Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

How are PCBs manufactured? A beginner's guide to PCB manufacturing (Part 1)

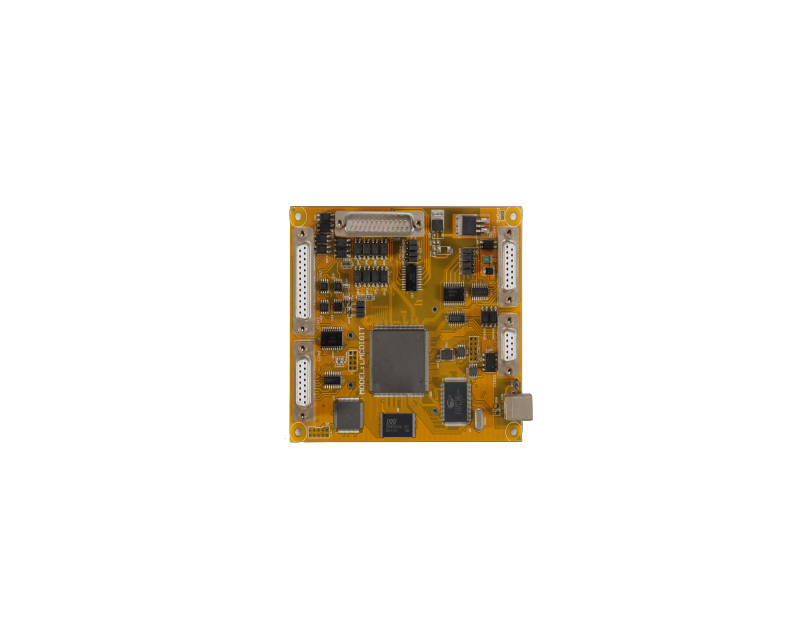

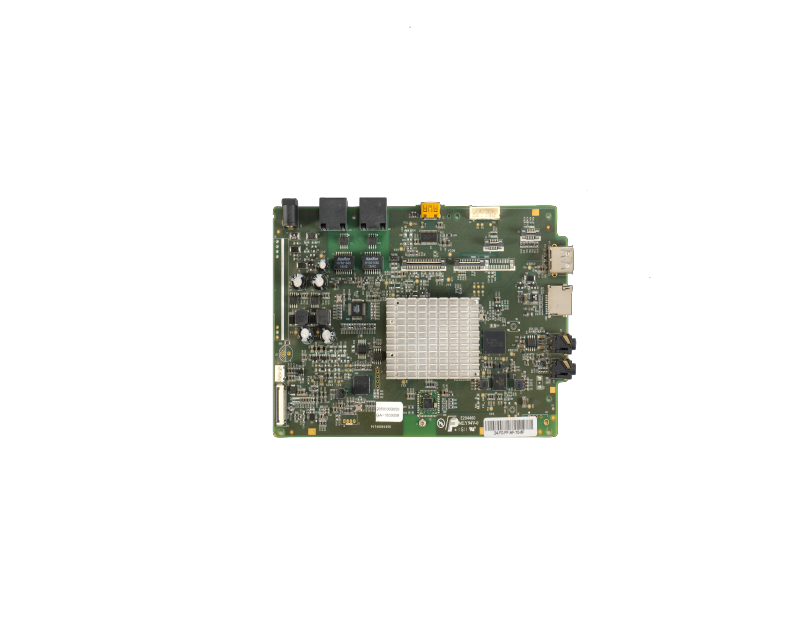

You must remember that these are only the building blocks of a PCB! A complete PCB also includes many other components, such as resistors, capacitors, transistors, diodes, and integrated circuit chips, which provide functionality and enhance the reliability of the PCB.

Manufacturing electronic components and devices is a highly complex process. Take a mobile phone, for example: from the screen to the frame and communication equipment, each component is intricate, the result of decades of research. However, one component stands above the rest, forming the core of most electronic devices: the printed circuit board (PCB). From smartphones and laptops to household appliances, these devices would not function without a PCB.

Whether you are a tech enthusiast, an aspiring engineer, or simply curious about the inner workings of your favorite electronic gadgets, understanding how PCBs are made is a necessary step in understanding the essence of modern electronics production. But it's more than that: although a PCB was invented over a century ago, the technology behind it continues to advance. The wires on PCBs are getting thinner, the boards more complex to handle all the electrical connections needed for modern devices, and design practices are constantly changing to better accommodate newer, smaller electronic components. Even the way they are assembled is changing.

Despite all these changes, and despite the varied methods of manufacturing boards, they all follow similar (even identical) steps. In this guide, we will take you through the manufacturing process of a printed circuit board from start to finish. How PCBs are made, the outer layers, the copper layers, and the electronic components: after reading this, you will know this and more!

Background: Fundamentals of Circuit Board Manufacturing

Printed circuit boards (commonly called PCBs) are used in a wide variety of devices, from simple pagers and radios to powerful radar systems and computers. These circuits are created by placing a thin layer of conductive material onto an insulating board (called substrate material). Tiny electronic components are then placed on the substrate and connected to these circuits via soldering.

Printed circuit boards (PCBs) come in various forms. There are three main types:

Single-sided circuit boards,

Double-sided circuit boards,

Multilayer circuit boards.

Single-sided boards only have components on one side of the substrate. Double-sided circuit boards are used when there isn't enough space on a single-sided PCB to accommodate all the components. Holes drilled into the substrate connect the circuits on both sides of the board, which are coated with conductive material.

The third type is multilayer boards, which are like a sandwich, with multiple printed circuit boards separated by insulating layers. Components on the outer layers of the board are connected to the correct inner layers via drilled holes. While single-sided and double-sided boards have simpler circuit patterns, the ingenious use of multilayer circuit boards makes many modern devices possible.

Despite these three types being quite different, the manufacturing process only diverges after the initial layers are created, and that's when the complexity truly emerges. Depending on the form, size, and number of layers of the PCB, the circuit board manufacturing process may involve 20 or more separate stages.

Of course, the more complex the printed circuit board, the more steps are required for manufacturing. Think of it like a jigsaw puzzle—every piece must fit just right. In PCB manufacturing, if you skip or simplify any steps, it can lead to major problems with the finished PCB, sometimes even complete failure. On the other hand, if each step is carefully and precisely completed, the final PCB will be reliable and durable, a mainstay of many of the electronic products we know and love!

Key Components of a Printed Circuit Board

When asking "How are printed circuit boards made?", one topic we need to explore is the fundamental building blocks of a PCB. Whether for casing, communication, or insulation, these building blocks are key to how a PCB and its many components function. Like a house, if you don't get the fundamental building blocks right, the whole thing will collapse.

A standard PCB consists of the following main parts:

Substrate

This is the backbone of the PCB, the core foundation of its main layers. A common material for manufacturing PCB substrates is fiberglass-reinforced epoxy resin (FR-4) copper foil, due to its strength and durability. Ceramic-filled PTFE composites are used in PCBs used in high-frequency application devices. Meanwhile, cyanate esters or polyimides are used in high-temperature situations. In some cases, less expensive alternatives such as paper-reinforced phenolic resin and bonded copper foil are also used, especially in household appliances where affordability is key!

Prepreg

Prepreg is like the glue that holds everything together. It is made of fiberglass cloth soaked in partially cured epoxy resin, used to bond the layers of a PCB together under high temperature and pressure. The prepreg is located below the substrate layer, with copper sheets added below it.

Metal Foil

This is a thin copper foil that can be made into conductive lines and pads. The thickness varies. Copper foil is indispensable for its electromagnetic shielding and anti-static properties. Not only does its thickness vary, typically between 0.5 ounces (17 micrometers) and 3 ounces (105 micrometers), but depending on the type of printed circuit board, it can be classified as single-sided, double-sided, and self-adhesive.

Coatings

Coatings act as a protective layer for the PCB, acting as its skin, so to speak. There are many types of coatings, and the choice of coating depends on the working environment of the printed circuit board. Common ones are solder resist, used to protect the copper from environmental influences; and silkscreen, used to display data such as component numbers, logos, symbols, switch settings, and test points.

Adhesive Film

Adhesive films or sheets are commonly used in multilayer PCBs, serving multiple functions including protecting lines and other fragile components, thermal insulation, and anti-static properties. In many ways, they are similar to the glue used in the lamination of multilayer PCBs.

Through-Holes and Through-Hole Filling

Through-holes are tiny holes that allow the multiple layers of a printed circuit board to communicate. In high-density interconnect boards, through-holes are often filled with electroplated resin or conductive paste to provide additional protection and insulation. When designing through-holes on a PCB, the resin content, aspect ratio of the hole, and thickness of the core are all important considerations.

You must remember that these are just the building blocks of a PCB! A complete PCB also includes many other components such as resistors, capacitors, transistors, diodes, and integrated circuit chips, which provide functionality and enhance the reliability of the PCB.

Next

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs