Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

How does SMT (Surface Mount Technology) affect and accelerate PCB production time?

SMT, with its powerful advantages, has surprisingly become the main standard for design and manufacturing. Essentially, they can be used in any situation requiring high reliability and high-volume PCB production.

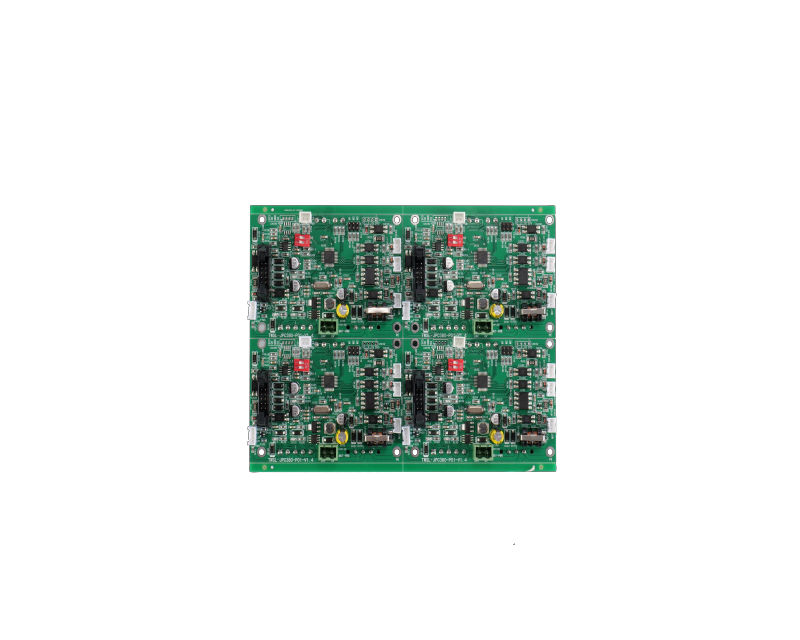

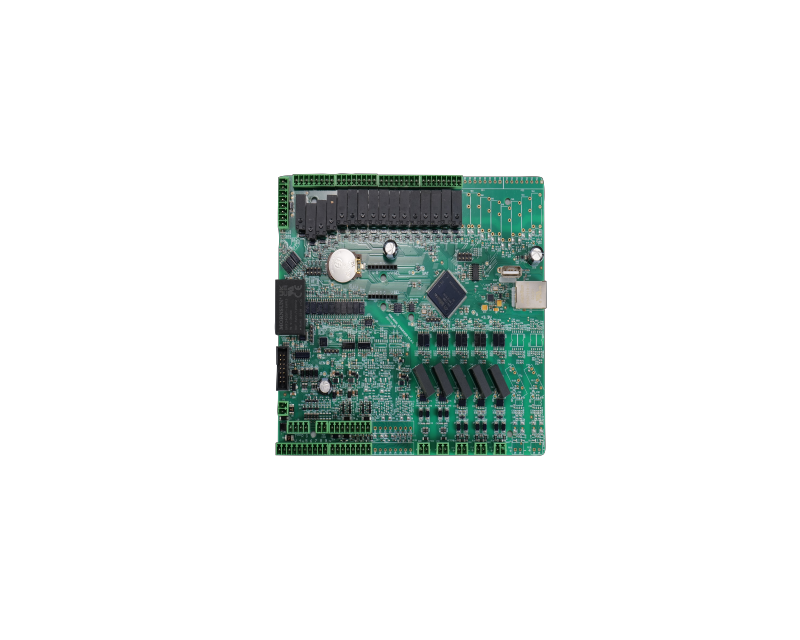

Most mass-produced electronic hardware today is manufactured using surface mount technology, or SMT.

Surface Mount Technology:

Basic Surface Mount Technology (SMT) The concept of basic through-hole manufacturing continues to offer significant improvements. With SMT, no holes need to be drilled in the bare board PCB. Instead, all that is done is the use of solder paste. Besides adding a lot of speed, this also simplifies the process considerably. While SMT mounted components may not possess the strength of through-hole mounting, they offer numerous other advantages to offset this issue.

Differences between SMT and Through-Hole include:

1. Space problems prevalent in through-hole mounting can be solved by using surface mount technology. SMT also offers design flexibility as it gives PCB designers the freedom to create specialized circuits. Reduced component size means more components can be accommodated on a single board, and fewer boards are needed.

2. SMT mounted components are leadless. The shorter the lead length of surface mount components, the lower the transmission delay and the lower the package noise.

3. Higher component density per unit area due to allowing double-sided mounting of components, suitable for mass production, thus reducing costs.

4. Reduced size, increased circuit speed. This is also one of the main reasons why most manufacturers choose this method.

5. The surface tension of the molten solder pulls the component into alignment with the pad. This in turn automatically corrects any minor errors that may occur during component placement.

6. SMT has proven to be more stable under conditions of vibration or significant shock.

7. SMT parts generally cost less than comparable through-hole parts.

Because no drilling is required, SMT can significantly reduce production time. Furthermore, SMT components can be mounted at rates of thousands per hour, while through-hole mounting is less than a thousand. This in turn allows products to be produced at the desired speed, further shortening time to market.

All this is not to say that SMT does not have inherent drawbacks. When SMT is used as the sole method of connection for components that experience significant mechanical stress, it can be unreliable. Components that generate significant heat or experience high electrical loads cannot use SMT mounting. This is because the solder will melt at high temperatures.

Therefore, through-hole mounting can continue to be used when special mechanical, electrical, and thermal factors exist that render SMT ineffective. Furthermore, SMT is not suitable for prototyping, as components may need to be added or replaced during the prototyping phase, and high component density boards may be difficult to support.

With their considerable advantages, it is no surprise that SMTs have become the dominant standard for design and manufacturing today. Essentially, they can be used in any situation requiring high reliability and high-volume PCB production.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs