Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

SMT PCB Assembly Process: What Engineers Should Know

Most surface mount technology (SMT) components on the PCB will be assembled using automated pick-and-place equipment. To this end, the raw circuit boards and components must be prepared for production. This is first verified by the CM's inspection team. Once completed, the boards will be prepared for assembly using the following process:

Most surface mount technology (SMT) components on the PCB will be assembled using automated pick-and-place equipment. To this end, the raw circuit boards and components must be prepared for production. This is first verified by the CM's inspection team. Once completed, the following process is used to prepare the boards for assembly:

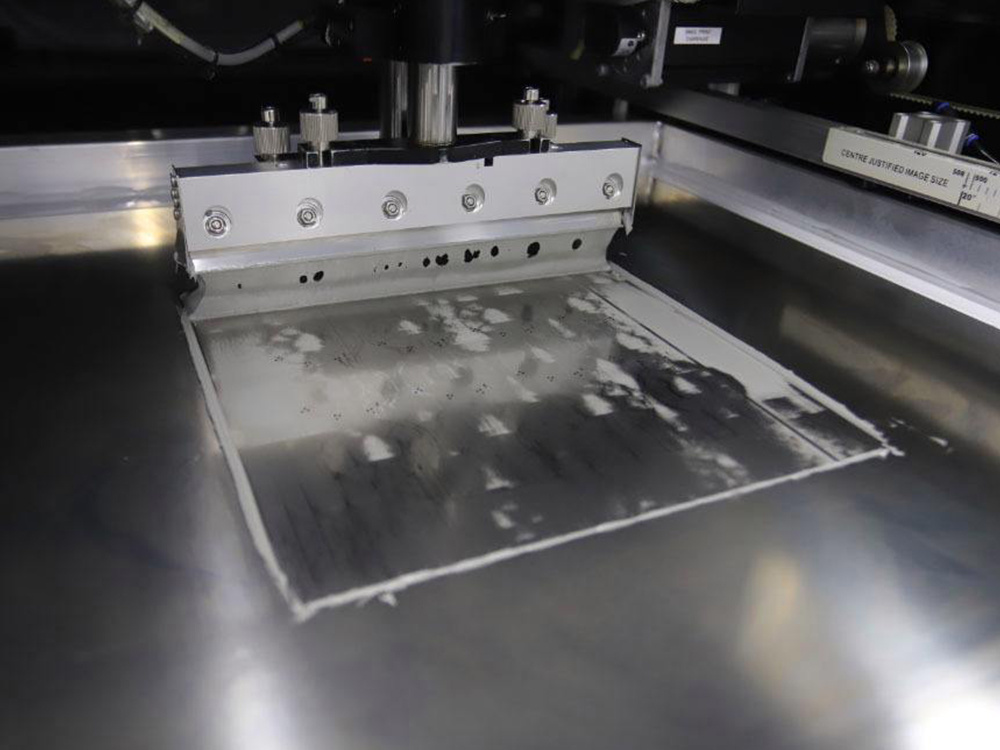

Solder Paste Application: Using a stencil designed from the same CAD output files used to build the raw PCB, solder paste is applied to the SMT pads on the board. The paste is kept in a controlled cold environment, and once applied to the board, the time the board waits for assembly is limited.

Solder Paste Inspection: Once the solder paste is applied, the board goes through solder paste inspection (SPI). Similar to the automated optical inspection (AOI) tools used after assembly, SPI assesses solder paste placement, the physical volume of paste applied, and other key parameters.

Repeat Process for Secondary Side: If the board has SMT components on both sides, the process is repeated for the secondary side. At this point, the time the solder paste on the board is exposed to room temperature is also tracked.

While the boards are being prepared for assembly, another department in the factory is preparing the parts. Parts will be organized into kits, then the circuit boards are assembled:

Kitting Bill of Materials (BOM): The CM will take your BOM data along with the relevant component barcode information to create the kitting BOM.

Components are Kitted: Using the kitting BOM barcodes, components are pulled from inventory and added to the kit. Once full, the kit is forwarded to the pick-and-place machines on the SMT production line.

Prepare Placement Components: The automated pick-and-place machines use a cassette to hold each type of component to be assembled, and the parts from the kit are now loaded into the cassettes. Each cassette has its own unique key that matches the assembly kit BOM, so the machine knows which cassette holds which parts.

Once the correct parts are loaded into the cassettes, the pick-and-place machines are programmed using placement data, and the solder paste-coated boards are ready, the SMT assembly line can begin.

SMT Components Not Suitable for Automated Assembly

While most components will be placed using automated pick-and-place machines, some cannot. This can be for a variety of reasons:

Too Light: Some components are not heavy enough, so the mass-to-adhesion is poor for automated placement equipment requiring manual soldering.

Heat Stress: Other components may be too sensitive to heat for the reflow oven. These components must be assembled after the normal assembly process to protect them.

Robust Solder Joints: Certain components (such as connector leads) require more robust solder joints. These parts will be hand-soldered to meet this requirement.

Panel Separation: Some components may be damaged when individual boards are separated from the assembly panel. In this case, the components will be assembled after the board is separated from the panel.

To accommodate most manual assembly needs, CMs typically install manual rework stations on the automated assembly line. This allows for immediate inspection and correction of parts that may have design for manufacturing (DFM) violations before the parts enter the reflow oven.

Additionally, some boards have very small assembly volumes and do not have dedicated shipping containers optimized for automated assembly to hold their components. Whether these parts are unusually configured, or unique and expensive, they must be placed manually before the board can go through reflow.

Once the parts are placed, the board can enter the solder reflow oven to complete the assembly process.

How Using a High-Quality CM Will Benefit Your PCB Assembly

There are two things you need to do to ensure your printed circuit boards are assembled the way you want them to be. One is to provide your PCB contract manufacturer with complete and correct design data. Make sure to work with them early so you understand the data they need, and ask questions if you are unclear on any of these requirements.

The second is to find a PCB contract manufacturer with a well-established process that is based on years of experience in printed circuit board manufacturing. For example, a CM specializing in small-batch assembly should have regular checkpoints set up on the production line to prevent problems from cascading into later assembly steps.

At VSE, we understand the need for small-batch production and building quality first-article boards. If any problems arise during assembly, we will catch and correct them through checkpoints before they move to the next step in production.

Furthermore, the processes we implement and the equipment we use are designed for parallel activities. For example, the next job can be set up on the pick-and-place machine while the current job is still running. This can help reduce the time and cost that other PCB CMs charge you to make your boards.

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs