Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What is a PCB board?

A carbon film printed circuit board is a printed circuit board where a conductive pattern is formed on a copper foil, and then a layer of carbon film is printed on top to form contact points or jumpers (with resistance values meeting specified requirements). Its features include simple production process, low cost, short cycle time, wear resistance, and good conductivity. It enables high density and miniaturization/lightweight design of single boards, and is suitable for televisions, telephones, VCRs, electronic keyboards, etc.

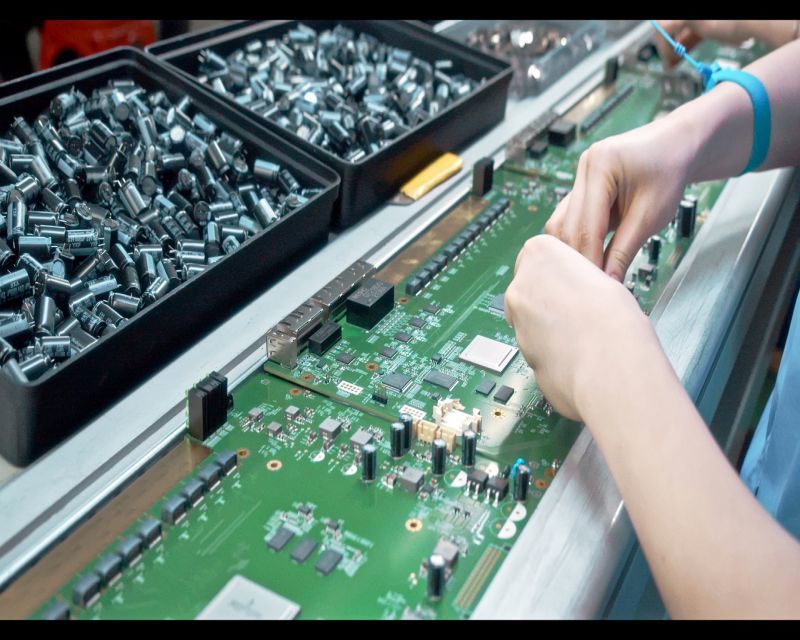

The PCB board is the mother of electronic products, also known as a printed circuit board or printed wiring board. It provides electrical connections for electronic components. It's a component that uses electronic printing technology to etch a miniature circuit network onto the surface of a non-adhesive, insulated copper-clad board, allowing various electronic components to form predetermined circuit connections and achieve relay transmission functions between electronic components. Most electronic devices and products require a PWB board.

Printed circuit boards are usually abbreviated as PWB, and some people also call them PCB substrates. Because printed circuit boards are not ordinary end products, the definition of the name is slightly confusing. For example, a personal computer's motherboard is called a motherboard, and it cannot be directly called a circuit board. Although there are circuit boards inside the motherboard, the two are not equivalent; therefore, in industry evaluations, the two are related but cannot be said to be equivalent. For example: because the circuit board carries integrated circuit components, the news media calls it an IC board, but it is not equivalent to a printed circuit board. The printed circuit board we usually refer to is a bare board—a circuit board without upper components.

According to the number of layers of the electronic board, it can be divided into single-sided, double-sided, four-layer, six-layer, and other multilayer circuit boards. It is constantly developing towards higher precision, higher density, and higher reliability. Continuously reducing the size, reducing costs, and improving performance, printed circuit boards maintain strong vitality in the future development of electronic products. The future development trend of PWB manufacturing technology is developing towards high density, high precision, small aperture, thin wires, small spacing, high reliability, multi-layering, high-speed transmission, lightweight, and thinness in terms of performance.

According to the distribution of printed circuit boards

Single-sided PCB substrate

Single-sided boards are formed by printing and etching a printed circuit on a single side of an insulating substrate with a thickness of 0.2-5mm, which is only copper-clad on one side. Single-sided boards are simple to manufacture and easy to assemble, suitable for occasions with high circuit requirements, such as radios and televisions, but not suitable for occasions with high assembly density requirements or complex circuits.

Double-sided PCB substrate

Double-sided boards have printed circuits on both sides of an insulating substrate with a thickness of 0.2-5mm. They are suitable for electronic computers, electronic instruments, meters, and other electronic products with general requirements. Because the wiring density of double-sided printed circuits is higher than that of single-sided printed circuits, the size of the equipment can be reduced.

Multilayer PCB board

A printed board with three or more printed circuits printed on an insulating substrate is called a multilayer board. It is composed of several thin single-sided or double-sided boards, and its thickness is generally 1.2-2.5mm. In order to lead out the circuits sandwiched between the insulating substrates, the holes for mounting components on the multilayer board need to be metallized, that is, a metal layer is applied to the inner surface of the small holes to connect them to the printed circuits sandwiched between the insulating substrates.

Classified by substrate properties

Rigid PCB substrate

Rigid PWB has a certain mechanical strength, and the components assembled with it are in a flat state. General electronic products use rigid printed circuit boards.

Flexible PCB substrate

Flexible printed circuit boards are made with soft layered plastics or other soft insulating materials as the substrate. Parts made with them can be bent and stretched, and can be bent arbitrarily according to installation requirements during use. Flexible printed circuit boards are generally used in special occasions. For example, the display screen of some digital multimeters can be rotated, and flexible printed circuit boards are often used inside; mobile phone displays, buttons, etc.

Rigid-flex PCB substrate

The birth and development of FPC and PWB have given rise to a new product, the rigid-flex board. Therefore, the rigid-flex board combines flexible circuit boards and rigid circuit boards through processes such as lamination, according to relevant process requirements, to form an electronic board with both FPC and PWB characteristics.

Classified by application scope

PWBs can be divided into low-frequency PCBs and high-frequency PCBs. The high-frequency of electronic equipment is a development trend, especially in today's wireless networks and satellite communications, information products are developing towards high-speed and high-frequency, and communication products are developing towards standardized high-capacity and high-speed wireless transmission of sound, images, and data. Therefore, the new generation of products requires high-frequency printed circuit boards, and foil-based boards can use materials with low dielectric loss and low dielectric constant, such as polyurethane, polyethylene, polystyrene, polytetrafluoroethylene glass cloth, etc.

Classified by special printed circuit boards

Some special printed circuit boards have emerged, such as metal core printed circuit boards, surface mount printed circuit boards, and carbon film printed circuit boards.

Metal core PCB board

Metal core circuit boards use metal plates of the same thickness to replace epoxy glass cloth boards. After special processing, the conductor circuits on both sides of the metal plate are connected to each other, and are highly insulated from the metal part. The advantages of metal core PCBs are good heat dissipation and dimensional stability. This is because magnetic materials such as aluminum and iron have a shielding effect, which can prevent mutual interference.

Surface mount printed circuit board

Surface mount printed circuit boards (SMBs) are a type of printed circuit board that has developed to meet the requirements of electronic products being light, thin, short, and small. They use surface mount device installation technology, with high pin density and low cost. Printed circuit boards have characteristics such as small hole diameter, small line width and spacing, high precision, and high requirements for substrates.

Carbon film printed circuit board

A carbon film printed circuit board is a printed circuit board in which a layer of carbon film is printed on the copper foil after the conductor pattern is formed, forming contact points or jumpers (the resistance value meets the specified requirements). Its characteristics are simple production process, low cost, short cycle, wear resistance, and good conductivity. It can achieve high density of single boards and miniaturization and lightweight of products, and is suitable for televisions, telephones, video recorders, electronic organs, etc.

Previous

Previous :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs