Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Basic information and calculation skills for SMT chip processing

The following process defects are prone to occur during production: unqualified glue point size, drawing, glue staining the solder pad, poor curing strength and easy chipping. To solve these problems, the technical process parameters should be studied comprehensively to find solutions.

In today's rapidly developing economy, with improvements in all aspects of people's lives, SMT surface mount technology processing may not be very familiar to everyone. Today, let's talk about SMT surface mount technology processing. What information is there about SMT surface mount technology processing? What are the key calculation points? Below, I will introduce the basic information and calculation techniques of SMT surface mount technology processing.

I. Detailed Explanation of SMT Surface Mount Technology Processing

1. SMT Surface Mount Technology Adhesive and its Technical Requirements:

The adhesive used in SMT is mainly used in the wave soldering process of surface mount devices such as chip components, SOT, and SOIC. The purpose of fixing surface mount components to the PCB with adhesive is to avoid the possible detachment or displacement of components under the impact of high-temperature waves.

Generally, epoxy resin thermosetting adhesives are used in production, not acrylic adhesives (which require UV curing).

2. Requirements for SMT Surface Mount Technology Adhesive:

(1) The adhesive should have good thixotropic properties.

(2) No stringing.

(3) High wet strength.

(4) No bubbles.

(5) Low curing temperature and short curing time of the adhesive.

(6) Sufficient cured strength.

(7) Low moisture absorption.

(8) Good rework characteristics.

(9) Non-toxic.

(10) Easily identifiable color for easy inspection of glue point quality.

(11) Packaging. The packaging type should be convenient for equipment use.

3. Process control plays a crucial role in the dispensing process.

The following process defects are prone to occur in production: unqualified glue point size, stringing, adhesive staining of pads, poor curing strength, easy chip dropping, etc. To solve these problems, the various technical process parameters should be studied comprehensively to find solutions.

(1) Size of dispensing amount

Based on work experience, the diameter of the glue point should be half of the distance between the pads, and the diameter of the glue point after mounting should be 1.5 times the diameter of the glue point. This ensures sufficient adhesive to bond the components while avoiding excessive adhesive staining of the pads. The amount of dispensing is determined by the length of the rotation time of the screw pump.

In practice, the pump's rotation time should be selected according to the production conditions (room temperature, adhesive viscosity, etc.).

(2) Dispensing pressure (back pressure)

The dispensing machine currently used uses a screw pump to supply the dispensing needle tube with a pressure to ensure sufficient adhesive supply to the screw pump. Too much back pressure can easily cause adhesive overflow and excessive adhesive. Too little pressure will cause intermittent dispensing, leakage, and thus defects.

The pressure should be selected according to the adhesive of the same quality and the ambient temperature. High ambient temperature will reduce the viscosity of the adhesive and improve its fluidity. At this time, the back pressure needs to be lowered to ensure the supply of adhesive, and vice versa.

(3) Adhesive temperature

Generally, epoxy resin adhesives should be stored in a refrigerator at 0-50°C. When using, they should be taken out 1/2 hour in advance to allow the adhesive to fully match the working temperature. The working temperature of the adhesive should be 23-25°C. The ambient temperature has a great influence on the viscosity of the adhesive. If the temperature is too low, the glue point will become smaller, and stringing will occur.

A 5°C difference in ambient temperature will cause a 50% change in dispensing volume. Therefore, the ambient temperature should be controlled. At the same time, the ambient temperature should also be guaranteed. Low humidity will cause the glue points to dry easily, affecting the bonding strength.

(4) Viscosity of the adhesive

The viscosity of the adhesive directly affects the quality of dispensing. If the viscosity is high, the glue point will become smaller, and even stringing will occur. If the viscosity is low, the glue point will become larger, and it may penetrate the pads. During the dispensing process, appropriate back pressure and dispensing speed should be selected for adhesives with different viscosities.

For the adjustment of the above parameters, SMT processing manufacturers should adopt a point-to-area approach. Any change in a parameter will affect other aspects. At the same time, the occurrence of defects may be caused by multiple aspects. Possible factors should be checked one by one to eliminate them.

In short, in production, the parameters should be adjusted according to the actual situation, ensuring both production quality and efficiency.

II. Calculation Methods for SMT Surface Mount Technology Processing

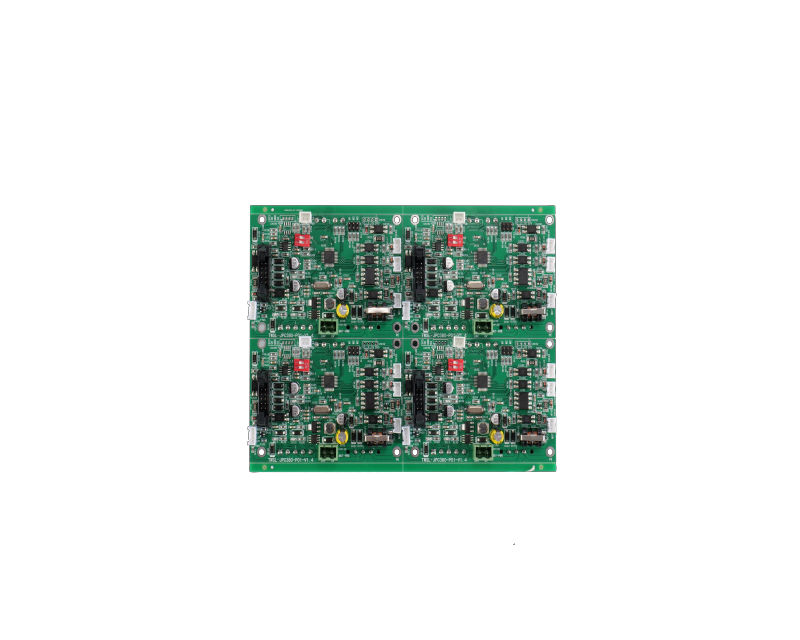

1. SMD chip components: 2 pins are counted as 1 point; 0402 components are calculated at 0.015 per point, and 0603-1206 components are calculated at 0.015 per point.

2. Through-hole components: 1 pin is counted as 1 point; calculated at 0.015 per point.

3. Sockets: 4 pins are counted as 1 point; calculated at 0.015 per point.

4. Ordinary ICs: 4 pins are counted as 1 point; calculated at 0.015 per point.

5. High-pin-count ICs: 2 pins are counted as 1 point; calculated at 0.015 per point.

6. BGA: 2 pins are counted as 1 point; calculated at 0.02 per point.

7. Machine-mounted large components are calculated by doubling the volume of the components.

8. Additional fees are calculated at 20 yuan per hour.

9. This quotation does not include testing fees.

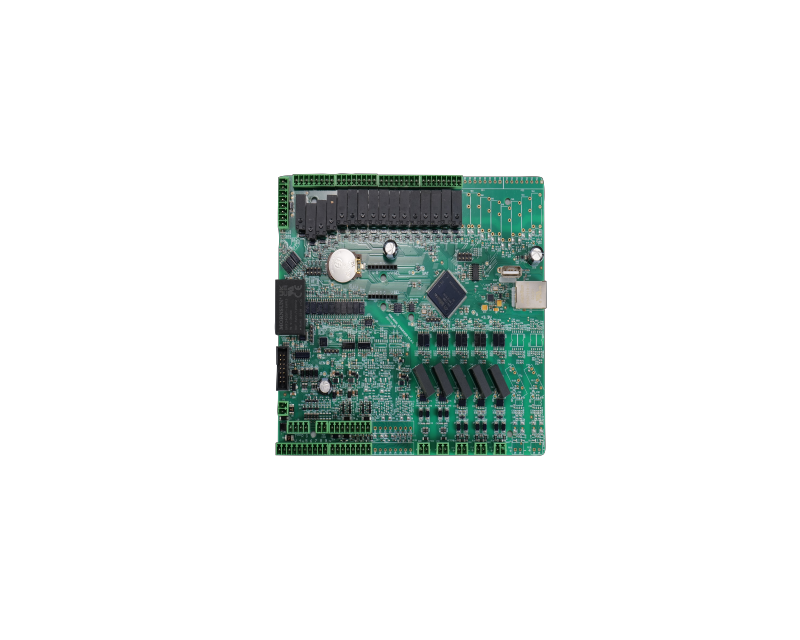

10. Understanding the SMT production process and the content of each process:

Loading - Printing solder paste - Mounting components - Visual inspection - Reflow oven - Ultrasonic cleaning - Cutting - Appearance inspection - Packaging

(Some products require IC programming and PCBA functional testing)

11. Calculating the number of chip components:

SMT processing fees are generally calculated based on the number of components. One surface mount component (resistor, capacitor, diode) counts as one point, and one transistor counts as 1.5 points.

For ICs with less than 50 pins, two pins count as one point; for ICs with more than 50 pins, four pins count as one point. Count all surface mount points on the PCB.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs