Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

PCBA Testing - Common Methods and Detection Techniques

PCBA testing can reveal various defects, including incorrect components, faulty solder joints, assembly problems, missing or improperly installed components, poor wire connections, and corrosion.

Why is PCBA testing and inspection necessary?

Testing and inspecting the PCBA is a necessary procedure to ensure the final product is of high quality. After the PCB assembly is completed, it will undergo testing to ensure it functions correctly. Extensive testing and inspection of the PCB assembly must be done before mass production begins. This avoids costly repairs or product recalls.

Types of PCBA Testing

Types of PCBA testing include functional testing, electrical performance testing, temperature cycle testing, shock and vibration testing, ESD (electrostatic discharge) testing, and visual inspection.

Functional testing is used to ensure that the board operates as expected once powered on.

The electrical attributes of the board (such as its current and voltage levels) are assessed through a test called "electrical performance testing".

Temperature cycle testing is used to verify that the board can withstand environmental stresses of temperature changes.

Shock and vibration testing is used to verify that the board can withstand environmental stresses of shock and vibration.

How to Test a PCBA Board?

Different methods are used to check for any defects that may be present on the PCBA board, including flying probe testing, automated optical inspection, visual inspection, and in-circuit testing.

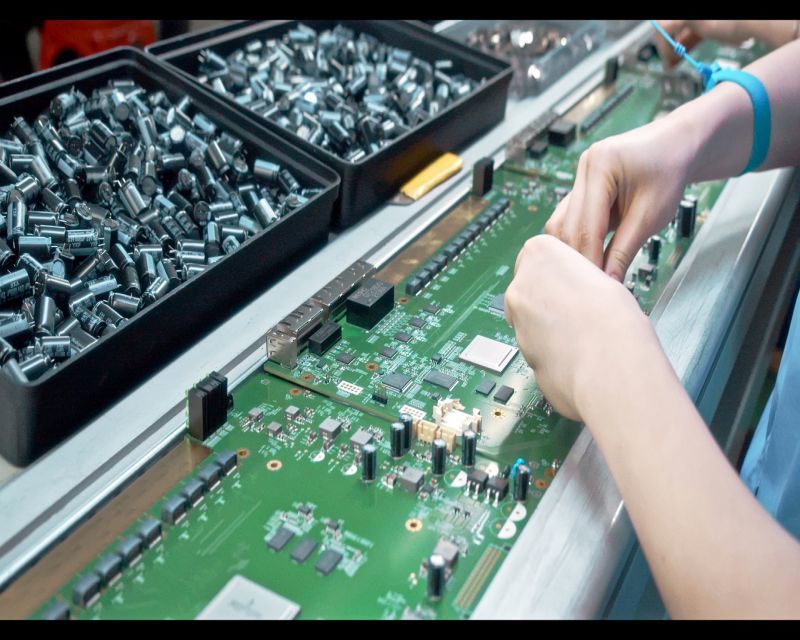

Visual inspection is performed to check that all components are in their proper places and that there are no obvious defects on the board.

In-circuit testing can detect various faults, including open circuits, incorrect connections, and short circuits.

Automated optical inspection checks the board for soldering faults, while flying probe testing uses probes to find holes, short circuits, and other defects. Due to the greater difficulty of the procedure, flying probe testing is usually used as a supplementary method to verify the results of more direct tests.

What are some commonly used PCBA testing and inspection methods?

X-ray inspection, automated optical inspection, solderability testing, in-circuit testing, and functional component testing are just a few of the common PCBA tests and inspections.

Solderability testing and X-ray inspection help ensure that all components are properly assembled. ICT

and FCT are used to ensure the board functions correctly as a whole, while AOI is used to quickly find and classify problems in surface mount components.

These inspection and testing procedures will guarantee that the PCBA components used in the final product are of high quality and will function reliably.

What common defects can PCBA testing detect?

PCBA testing can detect various defects, including incorrect components, incorrect solder joints, assembly problems, missing or improperly installed components, poor wire connections, and corrosion.

Mechanical failures such as missing or loose screws, broken or misplaced parts, incorrect dimensions, and incorrect orientation can also be identified.

Considerations When Choosing a PCBA Testing Manufacturer

Consider the cost, reliability of service, how quickly you can get results, how the staff will help if you have any problems, and if you have any questions.

Future manufacturers of PCBA testing equipment must be familiar with relevant regulations and safety standards.

In addition, they should have experience testing products similar to the ones being evaluated. Therefore, it is crucial to ensure that the PCBA testing manufacturer uses advanced instruments and technology when performing the tests.

Previous

Next

Previous :

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs