Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What are printed circuit boards made of?

Adding a silkscreen layer is mainly for user convenience. It involves adding letters, numbers, and symbols to the circuit board to make it easier for users to understand the functions of different pins and LEDs.

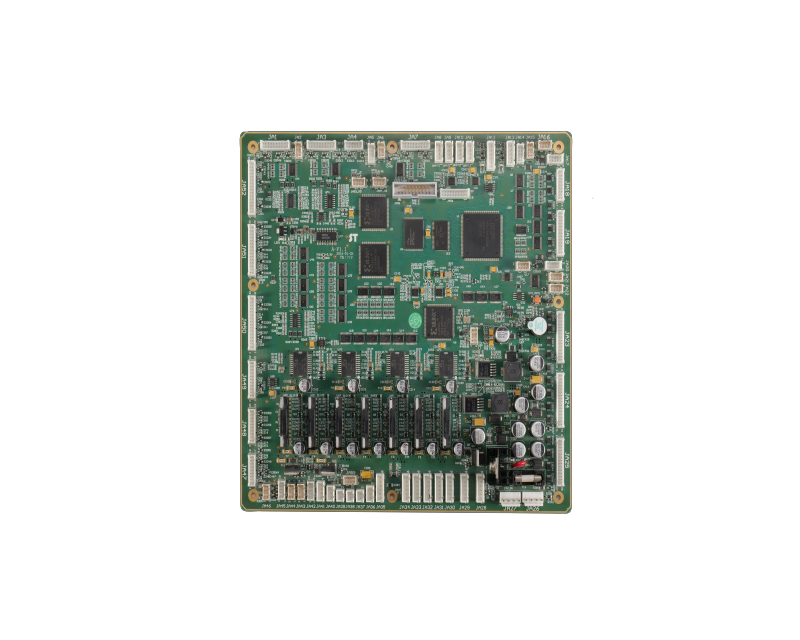

Printed Circuit Boards (also known as PCBs) are electronic boards used in most electronic devices, including phones, home appliances, and medical equipment.

Generally, PCBs are made of a non-substrate material with multiple layers of copper circuitry. However, different types of PCBs have different structures. For example, while some printed circuit boards only contain one layer of copper circuitry, more advanced PCBs may contain 50 or more layers of copper circuitry.

Generally speaking, there are several different types of PCBs. These include common options such as single-sided PCBs, double-sided PCBs, and multilayer PCBs. To help you better understand which option is right for your needs, we will discuss the different PCB materials here and how they can help you.

Common Components of Printed Circuit Boards

Printed circuit boards are made of various PCB materials and electrical components. Common PCB components include:

Resistors

Resistors transmit current to generate voltage and dissipate electrical energy as heat. Resistors are made of a variety of materials.

Capacitors

The role of a capacitor is to hold a charge within the circuit board and then release the charge when more power is needed elsewhere in the circuit. Capacitors typically work by collecting opposite charges on two conductive layers separated by an insulating material.

Inductors

Similar to capacitors, they can store energy. But they are typically used to block signals within the PCB, such as interference from other electronic devices.

Transistors

A transistor is an amplifier. It is used to switch or control electronic signals in a circuit board. There are many different versions of transistors, but bipolar transistors are common.

Transformers

They are used to transfer electrical energy from one circuit to another by increasing or decreasing voltage.

Diodes

A diode allows current to flow in one direction but not the other. Therefore, diodes are used to prevent current from flowing in the wrong direction and damaging the circuit board and equipment. A popular form of diode is the LED (Light Emitting Diode).

Sensors

These devices are used to detect changes in environmental conditions and generate electrical signals corresponding to the changes. This signal is then sent to other components on the circuit board. Sensors convert physical elements such as light movement, air quality, or sound into electrical energy.

Common PCB Layers

Each type of PCB contains a different number of layers that contribute to its functionality. However, regardless of the type of PCB you choose, every board contains the same basic foundation. This means that all PCBs contain the following four layers:

Substrate Layer

It is usually made of fiberglass, which gives the board rigidity. The substrate layer can also be made of epoxy resin, but lacks the durability provided by fiberglass.

Copper Layer

As you might expect from the name, the copper layer of a PCB is made of a thin layer of copper foil that is laminated onto the circuit board via heat.

When we talk about the different "layers" of a PCB, we are referring to how many layers of copper they are composed of. For example, a single-sided PCB only has one layer of conductive material on one side of the board. In this case, the other side of the board is used to mount different electronic components. While a double-sided PCB will have conductive copper and components mounted on both sides of the board.

The thickness of the copper layer depends on the amount of power the PCB needs to withstand. PCBs that need to withstand higher power require thicker copper layers.

Solder Mask Layer

The solder mask layer is located on top of the copper, giving most PCBs a green color. This layer insulates the copper and ensures that it does not come into contact with any other elements.

Silkscreen Layer

Adding a silkscreen layer is primarily for user convenience. It involves adding letters, numbers, and symbols to the circuit board to make it easier for users to understand the function of different pins and LEDs.

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs