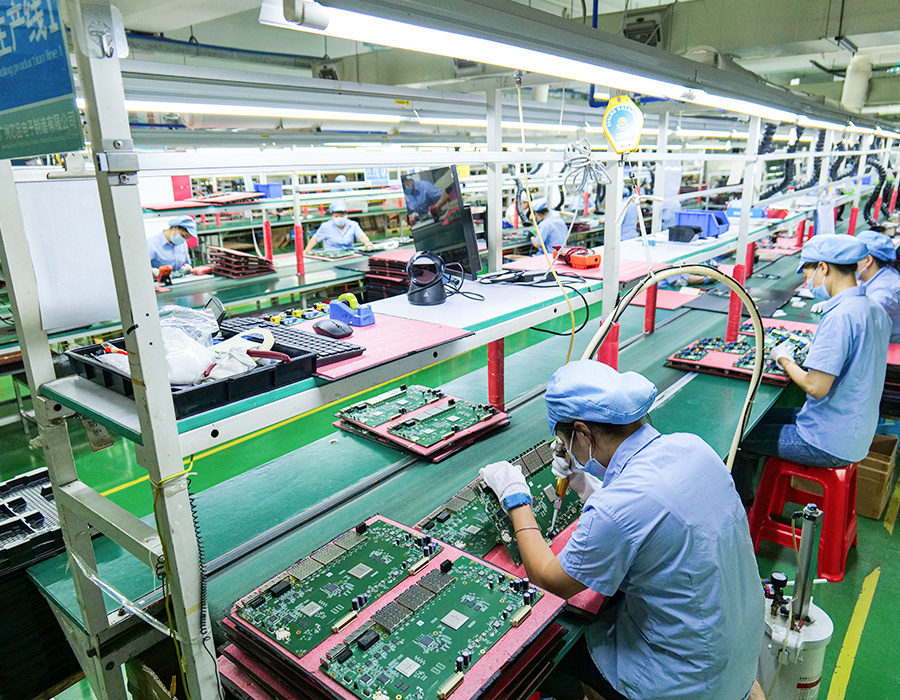

Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What is SMT (Surface Mount Technology)?

SMT (Surface Mount Technology) generally refers to an electronic assembly technology that uses automated assembly equipment to directly mount and solder miniature surface mount components (SMC/SMD, collectively referred to as chip components) to the specified positions on the surface of a printed circuit board (PCB) or other substrate.

SMT (Surface Mount Technology) is an abbreviation for a series of processes performed on a PCB. SMT is a popular technology and process in the electronics assembly industry.

SMT Concept Explanation

SMT (Surface Mount Technology) generally refers to an electronic assembly technology that uses automated assembly equipment to directly mount and solder miniature surface mount components (SMC/SMD, collectively referred to as chip components) to the specified positions on the surface of a printed circuit board (PCB) or other substrate.

In electronics industry standards, SMT (Surface Mount Technology) is called surface mount technology and is an important part of modern electronic product advanced manufacturing technology.

Generally, the electronic products we use are composed of a PCB and various capacitors, resistors, and other electronic components according to a designed circuit diagram. Therefore, electrical appliances require various SMT processing technologies for processing.

Basic SMT Process Flow

Solder paste printing -> Component placement -> Reflow soldering -> AOI optical inspection -> Repair -> Board separation.

Electronic products pursue miniaturization, and previously used through-hole components can no longer be miniaturized. Electronic products have more complete functions, and the integrated circuits (ICs) used no longer have through-hole components, especially large-scale, highly integrated ICs, which must use surface mount components. With the mass production and automation of production, factories must produce high-quality products at low cost and high output to meet customer needs and strengthen market competitiveness. It is conceivable that when the production processes of international CPU and image processing equipment manufacturers such as Intel and AMD have advanced to more than 20 nanometers, the development of SMT and other surface mounting technologies is also inevitable.

Advantages of SMT Chip Processing

High assembly density, small size, and light weight. The volume and weight of chip components are only about one-tenth of traditional plug-in components. Generally, after using SMT, the volume of electronic products can be reduced by 40%~60%, and the weight can be reduced by 60%~80%.

High reliability and strong vibration resistance.

Low solder joint defect rate.

Good high-frequency characteristics.

Reduce electromagnetic and radio frequency interference, easy to automate, and improve production efficiency.

Reduce costs by 30%~50%. Save materials, energy, equipment, manpower, and time.

SMT Process

The basic process components of SMT include screen printing (or dispensing), mounting (curing), reflow soldering, cleaning, inspection, and rework.

1. Screen printing: Its function is to print solder paste or adhesive to the PCB pads to prepare for component soldering. The equipment used is a screen printer, located at the front end of the SMT production line.

2. Dispensing: This is to drop glue to the fixed position of the PCB board. Its main function is to fix the components on the PCB board. The equipment used is a dispensing machine, located at the front end of the SMT production line or behind the testing equipment.

3. Mounting: Its function is to accurately mount surface mount components to the fixed positions on the PCB. The equipment used is a placement machine, located behind the screen printer in the SMT production line.

4. Curing: Its function is to melt the adhesive and firmly bond the surface mount components to the PCB board. The equipment used is a curing oven, located behind the placement machine in the SMT production line.

5. Reflow soldering: Its function is to melt the solder paste and firmly bond the surface mount components to the PCB board. The equipment used is a reflow soldering oven, located behind the placement machine in the SMT production line.

6. Cleaning: Its function is to remove solder residues and other harmful substances from the assembled PCB board. The equipment used is a cleaning machine, the location may not be fixed, it may be online or offline.

7. Inspection: Its function is to check the soldering quality and assembly quality of the assembled PCB board. The equipment used includes magnifying glasses, microscopes, in-circuit testers (ICT), flying probe testers, automatic optical inspection (AOI), X-ray inspection systems, and functional testers. The location can be configured at a suitable place on the production line according to the inspection needs.

8. Rework: Its function is to rework the PCB boards that cannot be detected for faults. The tools used include soldering irons, rework stations, etc., and are configured at any position on the production line.

Previous :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs