Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Countermeasures for insufficient solder in wave soldering during PCBA processing

Countermeasures for insufficient solder in wave soldering during PCBA processing

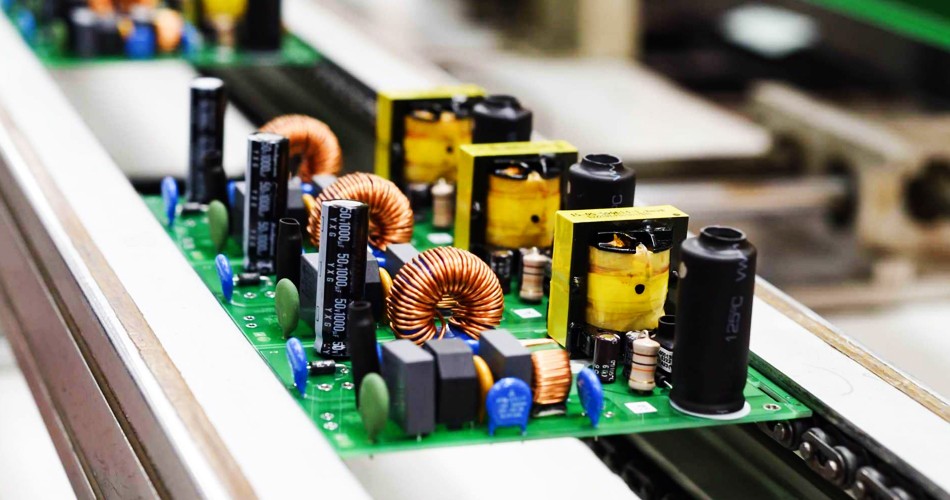

In the wave soldering process of through-hole components on PCBAs, solderability is crucial. Good solderability directly impacts the reliability of solder joints. Poor solderability after wave soldering can easily lead to problems such as cold solder joints.

Wave Soldering Solderability Requirements:

The solderability of wave soldering joints generally needs to reach 75% or more, meaning the visual inspection solderability should be higher than 75% of the board thickness; solderability between 75% and 100% is acceptable. During wave soldering, heat is quickly absorbed by the PCB. Insufficient soldering temperature will result in poor solderability. To provide the PCB with more heat, the solder depth can be adjusted according to different PCBs.

Factors Affecting Wave Soldering Solderability:

Poor wave soldering solderability is mainly related to raw materials (PCBs, components), wave soldering process, the use of flux, and the level of manual soldering.

Raw Material Factors:

Normally, melted solder has strong permeability, but not all metals can be penetrated. For example, aluminum forms a dense protective layer on its surface, making it difficult for other molecules to penetrate its molecular structure. Additionally, if the metal surface is oxidized, solder penetration is difficult and requires flux treatment or cleaning of the oxide layer.

Wave Soldering Process Factors:

Poor solderability is closely related to the wave soldering process and requires re-optimization of welding parameters, such as wave height, temperature setting, welding time, and moving speed. The track angle can be appropriately reduced, increasing the wave height to increase the contact area between the solder and the pad; then, the wave soldering temperature can be appropriately increased. Higher temperatures increase solder permeability, but must remain within the component's tolerance. Finally, the transport speed can be reduced, increasing preheating and welding time to allow the flux to fully remove surface oxides, penetrate the solder joints, and improve solderability.

Flux Factors:

Surface oxides and preventing re-oxidation during soldering; improper flux selection, uneven spraying, and insufficient or excessive use can all lead to poor solderability. First, use a reputable brand of flux for better results. Regularly check the flux nozzle to prevent clogging or damage.

Manual Soldering Factors:

In wave soldering quality inspection, some components only form conical solder joints on the surface, without solder penetration through the hole, resulting in cold solder joints. Such problems usually occur in manual soldering, mainly due to insufficient soldering temperature or too short soldering time. Poor wave soldering solderability easily leads to cold solder joints, increasing the cost of manual rework. Selective wave soldering has much better solderability than wave soldering. If the product has high requirements for welding quality and solderability, selective soldering can be used to reduce problems with poor solderability to some extent.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs