Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What is semiconductor load board PCB testing?

Semiconductor load board PCB evaluation involves collecting different measurement data to compile historical test data. The application of semiconductor load board PCB testing allows the creation of baseline measurements, which enables more accurate measurement of data related to IC performance integrity assessment.

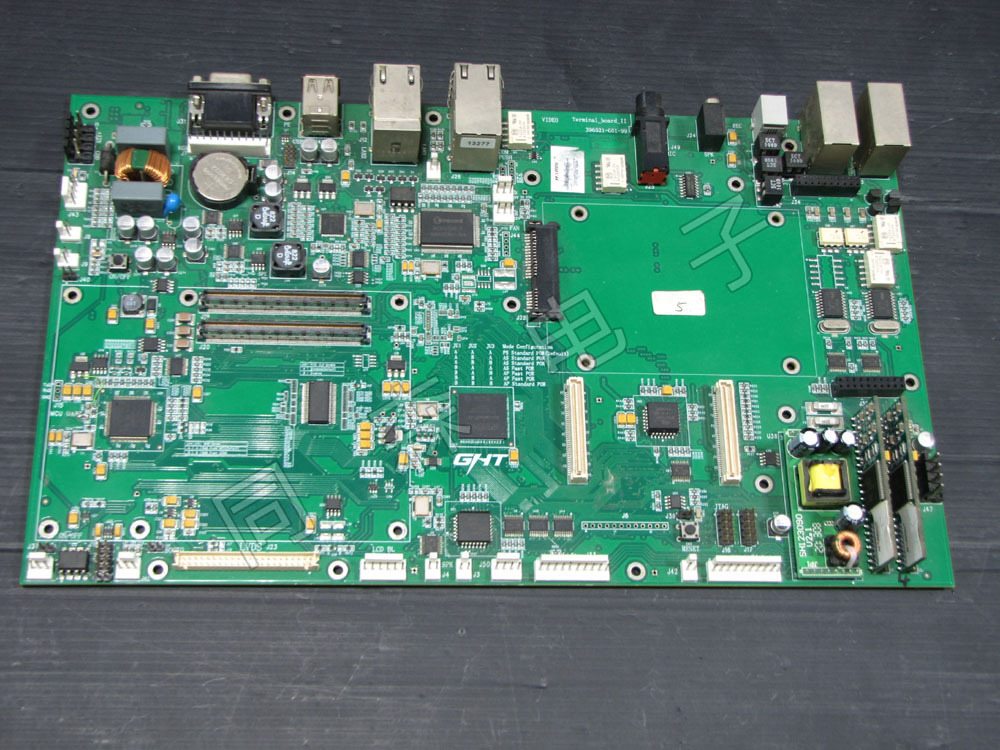

Semiconductor load board printed circuit boards (PCBs) are used in the manufacturing process of integrated circuit (IC) units. Semiconductor load board PCBs are used to test packaged ICs.

Load boards consist of a PCB containing test sockets. The board is mounted on a test head. The semiconductor load board structure must be free of defects as it will affect the results of the IC unit.

Semiconductor Load Board PCB Testing: An Overview

A semiconductor load board PCB is the interface between the pins of the unit under test and the semiconductor test equipment.

Load boards are used to verify that the component being tested is free of defects. Testers must assess whether the test board accurately captures defects in the component being tested.

Semiconductor load board PCBs must be inspected before production testing. The performance of the semiconductor load board PCB must be verified before the production test run in the field. The equipment must be tested regularly to ensure that it can detect end-of-life failures of the board.

Features of Semiconductor Load Board PCB Testing

Semiconductor load board PCB testing methods allow for complete and fixtureless testing of the load board. Most professional semiconductor load board PCB testing involves testing large load boards. The testing methods performed by professional semiconductor load board PCB testers help identify defects in the process.

Semiconductor load board PCB evaluation methods can determine problems such as shorted and open pins. Professionals performing semiconductor load board PCB testing can pinpoint weak components. Semiconductor load board PCB evaluation methods can help address problems with components such as relays.

Through professional semiconductor load board PCB evaluation, technicians can understand problems with the IC board within hours. Semiconductor load board PCB testing does not involve application-specific tools.

When to Use Semiconductor Load Board PCB Testing Equipment?

Semiconductor load board PCBs are designed to test equipment according to a test plan. Distortion must be minimized for accurate analysis of equipment performance. In addition, the load board PCB must be flexible to easily handle future testing needs.

Meeting the goals of load board testing equipment often requires some trade-offs. How testing is performed and examples of trade-offs are as follows.

Suppose the semiconductor load board PCB test plan is to drive a clock to the IC device under test (DUT). You must first route the tester clock source to the clock pin of the DUT. The clock pin of the DUT must be connected to the socket on the semiconductor load board PCB.

To minimize distortion, you must keep the clock length connected to the DUT as short as possible. The clock pin should not be hardwired to the clock source, as this will prevent you from using higher-performance clocks for advanced testing.

The cost of achieving the flexibility goal of the semiconductor load board PCB is that some accuracy must be sacrificed. The required cables and connectors may degrade the quality of the clock signal, which must be considered when using a semiconductor load board PCB.

Benefits of Semiconductor Load Board PCB Testing

As semiconductor designs become more complex, verifying the integrity of ICs becomes increasingly difficult. Semiconductor load board PCB testing allows manufacturers to test IC units containing billions of circuits in a tiny area.

With semiconductor load board PCB testing, manufacturers can more accurately verify the performance of complex IC designs. Here are some benefits for IC device manufacturers using semiconductor load board PCBs.

Saving Continuity Testing Time

Verifying the continuity of load board performance using semiconductor load board PCB testing will help save costs and time.

The actual cost of verifying IC performance using standard test equipment can reach thousands of dollars annually. Companies must bear the cost of regular performance testing to measure the performance of ICs over their lifecycle.

Using semiconductor load board PCB testing can significantly reduce the cost and time of board verification compared to verification using standard test equipment worth millions of dollars.

Verification of Different Load Board Performance

Dedicated semiconductor load board PCBs can be used to verify the performance of load board configurations with different measurement capabilities.

Semiconductor load board PCBs are mechanical and electrical connectors between the test equipment and the IC. Using semiconductor load board PCBs, manufacturers can reliably verify the integrity and performance of integrated circuits.

Data Accuracy Verification

Semiconductor load board PCBs will enable accurate testing of measurement data. Assessing short-circuit or open-circuit performance between contacts using an ohmmeter may be less expensive. However, manual measurements cannot accurately assess IC performance.

For modern ICs with hundreds and thousands of pins, manual methods are not practical. Semiconductor load board PCB testing will provide accurate performance testing for advanced IC designs.

Advanced Performance Measurement

Semiconductor load boards PCBs offer advantages over standard ATE testing in terms of resistance and leakage current testing. The testing method involves verifying the IC unit to ensure that there are no short circuits or open circuits in the internal circuits.

Manufacturers can use semiconductor load board PCBs to understand leakage current and circuit resistance. Manufacturers can use it to understand the capacitance of the unit and evaluate it against standards.

The resistance current range tested generally ranges from 1mW to 100mW. The accuracy of semiconductor load board PCB testing is 0.1%.

Using semiconductor load board PCBs, manufacturers can also understand device resistance in the range of 10 nA to 100 μA with an accuracy of 1%. In addition, the capacitance of the device can be tested in the range of 10 pF to 10 mF with an accuracy of 5%.

Load board resistance is typically less than 100 mW, and leakage current is less than 100 nA. The capacitance value depends on the value and number of capacitors on the board. The cost of verifying test integrity is between $350 and $500 per hour.

Complex System Testing

The semiconductor load board PCB method also involves verification of diode performance. Test objects include Zener diodes, rectifier diodes, and transient diodes. In addition, system testing can be performed for user-specified relay armature voltages and high-voltage components up to 35V in IC circuits.

Through semiconductor load board PCB evaluation, manufacturers can understand propagation and impedance delays. Testing is performed using a time domain reflectometer during the circuit board design process.

Flexible Board Testing

Semiconductor load board PCB testing offers flexibility in testing IC integrity and reliability. Manufacturers can evaluate test heads by simulating different test heads. This method allows for cost-effective verification of circuit performance. It allows testing of IC integrity for different ATE models.

The versatility and ease of use of the test help save time and cost in measuring circuit integrity. It is more versatile and cost-effective than using dedicated test systems located at the manufacturer's factory.

Manufacturers can engage companies that provide semiconductor load board PCBs to check the integrity of manufactured circuits without investing in expensive systems.

Different Testing Options

Semiconductor load board PCB testing offers flexibility in testing devices. It involves point-to-point resistance testing between different contact points on the PCB. This method allows for proper verification of socket-to-PCB termination.

One method used in semiconductor load board PCB testing is to place a shorted device into the socket and check continuity by testing the resistance of the parallel return path. Integrity can be checked using a custom device simulator via the daisy chain resistance method.

Evaluation After Assembly

Semiconductor load board PCBs enable testing of new circuit boards immediately after assembly. Semiconductor load board PCB evaluation performed by skilled technicians allows for accurate diagnosis and precise probing.

One important method involved in the semiconductor load board PCB method is testing the spring contacts used in the sockets. Testing involves evaluating them using a contact resistance fixture before connecting the SMT interface to the load board.

Semiconductor load board PCBs can measure the integrity of a circuit board. Technicians performing advanced semiconductor load board PCB testing can provide value during manufacturing. Semiconductor load board PCB evaluation can detect faulty load boards. With semiconductor load boards, manufacturers can test the integrity of components after assembly.

Manufacturers can test new loads with semiconductor load board PCBs. Weak components can be identified using semiconductor load board PCB evaluation methods.

Key Test Parameters

Contact resistance fixtures can identify and replace faulty spring contacts. Semiconductor load board PCB testing enables companies to check system integrity using integrated hardware and software systems for load verification and testing.

Advanced semiconductor load board PCB testing allows understanding the range, type, and tolerances of the DUT to evaluate key parameters. Semiconductor load board PCB evaluation can be customized to ensure more accurate measurements.

Semiconductor load board PCB testing also allows jumping from one test to another without loss of measurement accuracy. The purpose of semiconductor load board PCB testing is to quickly and easily transition from one simulation to another.

Semiconductor load board PCB testing accounts for characteristic capacitance, leakage, and resistance that may lead to erroneous measurements. Advanced semiconductor load board PCB evaluation focuses on the accuracy of measurements to ensure compliance with key success parameters.

Baseline Measurements Using Semiconductor Load Board PCB Testing

Semiconductor load board PCB evaluation involves collecting different measurement data to compile historical test data. The application of semiconductor load board PCB testing allows the creation of baseline measurements, which allows for more accurate measurement of data related to IC performance integrity evaluation.

Manufacturers can use data from semiconductor load board PCB testing to create benchmarks to use as a basis for future performance evaluations. Semiconductor load board PCB evaluation involves using test measurements to determine operational trends and maintenance schedules.

Summary

Semiconductor load board PCB testing does not require investment in advanced hardware and software. Experienced technicians can perform semiconductor load board PCB testing and generate results in a short time. Semiconductor load board PCBs are performed using CAD data extracted from the load board.

All procedures involved in semiconductor load board PCB testing can be completed within a day. The system involved in semiconductor load board PCB evaluation helps identify problems and defects. Semiconductor load board PCB testing is a starting point for more advanced testing.

Previous :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs