting you. I hope you can find the right partner on this journey to help your design dreams come true!

MORE BUSINESS

Component Storage and Solder Paste Printing