Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Introduction to Printed Circuit Boards (PCBs) and PCB Types

Over the years, PCBs have evolved from simple single-layer PCBs used in electronic products such as calculators to more complex systems, such as high-frequency Teflon designs. PCBs have entered almost every industry on Earth, from simple electronic products such as lighting solutions to more complex industries such as medical or aerospace technology.

Printed Circuit Boards (PCBs) are circuit boards used as the foundation in most electronic products - serving as both a physical support and a wiring area for surface-mount and through-hole components. PCBs are typically made from fiberglass, composite epoxy resin, or other composite materials.

There are several different types of circuit boards, each with its own specific manufacturing specifications, material types, and applications:

Single-Layer PCB

Single-layer or single-sided PCBs are made from a single layer of substrate or base material. One side of the substrate is coated with a thin layer of metal. Copper is a common coating due to its excellent conductive properties. After the copper base plating is applied, a protective solder mask is usually applied, followed by a final silkscreen to mark all the components on the board.

Because the various circuits and components of single-layer/single-sided PCBs are soldered on only one side, they are easy to design and manufacture. This popularity means they can be purchased at a low cost, especially for large orders. The low cost and high-volume nature mean they are commonly used in a variety of applications, including calculators, cameras, radios, stereo equipment, solid-state drives, printers, and power supplies.

Double-Layer PCB

Double-layer or double-sided PCBs have a thin layer of conductive metal applied to the substrate on both sides of the circuit board. Holes are drilled in the board to connect circuits on one side of the board to circuits on the other.

The circuits and components on double-layer PCBs are typically connected in one of two ways: using through-hole or using surface mount. Through-hole connections involve passing thin wires called leads through the holes, then soldering each end of the leads to the correct components.

Surface mount PCBs do not use wires as connectors. Instead, many small leads are soldered directly to the circuit board, meaning the board itself acts as the wiring surface for different components. This allows circuits to be completed using less space, freeing up space to allow the board to perform more functions, typically faster, lighter, and less bulky than through-hole circuit boards.

Double-sided PCBs are commonly used in applications requiring moderate circuit complexity, such as industrial controls, power supplies, instrumentation, HVAC systems, LED lighting, automotive dashboards, amplifiers, and vending machines. Multilayer PCBs

Multilayer PCBs consist of a series of three or more double-sided PCBs. These boards are then bonded together using special adhesives and sandwiched between insulating layers to ensure that overheating does not melt any components. Multilayer PCBs come in a variety of sizes, from as small as four layers to as large as ten or twelve layers. The largest multilayer PCB ever made was 50 layers thick.

With multilayer printed circuit boards, designers can create very thick and complex designs suitable for a variety of complex electrical tasks. Beneficial applications of multilayer PCBs include file servers, data storage, GPS technology, satellite systems, weather analysis, and medical devices.

Rigid PCBs

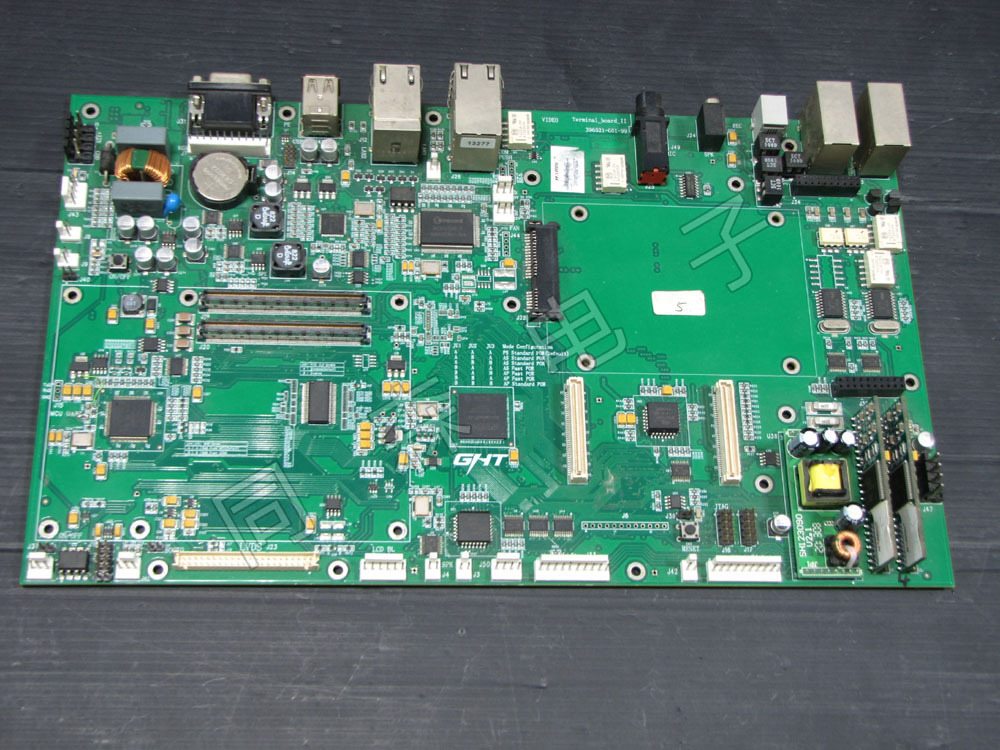

Rigid PCBs are made from a rigid substrate material that prevents the circuit board from warping. Perhaps the most common example of a rigid PCB is a computer motherboard. A motherboard is a multilayer PCB designed to distribute power from the power supply while allowing communication between all the components of the computer.

Rigid PCBs are perhaps the most numerous PCBs manufactured. These PCBs can be used anywhere that requires the PCB itself to be set to a shape and remain that shape for the remaining life of the device. Rigid PCBs can be any shape, from simple single-layer PCBs all the way up to eight-layer or ten-layer multilayer PCBs.

Flexible PCBs

Unlike rigid PCBs that use immovable materials such as fiberglass, flexible printed circuit boards are made from materials that can be bent and moved, such as plastics. Like rigid PCBs, flexible PCBs also come in single-layer, double-layer, or multilayer formats. Due to the need to print on flexible materials, flexible PCBs are more expensive to manufacture.

Nevertheless, flexible PCBs offer many advantages over rigid PCBs. Prominent among these advantages is their flexibility. This means they can be folded over edges and wrapped around corners. Their flexibility can save cost and weight, as a single flexible PCB can be used to cover areas that might require multiple rigid PCBs.

Flexible PCBs can also be used in areas that may be subject to environmental hazards. To do this, they can simply be manufactured using waterproof, shockproof, corrosion-resistant, or high-temperature oil-resistant materials - options that may not be available with traditional rigid PCBs.

Rigid-Flex PCBs

Rigid-flex circuits combine the advantages of two important types of PCB boards. Rigid-flex boards consist of multiple layers of flexible PCBs that are attached to a multilayer rigid PCB.

In some applications, rigid-flex PCBs offer many advantages compared to using only rigid or flexible PCBs. First, rigid-flex boards have fewer parts than traditional rigid or flexible boards because the wiring options of both can be combined into one board. Combining rigid and flexible boards into one rigid-flex board also allows for a more streamlined design, resulting in a smaller overall board size and package weight.

Rigid-flex PCBs are commonly used in applications where space or weight is a primary consideration, including mobile phones, digital cameras, pacemakers, and automobiles.

High-Frequency PCBs

High-frequency PCBs refer to general PCB design elements, rather than a type of PCB structure like the previous models. High-frequency PCB designs are used to transmit signals above 1 gigahertz.

High-frequency PCB materials typically include FR4 grade glass-reinforced epoxy laminates, polyphenylene ether resin, and Teflon. Teflon is one of the more expensive options currently available because of its low and stable dielectric constant, low dielectric loss, and overall low water absorption.

Many aspects need to be considered when choosing high-frequency PCBs and their corresponding types of PCB connectors, including dielectric constant (DK), dissipation, loss, and dielectric thickness.

Important among these is the dielectric constant of the material in question. Materials with a higher probability of dielectric constant variation will typically have impedance changes, which will disrupt the harmonics that make up a digital signal and lead to an overall loss of digital signal integrity - one of the design goals of high-frequency PCBs.

The following also need to be considered when choosing the type of board and PC connectors to use when designing high-frequency PCBs:

• Dielectric loss (DF) affects the quality of signal transmission. A smaller dielectric loss may result in a small amount of signal loss.

• Thermal expansion. If the materials used to manufacture the PCB (such as copper foil) have different thermal expansion rates, the materials may separate from each other due to temperature changes.

• Water absorption. Significant water absorption can affect the dielectric constant and dielectric loss of the PCB, especially when used in humid environments.

• Other resistances. The materials used to manufacture high-frequency PCBs should have high heat resistance, impact resistance, and resistance to harmful chemicals as needed.

Aluminum substrate PCB

Aluminum substrate PCBs are designed in much the same way as copper substrate PCBs. However, aluminum substrates use aluminum or copper substrates instead of the fiberglass commonly used in most PCB types.

The aluminum backing is lined with a thermal insulation material that has a lower thermal resistance, meaning less heat is transferred from the insulation material to the backing. Once the insulation layer is applied, a copper circuit layer of varying thickness from one ounce to ten ounces is applied.

Compared to PCBs with fiberglass backing, aluminum-backed PCBs have many advantages, including:

• Low cost. Aluminum is one of the abundant metals on Earth, accounting for 8.23% of the Earth's weight. Aluminum is easy to mine and inexpensive, helping to reduce costs in the manufacturing process. Therefore, the cost of manufacturing products with aluminum is lower.

• Environmentally friendly. Aluminum is non-toxic and easily recyclable. Because aluminum is easy to assemble, manufacturing printed circuit boards with aluminum is also a good way to save energy.

• Heat dissipation. Aluminum is one of the good materials currently used to dissipate heat from key components on circuit boards. Instead of dissipating heat to the rest of the circuit board, it transfers heat to the air. Aluminum PCBs cool faster than copper PCBs of the same size.

• Material durability. Aluminum is much more durable than materials such as fiberglass or ceramic, especially in drop tests. Using a stronger substrate helps reduce damage during manufacturing, transportation, and installation.

All these advantages make aluminum PCBs a good choice for applications that require high power output within very tight tolerances, including traffic lights, automotive lighting, power supplies, motor controllers, and high-current circuits.

In addition to the main uses mentioned above, aluminum substrate PCBs can also be used in applications requiring high mechanical stability or where the PCB may be subjected to high mechanical stress. Compared to fiberglass substrates, aluminum substrates are less affected by thermal expansion, meaning that other materials on the substrate are less likely to peel off, further extending the life of the product.

Over the years, PCBs have evolved from simple single-layer PCBs used in electronic products such as calculators to more complex systems such as high-frequency Teflon designs. PCBs have entered almost every industry on Earth, from simple electronic products such as lighting solutions to more complex industries such as medical or aerospace technology.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs