Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Difference between reflow soldering and wave soldering in PCBA processing

Advance Payment: Following industry practice, you will need to make an advance payment to the supplier. This will, of course, impact your budget, but more importantly, the likelihood of correcting quality issues is significantly reduced compared to paying the full amount upfront.

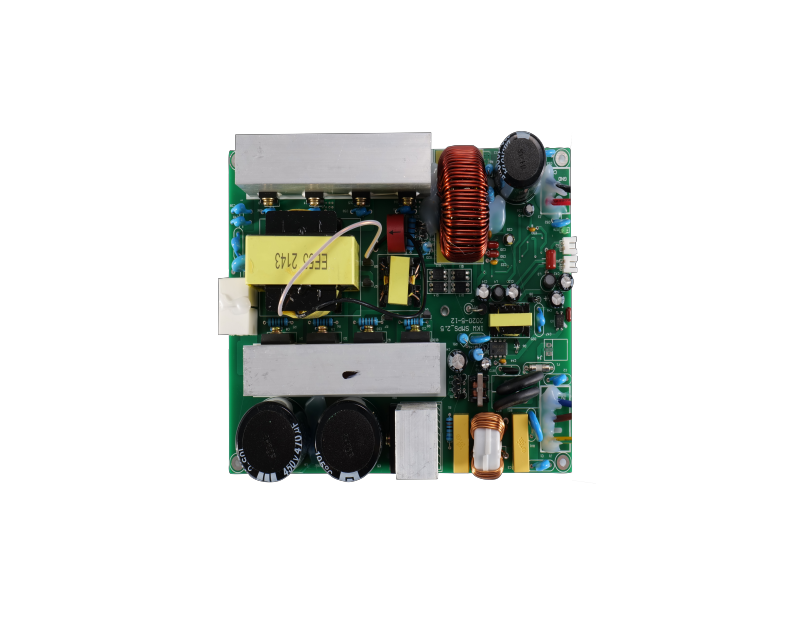

While not mandatory, most SMT surface mount components utilize reflow soldering, while through-hole components use wave soldering. In through-hole PCBA assembly technology, components are inserted into drilled holes and a strong solder joint is formed via wave soldering. Typically, through-hole components are manually inserted.

For SMT components, solder paste is applied directly to the pads, securing the component leads in place. When the PCB passes through a dedicated reflow oven, the solder paste reflows. Here, a strong solder joint is formed. If you are using a mixed type, you will need to use both wave and reflow soldering. Automated pick-and-place machines can be used to reliably handle a variety of components.

PCBA Processing: Reflow Soldering vs. Wave Soldering

Size: By default, SMT components or parts are smaller or miniature, requiring no drilling, and look clean and attractive, especially in the era of smaller electronic board sizes.

Availability: Today, SMT has largely replaced through-hole components. Their smaller size has replaced through-hole components such as resistors and capacitors, taking up an increasingly larger proportion in PCBA assembly.

Performance: Using smaller components in surface mount technology allows for shorter distances for electrical signal transmission. This also shortens signal flight time.

Cost-effectiveness: SMT parts are generally cheaper than through-hole parts. Let's quickly look at the advantages of through-hole parts.

Availability: If you need larger components for high-power applications, it may be difficult to find SMT equivalents. Through-hole components are readily available.

Strength: If a component must withstand constant stress, SMT solder joints may fracture. In such cases, components such as connectors, switches, and other interface parts require the strength effectively provided by leads soldered to drilled holes.

Power: SMT is not suitable for high-power circuits because strong solder joints are difficult to achieve with SMT soldering. Therefore, through-hole technology provides higher mechanical strength for thermal stability, high voltage, and mechanical stability.

Advantages of Choosing an SMT Processing Factory

1. PCB Quality, Reliability, and Expertise

Quality: First and foremost, the quality aspect must be considered when choosing a PCB OEM. After all, it is well known that the circuit board is the heart of an electronic device, and the quality and reliability of the final product are directly related to the quality of the PCB. When you deal with a manufacturer, you are more certain that you share a common understanding of the quality standards required to cater to the domestic market.

Expertise: PCB manufacturing is a highly technical process. What is needed is advanced industry knowledge and expertise to navigate this dynamic and ever-changing industry. Similarly, manufacturers are more likely to possess the necessary expertise because they are located in the country's earliest special economic zones and are at the forefront of technology transfer from Hong Kong and other regions. Furthermore, collaborating with other support companies on components is much easier when needed.

Reliability: A supplier's reliability stems from a multitude of factors. This could be attributed to proper communication channels, on-time product delivery, excellent customer service, and the ability to provide customized products that meet the client's unique needs. Now, all these aspects are better handled with a PCB manufacturer than any independent supplier, where you might encounter multiple issues related to delivery times, customer support (due to time zone differences), and potential communication breakdowns. Check out the guide to learn what to consider when choosing the right PCB manufacturer.

2. Disadvantages of Dealing with Mainland Suppliers

If you choose not to opt for smt processing services because of potentially lower prices, you need to keep the following points in mind. You may have to compromise on:

Shipping Costs, Quality Control, Advance Payments

Shipping Costs: While you may have negotiated the price of the PCBs, the truth is that shipping costs can throw your budget off track. You may need to spend significant time and effort that could have otherwise been spent on core business activities.

Quality Control: In fact, you have very little control over quality when dealing with inexperienced suppliers. Once the products are shipped to you and you find that they do not meet your quality requirements, there is little you can do. Furthermore, importantly, you lose valuable time, which impacts your time to market.

Advance Payments: As is industry practice, you will need to make advance payments to the supplier. Of course, this impacts your budget, but more importantly, the possibility of rectifying quality issues is significantly reduced compared to paying in full upfront.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs