Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Fundamental Knowledge of PCB Materials

By understanding the functions of PCB materials and their impact on circuit board properties, designers can make informed decisions when selecting materials for their projects.

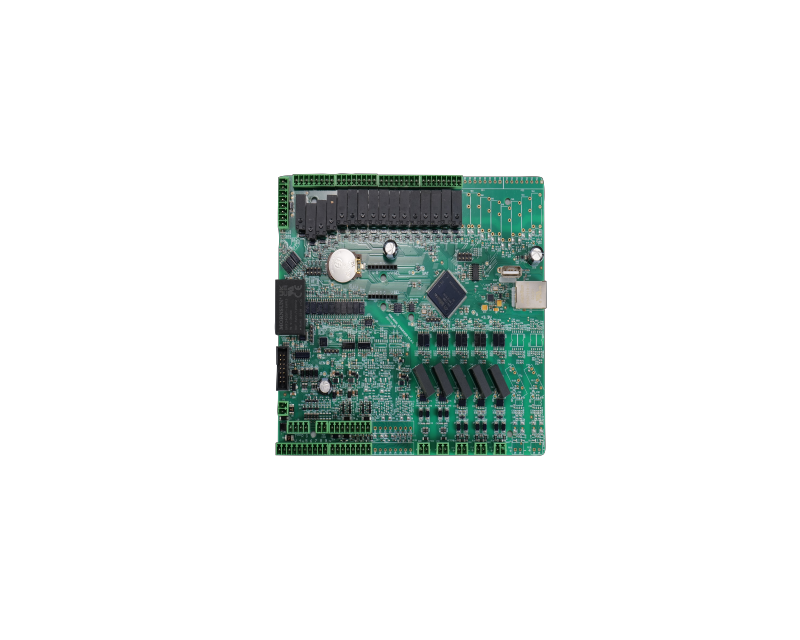

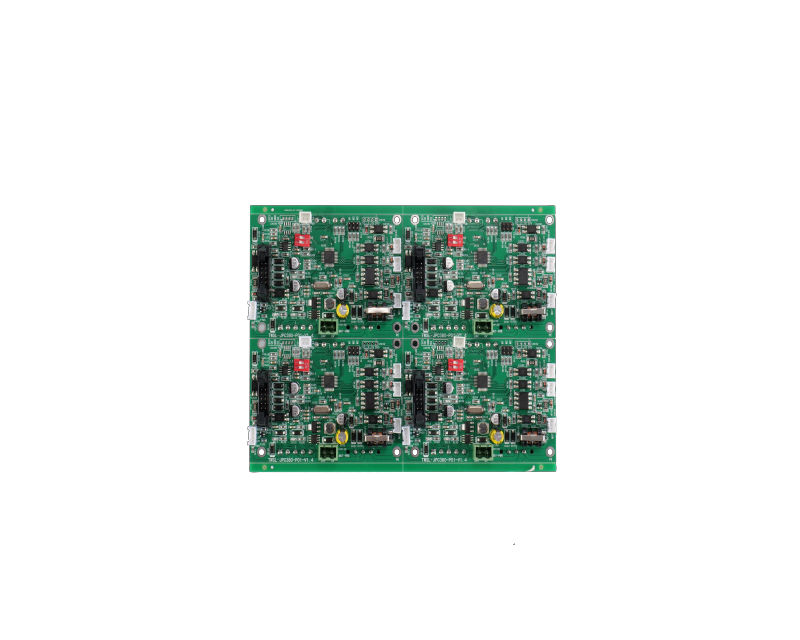

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the foundation for connecting and supporting electronic components. In today's world of cutting-edge technology, increasing signal speeds, and miniaturization, selecting the right PCB material is critical. PCB materials play a crucial role in determining the performance, reliability, and durability of these boards. These are essential in determining the electrical and mechanical properties of the printed circuit board. PCB materials affect signal integrity, thermal performance, and board durability. By understanding the different types of materials and their properties, you can make informed decisions when selecting materials for your PCB design and manufacturing process.

PCB Material Basics

What are PCB Materials?

PCB materials are the substances used to constitute the layers of a printed circuit board. These materials provide the foundation for the electrical and mechanical properties of the board, ensuring its proper function and durability. PCB materials are broadly classified into four categories: substrate materials, conductive materials, dielectric materials, and solder mask materials.

Substrate materials form the core of the PCB, providing mechanical support and rigidity. A common substrate material is FR-4. This is a composite material made from woven glass fiber cloth and epoxy resin. Other substrate materials include polyimide, ceramic, and metal core, each with unique properties and applications.

Conductive materials are used to create electrical connections between components on the PCB. They form the pathways (traces), pads, vias, and other elements in the PCB to facilitate current flow. Copper is a widely used conductive material due to its excellent conductivity and ease of processing. Copper traces are typically etched onto the substrate to form the desired circuit pattern. Other conductive materials include gold, silver, tin, indium, etc.

Dielectric materials are insulating materials used to separate conductive layers in multilayer PCBs. They prevent electrical signals from interfering with each other and help maintain signal integrity. These materials also affect signal propagation speed and characteristics. Dielectric materials can also be found within the substrate, such as in FR-4, where the epoxy resin acts as a dielectric.

Solder mask material is applied to the surface of the PCB to protect the copper traces from oxidation, corrosion, and short circuits. The solder mask also helps prevent solder bridges during assembly. Common solder mask materials include liquid photoimageable (LPI) and dry film solder mask.

Functions of PCB Materials

PCB materials serve various functions within a printed circuit board, each impacting the overall performance and reliability of the board. Some key functions of PCB materials include providing mechanical support, ensuring electrical performance, managing heat dissipation, and providing environmental protection.

Mechanical Support: Substrate materials form the core of the PCB, providing mechanical support and rigidity to the board. This support is crucial for maintaining the structural integrity of the board during assembly, handling, and operation. The choice of substrate material significantly impacts the mechanical properties of the board, such as stiffness, flexibility, and resistance to mechanical stress.

Electrical Performance: Conductive materials (e.g., copper) establish electrical connections between components on the PCB. The choice of conductive material and its thickness affect the board's electrical performance, including signal integrity, resistance, and capacitance. Dielectric materials also influence electrical performance by separating conductive layers and preventing signal interference.

Heat Dissipation: Efficient thermal management is crucial for maintaining the performance and reliability of electronic components on the PCB. The choice of PCB materials significantly impacts the board's thermal performance. Materials with high thermal conductivity (e.g., metal core materials) can help dissipate heat more effectively, reducing the risk of component failure due to overheating.

Environmental Protection: PCB materials must withstand various environmental conditions, such as temperature fluctuations, humidity, and chemical exposure. The solder mask protects copper traces from oxidation, corrosion, and short circuits, while the properties of the substrate material influence the board's resistance to moisture absorption and thermal expansion.

By understanding the functions of PCB materials and their impact on board attributes, designers can make informed decisions when selecting materials for their projects.

Previous :

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs