Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What material is the PCB made of? What is the PCB board material?

In summary, the choice of PCB material is crucial. Selecting the right material can optimize component performance, extend lifespan, and reduce costs. FR-4, PVC, PTFE, and ceramic are four common PCB materials, each with different properties suitable for various applications.

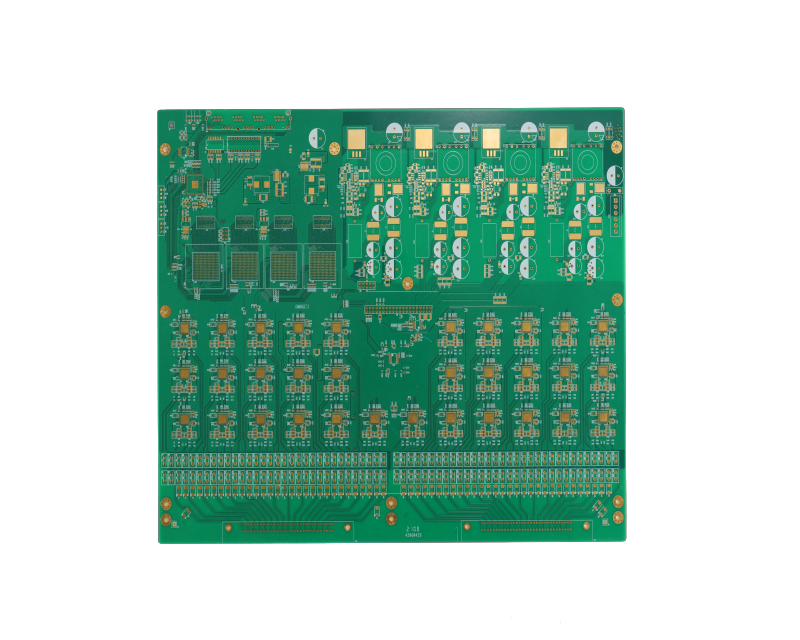

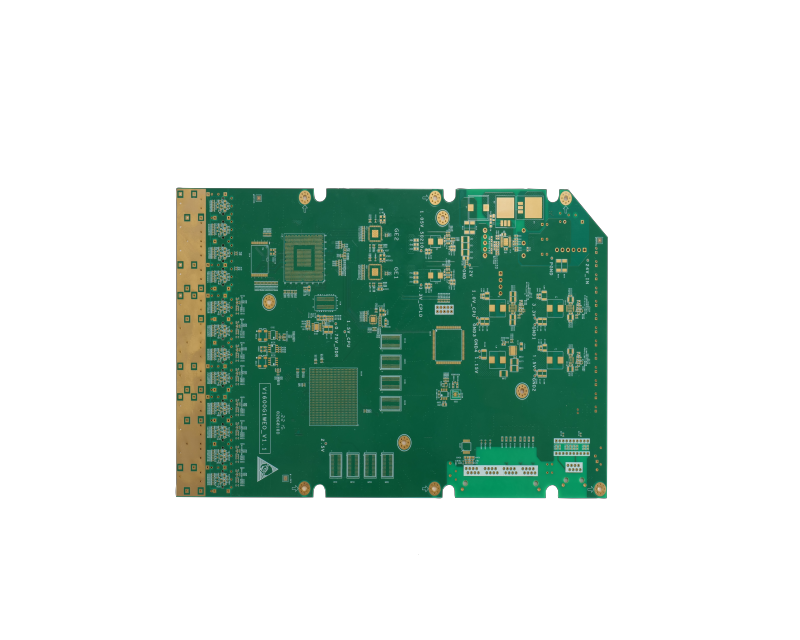

With the increasing demand for electronic components, Printed Circuit Boards (PCBs) are becoming increasingly widespread. PCBs are commonly used to connect other electronic components in various electronic devices, enabling them to communicate with each other to achieve different functions. So, what are the materials of PCBs? This article will introduce you to all the information about PCB materials.

The substrate of a PCB refers to the main material used in the PCB, which is usually an insulating material, such as fiberglass or epoxy resin. Because electronic components need to be connected to each other and are not easily interfered with or damaged, insulating materials are chosen to make the substrate. Fiberglass is one of the most widely used substrate materials because of its good physical properties, stability, and low cost.

Types of PCB Materials:

PCBs have many different materials, and the specific choice depends on the application and various requirements of the circuit board. The following materials are commonly used:

1. Fiberglass-reinforced epoxy resin (FR-4): This is one of the commonly used PCB materials, and it is used in many electronic devices. FR-4 has a fiberglass mesh, which improves the strength and durability of the PCB, making it increasingly popular in various electronic applications.

2. Polyvinyl chloride (PVC): PVC is another commonly used PCB material, which has good insulation performance and mechanical strength. Although PVC is a cost-effective material, it is not suitable for use in high-temperature environments.

3. Polytetrafluoroethylene (PTFE): PTFE is a material for high conductivity and high-frequency applications. It is often used in circuit boards that require high precision, such as high-frequency modulators and radio frequency circuits.

4. Ceramic: Ceramic is a very strong and stable material that maintains its structural stability in high-temperature environments, so it is often used in electronic devices that require high-temperature resistance.

The above four materials are commonly used PCB materials. Of course, there are other materials that can be used for PCB manufacturing, but their applications are usually very narrow.

Selection of PCB Materials:

When choosing PCB materials, the application and required characteristics of the PCB must be considered. For example, for applications requiring high strength and long life, such as automotive electronic systems and military electronic equipment, FR-4 is a good choice. For high-speed communication and high-frequency applications, PTFE material should be used.

In addition, cost factors need to be considered. FR-4 is one of the affordable materials, but PTFE is relatively expensive. Therefore, budget needs to be considered when choosing PCB materials.

Summary:

In summary, the choice of PCB material is very important. By choosing suitable materials, the performance of components can be optimized, their lifespan can be extended, and costs can be reduced. FR-4, PVC, PTFE, and ceramic are four common PCB materials, each with different characteristics suitable for different application scenarios. When we need to make a PCB, we need to carefully select the specific material and make reasonable matching according to the actual situation to achieve a good price-performance ratio.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs