Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

How does a circuit board work? Explanation of PCBs and their different components

In short, PCBs are crucial to the development of modern electronics. PCBs are not only the foundation of electronic devices, but also enable them to function as intended. As electronic design continues to advance, understanding the role of PCBs remains critical to shaping the future of technology.

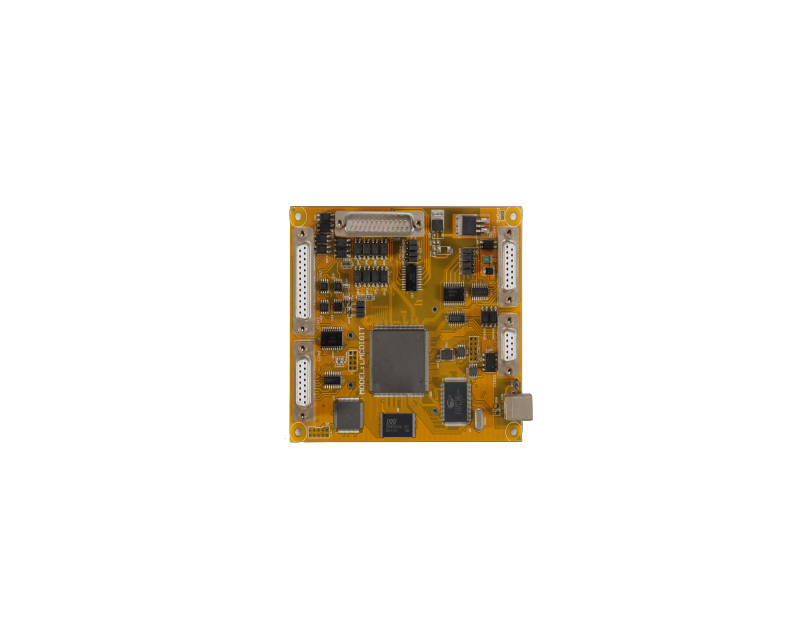

Printed Circuit Boards (PCBs) are indispensable components in embedded engineering. They provide an organized platform for integrating electronic components, used in developing various types of electronic devices. Each interconnected component on a PCB plays a crucial role in determining the functionality and performance of the electronic device. In this blog, we will delve into what printed circuit boards are, their different components, various types, and their role in the world of embedded systems.

What is a Printed Circuit Board (PCB)?

A PCB is a flat plate made of a non-conductive material (such as fiberglass or epoxy resin) with thin layers of conductive copper traces etched onto its surface. While circuit boards can be handcrafted using soldering techniques, the term "printed" in PCB refers to the process of creating circuit patterns on the board's surface using a combination of printing and chemical etching techniques. Various components such as resistors, capacitors, transistors, and integrated circuits (ICs) are mounted on the PCB surface and connected to the copper traces via soldering. These copper traces allow signals to flow between components, enabling the device to perform its dedicated function.

PCBs are widely used in a variety of electronic devices we use daily, including smartphones, computers, medical equipment, automotive systems, industrial equipment, and more.

What role do Printed Circuit Boards (PCBs) play in embedded systems?

PCBs are the backbone of electronic devices, contributing to the operation and functionality of electronic equipment.

Electrical Signal Pathways

A primary function of PCBs in embedded devices is to facilitate the transmission of electrical signals between components mounted on the board. These signals travel along copper pathways, carrying data and instructions and enabling information exchange.

Components of a Printed Circuit Board

Different PCB components work together to form functional electronic circuits. The specific components used depend on the device's function, design requirements, and performance specifications. Some common components found on PCBs include:

Passive components such as resistors, capacitors, and inductors used for signal processing, filtering, and voltage regulation. Active components such as integrated circuits (ICs) that include microcontrollers or memory chips, as well as transistors that act as switches or amplifiers and diodes that control the direction of current flow. Connectors and interfaces such as headers and interface connectors that provide connection points to other wires or PCBs, such as USB or HDMI ports. Power management components such as voltage regulators that stabilize and regulate voltage levels in the circuit.

Sensors and actuators help facilitate responsive interactions, including detecting physical or environmental conditions (such as temperature) or converting electrical signals into physical actions.

PCB Communication

In summary, these components and electrical signals establish a framework for communication and data exchange, facilitating connections between each element, enabling the device to fulfill its intended role. These components can utilize protocols such as SPI, I2C, or UART to exchange data efficiently and reliably, ensuring the proper operation and performance of the electronic device. A simple example of communication between components on a PCB could include the interaction between a central processing unit (CPU) and an SPI EEPROM. The CPU communicates with the SPI EEPROM by addressing the EEPROM, specifying the memory location to access, and then reading or writing data as needed, thus facilitating the storage or retrieval of information between the CPU and EEPROM.

Types of Printed Circuit Boards

There are various types of PCBs, each designed for a specific purpose or application. Some common types include:

Single-sided PCBs:

Have conductive traces on one side only, often used for simpler electronic circuits due to their cost-effectiveness and ease of manufacturing.

Commonly used in applications such as calculators, radios, and LED lights.

Double-sided PCBs:

Have conductive traces on both sides, allowing for more complex circuit designs and higher component density compared to single-sided PCBs.

Due to their versatility, they are commonly used in applications such as mobile phones, printers, routers, and modems.

Multilayer PCBs:

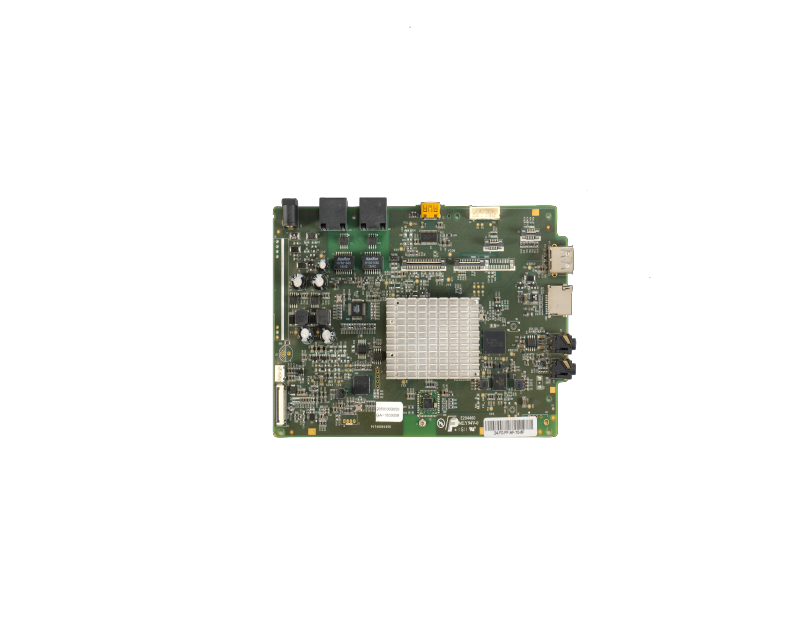

Contain three or more layers of conductive traces, separated by insulating layers. These boards offer higher circuit density, smaller size, and improved performance, suitable for more advanced electronics.

Common applications include computers, laptops, server motherboards, and advanced medical equipment such as MRI machines.

Rigid PCBs:

Constructed using rigid, inflexible materials such as FR-4, providing stability and mechanical support for electronic components.

They are the standard for most electronic devices where rigidity is crucial, such as home electronics (TVs, DVD players) and consumer electronics (smartphones, cameras).

Flexible PCBs (Flex PCBs):

Made from materials such as polyimide, allowing them to be bent or folded without damage.

Flexible PCBs are ideal for applications requiring compact, lightweight, or bendable designs, such as wearable electronics (smartwatches) and foldable smartphones or curved displays.

Rigid-flex PCBs:

Integrate both rigid and flexible substrates into a single board, combining the advantages of both. They enable complex three-dimensional layouts, reduced assembly time, and improved reliability.

These PCBs are commonly used in military equipment, aerospace, medical devices, and more.

PCBs in Today's Electronics

Over the years, circuit boards have undergone significant transformations, evolving from simple wiring basic designs to complex structures with multiple layers and compact components. Thanks to advancements in surface mount technology, circuit boards now benefit from automated assembly and high-density compatibility, enabling the mass production of smaller and more compact boards. These advantages have resulted in smaller yet more powerful devices across various industries, from consumer electronics to aerospace and medical applications.

Prototyping and Testing PCB Designs

During the development and testing manufacturing stages of today's electronic devices, engineers may frequently use host adapters for system emulation and protocol analyzers to monitor data transmission between components on the PCB. These tools aid in debugging and optimizing system performance.

Conclusion

In short, PCBs are crucial to the development of modern electronics. PCBs are not only the foundation of electronic devices, but also enable them to function as intended. As electronic design continues to advance, understanding the role of PCBs remains vital to shaping the future of technology.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs