Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

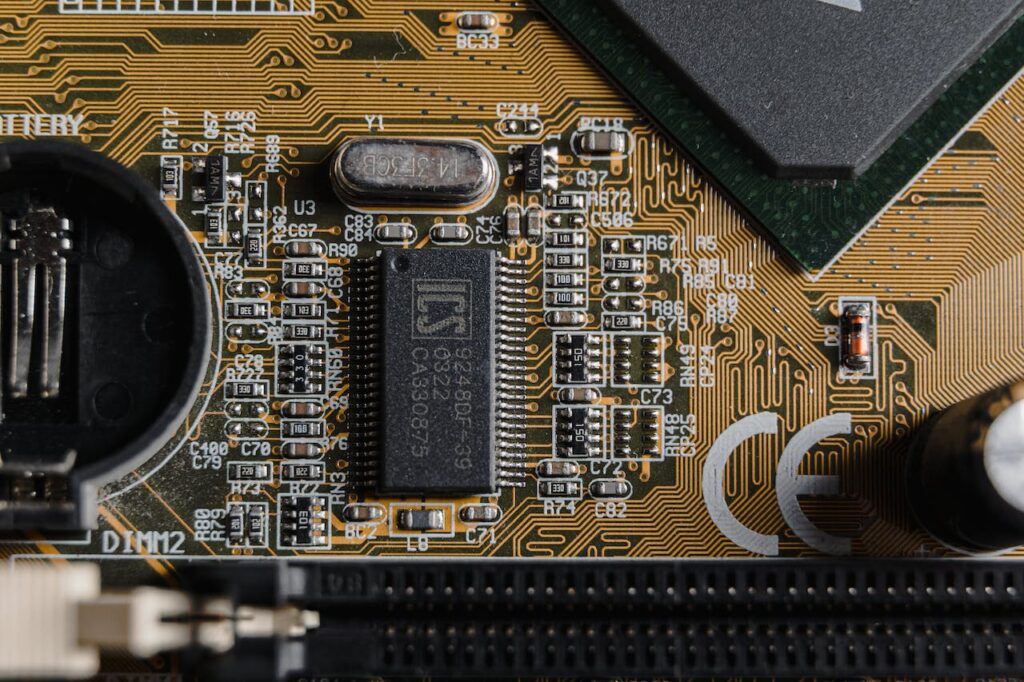

The importance of quality assurance to OEMs in PCB production

Decades of experience in electronics manufacturing have given us an in-depth understanding of QA and how it is an integral part of every stage of the manufacturing process. Let's delve into the elements of comprehensive QA and why it is so important to OEMs.

Quality assurance (QA) is critical for original equipment manufacturers (OEMs). OEMs produce components that are then sold to other companies and used by those companies in their own products. OEM components can serve many different industries, and companies rely on the quality of their products to stand out. Without the safety net provided by rigorous QA, the long-term sustainability of an OEM is not guaranteed.

Decades of experience in electronics manufacturing have given us an in-depth understanding of QA and how it is an integral part of every stage of the manufacturing process. Let's delve into the elements of comprehensive QA and why it's so important for OEMs.

Pillars of PCB Manufacturing Quality Assurance

From initial design to finished product feedback, QA plays a significant role at every stage of the production process. While multiple QA tests may be conducted at each stage, we can categorize them into several types.

Design Optimization

This stage of quality assurance involves ensuring that the PCB design is thoroughly reviewed from all angles, including elements such as component placement and signal integrity. This helps reduce the chances of problems arising during manufacturing or even later on. The materials chosen for the PCB should also be reviewed and verified before the design is approved - and the same materials should be checked again immediately before production begins to ensure they are free from defects and meet specifications.

Process Standardization

Many aspects of the manufacturing and assembly process require QA testing. This applies not only to the materials used and how they are assembled, but also to the conditions under which the PCBs are manufactured. Parameters such as temperature and speed must be regularly measured when assembling PCBs to ensure that the finished product is not only fully functional and reliable, but also consistent.

Process standardization and monitoring during construction helps reduce the likelihood of customers receiving defective products - in a way, this can be seen as solving problems before they arise. This is a good example of the difference between PCB quality assurance and PCB quality control (QC) methods - QA testing prevents errors, while QC detects and corrects errors after the fact.

Inspection and Testing

After assembly, PCBs undergo various tests to confirm that they meet the manufacturing schematic, structural quality, and durability. Automated Optical Inspection (AOI) is one of the common methods for inspecting PCBs. Images of the completed PCBs are taken using specialized cameras, and these images are then analyzed by AOI software to identify any discrepancies. AOI systems are fast, reliable, and can be integrated into production lines. They can also collect data that helps with traceability and documentation.

Continuous Improvement and Feedback

Effective QA relies on a culture of continuous improvement - using data and analytics to guide the implementation of corrective and preventive actions. Whether this data comes in the form of performance metrics or customer feedback, it is a vital component of QA that can significantly improve manufacturing efficiency and product quality.

Third-Party Quality Assurance: A Leap Towards Excellence

Outsourcing QA to a third-party service can offer many benefits.

Third-party services provide an unbiased assessment in a way that is difficult to achieve internally.

They typically have a broad understanding of industry standards and regulations, and training this knowledge into a workforce can be time-consuming.

Outsourcing QA allows OEMs to focus on their primary business objectives.

Using third-party services means benefiting from new technologies without having to bear the full cost of purchasing those tools.

Understanding the Certification Landscape

Good QA practices can help OEMs obtain various certifications needed to pass PCB manufacturing quality control checks and international standards.

Example: ISO certifications demonstrate that an OEM meets standards such as regulatory requirements and environmental responsibility. ISO 9001 is an international standard for quality management systems (QMS) that provides organizations with the framework needed to obtain certification. Some requirements depend on the control of production and operational efficiency - many of which may already be met through QA testing.

Some standards, such as IPC standards, are internationally recognized and not specific to a particular region. OEMs and any collaborating PCB manufacturers must thoroughly understand these regulations and their relationship to the final PCB product.

Best Practices for Collaboration Between OEMs and PCB Manufacturers

Any OEM seeking to collaborate with a PCB supplier should focus on these key areas to maintain their relationship and the resulting smooth operation.

Good Communication

Communication channels should be clear and well-established. This includes setting expectations early, defining timelines and specifications, and communicating immediately when changes occur.

Involvement in the Design Phase

By choosing to involve the PCB manufacturer in the early stages of their product design, OEMs can leverage their expertise to ensure that the product is cost-effective and functional. Involving them early in the process also reduces the risk of errors due to poor communication of design specifications.

Regular Progress Checks

Regular progress updates mean that if problems arise, they can be identified and addressed collaboratively. Regular meetings and working to a shared timeline will help both the OEM and the PCB manufacturer feel like a team.

Agreement on Compliance and Standards

OEMs and PCB manufacturers should agree on the standards their work must meet and reach a consensus on the QA measures that need to be followed to meet those standards.

Future Trends in PCB Manufacturing Quality Assurance

QA is constantly evolving due to a culture of continuous improvement. In manufacturing, anything that can improve efficiency is welcome, and one aspect of this evolving technology is the use of artificial intelligence. Replacing time-consuming manual processes with AI can enable "autonomous QA workflows," which will help prevent human error and employee burnout.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs