Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Why are electronics companies choosing SMT surface mount technology processing?

With continuous advancements in technology and evolving market demands, SMT technology will continue to innovate and bring more possibilities and opportunities to the electronics industry. The SMT exhibition editor believes that for electronics companies, keeping up with industry trends and selecting appropriate processing technologies will help enhance competitiveness and gain a first-mover advantage in the market.

In recent years, surface mount technology (SMT) has become increasingly prevalent in the electronics industry. Numerous electronics companies have adopted SMT assembly to improve production efficiency and product quality. Let's discuss the reasons why the electronics industry generally chooses SMT assembly and its advantages.

Definition and Development of SMT Assembly

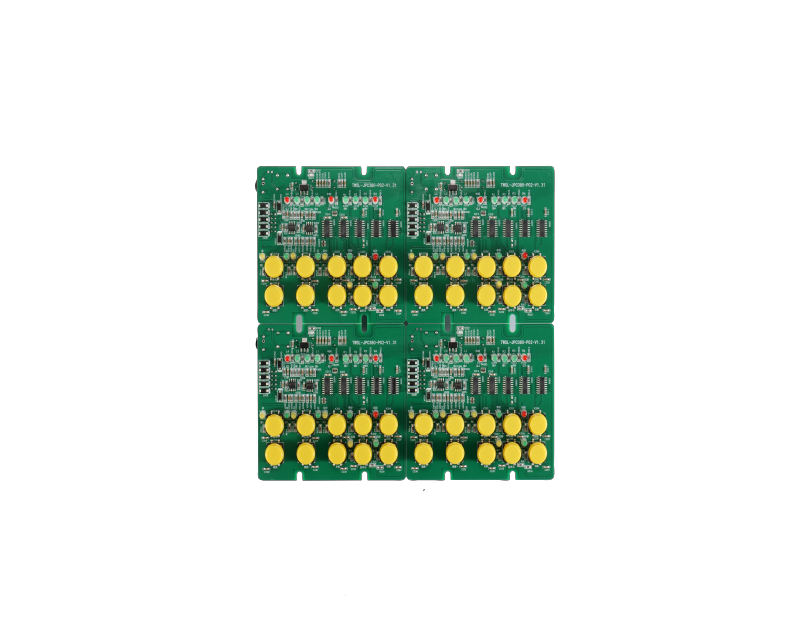

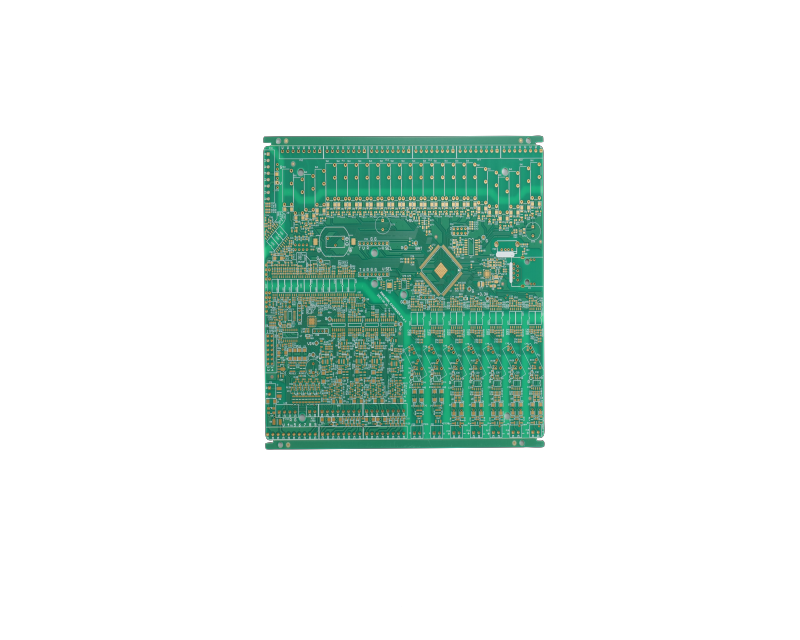

SMT assembly is a technology that mounts electronic components directly onto the surface of a printed circuit board (PCB). It originated in the 1980s. With the increasing miniaturization and integration of electronic products, traditional through-hole insertion technology could no longer meet the demand, leading to the emergence of SMT assembly.

After decades of development, SMT technology has matured and gradually replaced traditional plug-in technology, becoming the mainstream technology in the electronics manufacturing industry.

Reasons for the Electronics Industry Choosing SMT Assembly

High Efficiency: SMT assembly uses automated production lines to achieve high-speed, high-precision mounting, significantly improving production efficiency. Simultaneously, the production cycle is shortened due to the reduction of processes such as insertion and soldering.

High Density: As the functions of electronic products continue to increase, the number of components on the circuit board is also rapidly growing. SMT assembly can closely mount components on the PCB surface, achieving high-density assembly and meeting the needs of miniaturization and thinness of electronic products.

High Quality: SMT assembly uses advanced production processes and equipment to ensure accurate component mounting and soldering, reducing quality problems caused by human factors. Automated production lines also reduce the impact of human factors on product quality.

Low Cost: Although the one-time investment in SMT assembly equipment is high, in the long run, costs are effectively controlled due to increased production efficiency and reduced defect rates. In addition, SMT technology is conducive to standardizing and scaling production processes, further reducing costs.

Application Cases of SMT Assembly in the Electronics Industry

Mobile Phone Manufacturing: With the increasing functions of mobile phones, the number of internal components has increased significantly. SMT assembly allows for high-density assembly of mobile phone motherboards, ensuring the miniaturization and thinness of mobile phones.

Automotive Electronics: Automotive electronics have extremely high requirements for safety and reliability. SMT assembly can provide high-quality assembly processes to ensure the stable operation of automotive electronic products in harsh environments.

Smart Home: The smart home market has been booming in recent years, with a wide variety of products. The high efficiency and low cost of SMT assembly meet the needs of rapid iteration and diversified production of smart home products.

Medical Devices: Medical devices have very high requirements for product quality and stability. SMT assembly can ensure that the electronic components in medical devices are accurately and reliably assembled, improving the safety and service life of medical devices.

The electronics industry chooses SMT assembly mainly due to its advantages of high efficiency, high density, high quality, and low cost.

With continuous technological advancements and changing market demands, SMT technology will continue to develop and innovate, bringing more possibilities and opportunities to the electronics industry. The SMT exhibition editor believes that electronics companies should keep up with industry trends and choose appropriate processing technologies to enhance competitiveness and gain a market advantage.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs