Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What is the main business of an SMT surface mount technology processing plant?

SMT surface mount technology (SMT) is a crucial technology in electronics manufacturing, encompassing processes such as PCB board production, component pressing, reflow, testing, and packaging. It can also provide value-added services such as PCB design, component procurement, testing, and repair.

Surface Mount Technology (SMT) assembly is a crucial technology in electronics manufacturing, encompassing processes such as PCB production, component mounting, reflow soldering, testing, and packaging. It can also provide value-added services such as PCB design, component sourcing, testing, and repair.

PCB Board Fabrication: Based on customer-provided circuit diagrams, the factory first produces the PCB board, which forms the foundation of the entire SMT assembly process.

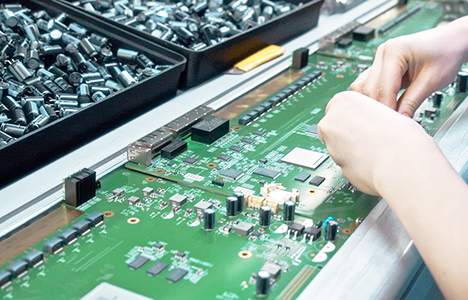

Component Placement: Next, the factory uses advanced placement machines to automatically and precisely mount electronic components onto the PCB. The accuracy and efficiency of this step directly determine product quality and production efficiency.

Reflow Soldering: The mounted electronic components undergo reflow soldering to ensure a strong and reliable bond between the components and the PCB.

Inspection: After soldering, the factory performs rigorous inspections of the PCB to ensure it meets customer requirements and standards. This includes electrical performance testing, visual inspection, and other stages.

Packaging: Inspected products are carefully packaged and prepared for shipment to the customer.

In addition to the SMT assembly processes mentioned above, many factories offer a range of value-added services to meet diverse customer needs. These services include:

PCB Design: Based on customer requirements, the factory can provide professional PCB design services to ensure the rationality and efficiency of the circuit design.

Component Sourcing: For customer convenience, factories typically offer component sourcing services, ensuring the reliability and stable performance of the components used.

Testing and Repair: After SMT assembly, the factory provides comprehensive testing services to ensure product quality. Simultaneously, the factory also provides timely repair services for any potential issues.

The global SMT PCBA market is projected to grow at a compound annual growth rate of 8%. Surface mount technology offers many advantages, making it a good choice for PCBA manufacturing. Let's explore the main advantages in more detail.

1. Faster Assembly Time

One of the biggest advantages of surface mount technology is that it is much faster to assemble than through-hole mounting. This is because there is no need to insert leads into through-holes and then solder them in place. Instead, all components are placed on the surface of the PCB and soldered at once.

This not only saves time but also reduces the possibility of human error. Furthermore, it allows for automation, further speeding up the process. In fact, automated SMT machines can place up to 30,000 components per hour!

2. Smaller Component Size

Another significant advantage of surface mount technology is that it opens the door to smaller component sizes. Compared to THT technology, the size can be reduced by 4 times – a significant reduction considering the current trend of miniaturization in products.

Smaller PCBA components are preferred in most applications because they occupy less space and are less likely to be damaged. This is especially true for handheld devices, where space is often at a premium.

3. Higher Density

The reduction in the size of surface mount components also allows for higher density on the PCB. This is because more components can be placed closer together. This is a great advantage because it allows more functionality to be packed into smaller devices.

Since surface mount components are placed directly on the surface of the PCB, through-holes are also unnecessary. This further increases the available space on the board, allowing for higher component density. It can also reduce the weight of the PCBA – by up to 10% in most cases.

4. Higher Accuracy

Another benefit of surface mount technology is its ability to improve the accuracy of component placement: components are placed on the PCB using automated machines. This means there is less chance of human error, which can lead to incorrectly placed or misaligned components.

Furthermore, most SMT assembly lines use vision systems to check the placement of each component. This double-check further reduces the possibility of errors and ensures that each board meets the required specifications.

5. Improved Performance

Surface mount technology also has the potential to improve the performance of the PCB. Why? With SMT, the lead lengths between components are shorter. Shorter lead lengths reduce inductance, which improves high-frequency performance.

Furthermore, because there are no through-holes, PCB traces can be routed more directly between components. This can also reduce inductance or RF interference, thus improving performance.

6. Greater Flexibility

Another major advantage of surface mount technology is that it offers greater flexibility in design. This is because there is no need to consider leads, nor is there a need to drill through-holes. This allows you to experiment more freely with the layout of the PCB.

Furthermore, SMT components can be placed on both sides of the board. This further enhances design flexibility and allows for higher density, in addition to opening up new possibilities for routing.

7. Cost-Effectiveness

It is worth mentioning that surface mount technology is generally more cost-effective than through-hole mounting. Surface mount technology is faster and easier to assemble when using automated equipment, thus reducing labor costs.

The smaller size of SMT components also makes them less expensive to produce. Since both sides of the PCB can be used, the overall size of the board can also be reduced, saving on material costs. Overall, using SMT technology can reduce costs by up to 30%.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs