Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What does PCB mean? PCB overview and design

Whether you are an electronics engineer, student, or electronics researcher, you will need to deal with PCBs and related products every day, such as PCB layout, components, and product R&D. Therefore, understanding the meaning of PCB is one of the most basic things for you.

What does PCB stand for?

PCB is an abbreviation with multiple meanings. What does PCB mean in the electronics field? In electronics, PCB stands for Printed Circuit Board, the main board that supports and connects electronic components.

Whether you are an electronics engineer, student, or researcher, you will need to deal with PCBs and related products every day, such as PCB layout, components, and product R&D. Therefore, understanding the meaning of PCB is one of the most basic things for you.

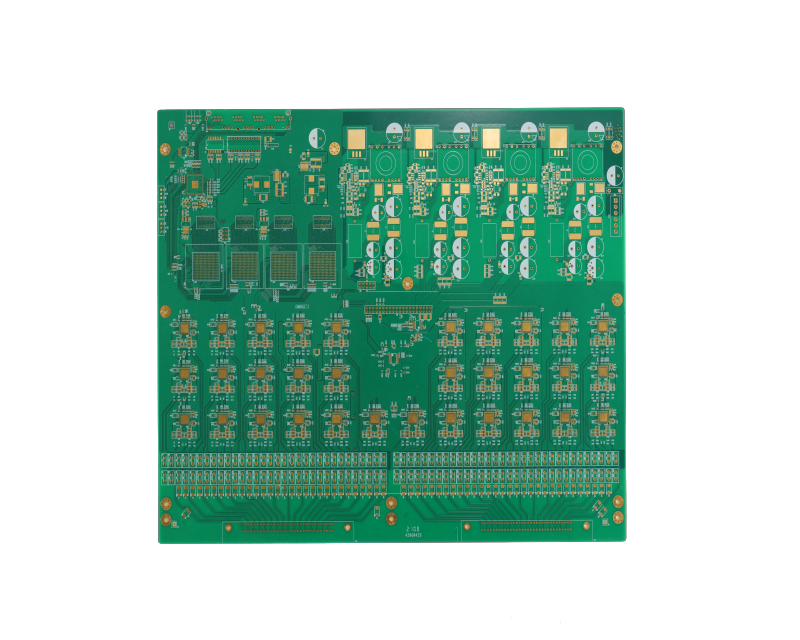

Essentially, a PCB is a system of conductive patterns located within and on the surface of a dielectric substrate, interconnected via a circuit diagram.

Many types of PCBs have significant differences. However, a normal PCB structure includes a substrate, alternating layers of prepreg and copper lines, copper pads on the surface, copper vias connecting different PCB layers, and a solder mask.

In a PCB, copper vias connect copper lines on different layers, while PCB pads on the surface of the dielectric substrate are designed for soldering electronic components. In this manageable way, various components can be integrated and connected on a small PCB board.

Now you should understand what PCB stands for in the electronics field. As a carrier for electronic components and providing electrical connections, the PCB is a fundamental and crucial component of all modern electronic devices and systems.

With the advent and gradual development of PCBs, the size of electronic products has become smaller and smaller (imagine that earlier computers were only as large as a classroom, while today's microcomputers are only as large as a palm), while the electrical functions of electronic devices have become more and more numerous.

How do PCBs promote the advancement of electronic products? See the functions of PCBs below.

PCB Functions

Circuit boards are used for the electrical connection and mechanical fixation of quantum electronics and electronic components (passive and active electronic components mounted on them).

The role of a PCB is to support electronic components and ensure the electrical connections required for system operation. PCBs cannot perform these functions alone; soldering is required to establish the mechanical and electrical connections between components and circuit tracks.

The functions of a PCB include:

Mechanical Support: All PCBs can mount electronic components and provide mechanical support for them. Rigid PCBs have good mechanical strength and serve as the supporting frame for electronic devices.

Electrical Connection: PCBs establish electrical connections for components by providing a network of copper lines. These lines transmit power and signals between different parts of the circuit to achieve communication and functionality.

Heat Dissipation: PCBs play an important role in heat dissipation, protecting components and circuits from overheating. PCBs can not only mount heat sinks for heat dissipation, but the PCBs themselves can also dissipate heat, especially ceramic PCBs and MCPCBs.

Miniaturization of Device Size and Weight: The use of PCBs allows various components to be integrated onto a very small circuit board, saving space and weight in electronic products. Using micro-vias and multilayer circuits can make the product even smaller.

Flexibility: By using flexible PCB materials such as polyimide (PI) or polyester (PET), flexible PCBs can be bent, stretched, and shrunk to fit tight spaces. In addition, using flexible PCBs can save connectors. They are thin, further reducing product size.

Improved RF Signal Transmission and Reception: In a PCB, copper lines carry signals and are responsible for signal transmission, but for high-speed, high-frequency circuits, the PCB material is crucial, and its role includes improving the reception and transmission of radio frequency (RF) signals. High-frequency PCBs using PTFE material have good dielectric properties, a small coefficient of expansion and contraction, and are beneficial for RF signal distribution.

From calculators and microwave ovens to mobile phones and aircraft control systems, all electronic devices used today involve the use of PCBs. The purpose of a printed circuit board is to connect electrical components in an organized way in a simplified manner.

For successful PCB functionality, the circuit must work, and you need to ensure that you are working with a reliable PCB manufacturer.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs