Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Classification of PCB materials

PCBs still use traditional materials such as copper, aluminum, and iron. These materials allow for the integration of components using surface mount technology (SMT). They also offer mechanical durability. Therefore, metal-based PCBs have a longer product lifespan.

Today, PCBs are used in almost all types of electronic devices. From satellites to watches, we use PCBs. It reduces the size of the device, making it more compact, as large circuits can be embedded on a small PCB. All small, precision components can be easily placed on it. Besides providing conductivity, it also provides a mechanical support base for the components. Today, the use of PCBs is very common, and the performance of a project depends on the PCB material you use. Therefore, if the PCB is perfect, your project will run perfectly. Cheap PCBs cannot accurately provide the desired results.

To reduce the risk of project failure due to PCB materials, you need to carefully select PCB materials. You need to discuss your requirements with the PCB manufacturer or fabricator. You should understand the characteristics of different PCB materials.

1. What are PCB materials?

Simply put, a PCB is a physical board that provides conductive paths for components and electrically connects them. It is an essential circuit board for devices and electrical appliances. It is also a necessary carrier for software functions. Different devices have different PCB materials, different circuit boards, and different components. PCBs are made of special materials, which are important in PCB manufacturing. Different insulating materials are used to make PCB layers. This layer serves as a base for placing electrical/electronic components. To make excellent PCBs, you need to choose the right PCB materials. Therefore, PCB materials play an important role in determining its quality.

2. Classification of PCB materials

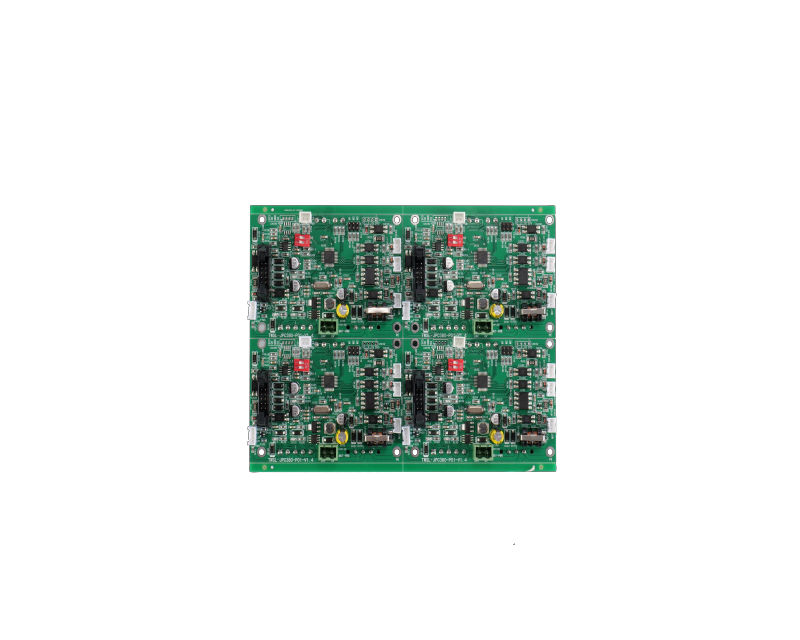

Generally, PCB board materials can be divided into two categories: rigid substrate materials and flexible substrate materials.

a) Rigid Printed Circuit Board (Rigid PCB or RPCB)

The general rigid substrate material for rigid PCBs is copper-clad laminate (CCL), which is made of reinforcing materials. The preparation of copper-clad laminates involves several steps: first drying, then cutting to the required size and shape, and then pressing the parts into blanks. At this stage, the PCB is a pure insulator without conductive paths. Copper foil is then placed on it and formed under high temperature and pressure. Pure copper is used because of its high conductivity and good solderability. The commonly used thickness is 35-50/ma. The commonly used thicknesses of copper-clad laminates are 1.0mm, 1.5mm, and 2.0mm.

b) Common flexible PCB materials

You cannot install flat PCBs everywhere, as not all devices are flat. Their shapes and designs are irregular. Therefore, flexible PCBs are needed. In recent years, flexible PCBs have been in high demand due to their applications. They can be easily folded and bent, so you can install them on various devices. They can be bent, but they can effortlessly transmit current throughout the PCB. Their bending properties do not affect conductivity. They are excellent and are widely used today.

Common flexible PCB materials include polyester film, polyimide film, and fluorinated ethylene propylene film.

2.1 Types of materials used in PCB manufacturing

There are three main types of materials used in the manufacture of PCBs:

FR-4

This is a commonly used material in PCBs. It is a glass-reinforced epoxy laminate. The epoxy resin used has flame-retardant and waterproof properties. It has an excellent strength-to-weight ratio. This material has very high tensile strength.

PTFE (Teflon)

PTFE is a plastic material that does not offer any resistance. Therefore, it can be used in high-speed, high-frequency applications. PTFE is very flexible and is useful in applications with tight tolerances. It is also very lightweight and can be used in various industries. It is also flame-retardant, has high physical strength, temperature stability, and is versatile.

Metal

PCBs still use traditional materials such as copper, aluminum, and iron. These materials allow the use of surface mount technology (SMT) to integrate components. They also provide mechanical durability. Therefore, metal-based PCBs have a longer product life.

Typical PCB products using metal include: copper-clad PCBs, aluminum PCBs, LED PCBs, and metal core PCBs.

Different materials used in PCB design and manufacturing have their own advantages and disadvantages. When choosing materials, the application, desired results, environmental factors, and any other limitations the PCB will face should be considered. You should choose PCB materials based on the expected results.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs