Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Understanding the steps and types of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) refers to the surface mount process, a technology used in electronics manufacturing to solder components onto printed circuit boards (PCBs). In through-hole surface mount technology, components with leads inserted into holes in the circuit board are used, while SMT components are placed directly onto the surface of the circuit board, saving space and increasing packaging density.

Surface Mount Technology (SMT) refers to the surface mount process, a technique used in electronics manufacturing to solder components onto printed circuit boards (PCBs). In contrast to through-hole surface mount technology, which uses components with leads inserted into holes in the circuit board, SMT components are placed directly onto the surface of the board, saving space and increasing packaging density.

Compared to components used in through-hole technology, SMT components are typically smaller and lighter, allowing manufacturers to produce more compact and lightweight devices. SMU linear circuits consist of smaller components such as resistors, capacitors, diodes, integrated circuit packages, and many electronic components.

The surface mount technology process involves several steps:

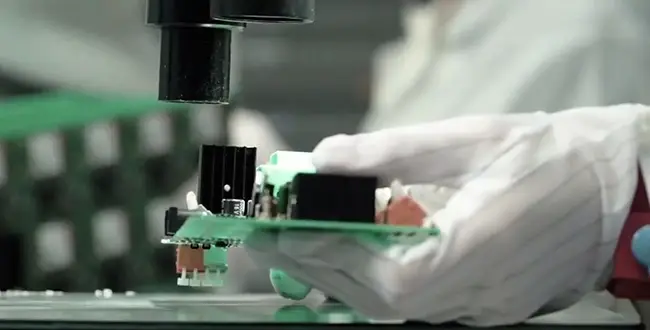

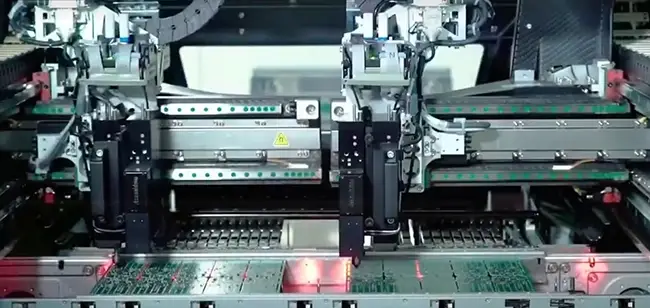

Component Placement:

Automated machines pick up SMT devices from reels and trays and then accurately place them onto the designed pattern.

Solder Paste Application:

Solder paste, a viscous liquid containing flux and small-sized solder balls, is applied to the PCB pads where these components will be placed.

Reflow Soldering:

The PCB containing the reflow soldered components, SMCs, and pads is then passed through a reflow oven. In this oven, molten solder is used to pull the components to form solder joints, providing a strong electrical and mechanical connection between the components and the board.

Inspection:

The solder is then placed on the PCB, and the PCB is inspected to determine if all components have been correctly placed and soldered. This may include automated visual inspection, automated optical inspection (AOI), or X-ray inspection.

Testing:

Once the PCB assembly is complete, it can be checked to ensure that it functions correctly.

SMT has become the dominant method for producing electronic products due to its speed, accuracy, and cost-effectiveness. It brings computerized automation processes, reducing manufacturing time and producing more complex electronic circuit devices.

What are the types of surface mount components?

Surface mount components (SMCs) are electronic components designed as surface mount devices, directly mounted onto the surface of a printed circuit board (PCB), unlike through-hole components that are inserted into holes drilled on the PCB. Surface Mount Technology (SMT) allows SMCs (chip circuit devices) to be mounted onto the surface of a PCB. In contrast, through-hole technology requires drilling holes on the PCB to insert them, while SMT does not require drilling. There are different types of surface mount components in surface mount technology, each with its specific use in various electronic circuits. Here are some common types:

Surface Mount Resistors (SMD Resistors): These are surface tension resistors specifically designed for mounting on printed circuit boards. They come in various sizes and shapes, and their resistance values will be indicated by color codes or printed directly on them.

Surface Mount Capacitors (SMD Capacitors): Surface mount capacitors are capable of providing energy for storage and then releasing it back into the electronic circuit. They come in various forms, such as ceramic, tantalum, and electrolytic capacitors.

Surface Mount Inductors (SMD Inductors): This type of inductor is manufactured to be mounted on the surface of a PCB. They provide space for energy in a magnetic field and are commonly used in filters, oscillators, and power supplies.

Surface Mount Diodes: Diodes are components that allow current to flow in only one direction and are used for rectification, switching, and signal demodulation in various circuits. Surface mount diodes are designed to be directly mounted onto PCB components.

Surface Mount Transistors (SMD Transistors): Transistors are semiconductor components responsible for amplifying or switching electronic signals. Surface mount transistors come in various types, from NPN to PNP to MOSFET and JFET.

Surface Mount Integrated Circuits (SMD ICs): Small outline integrated circuits (ICs) are highly advanced and compact circuits with many components mounted on a single chip. Commonly, surface mount ICs are used extensively in various electronic products, including microcontrollers, memory devices, and amplifiers.

Surface Mount LEDs (SMD LEDs): LEDs, or light-emitting diodes, are semiconductor devices that produce light energy when current passes through them. LCDs are the primary display technology for desktop computers, televisions, and tablets.

Surface Mount Switches and Connectors: These constitute some types of switches (e.g., tactile switches) and connectors, including USB connectors, HDMI connectors, that are compatible with the surface of a PCB.

These are common surface mount components in electronic devices. Different process technologies associated with surface mounting vary, each with its specific function and application. In summary, they and surface mount components are essential in all modern electronic designs because they occupy less space and are very friendly PCB manufacturing processes.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs