Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

History of Surface Mount Technology

Due to the thermal cycling experienced by the potting material, solder joints may sometimes be damaged; the confined space makes repairs more difficult; the solder may also weaken due to mechanical stress, so components that directly interact with the user may need to be connected using through-hole mounting.

More and more manufacturers are adopting surface mount technology (SMT) in printed circuit board assembly. SMT's development began in the 1980s, although the technology had existed for 20 years prior.

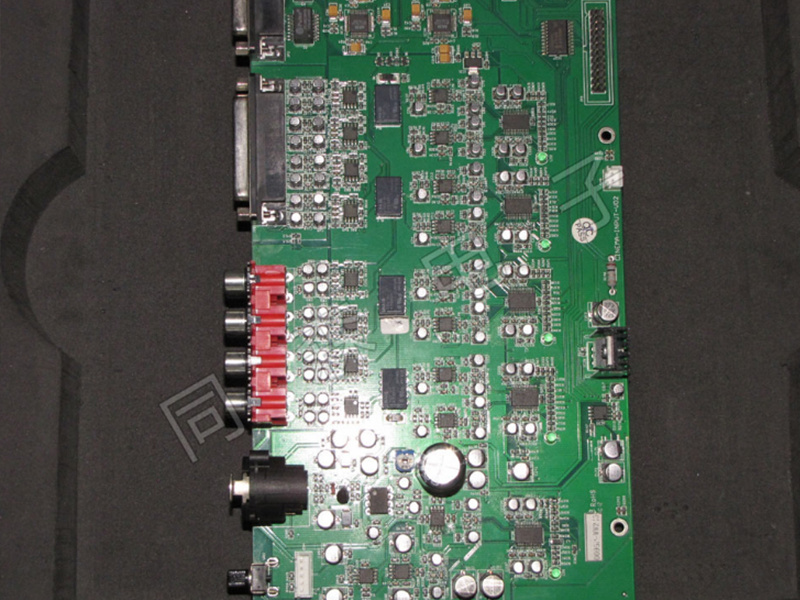

SMT is the process of mounting electronic components directly onto the surface of a printed circuit board. Components mounted in this way are called surface mount devices. This method has largely replaced the through-hole technology method.

History of SMT

The application of surface mount technology began in the 1960s, initially known as "planar mounting." In 1960, IBM, a leading American computer manufacturer, first demonstrated the technology in a small computer; this design was later used in the digital computer of the launch vehicle used by NASA for its space program.

SMT was used in the instrumentation of the Saturn V rocket (the heavy-lift launch vehicle used by NASA in the Apollo moon landing program from 1967 to 1973). Later, it was used in the Saturn IB rocket that launched the Apollo spacecraft into orbit in 1973, during crewed lunar flight training.

Saturn IB also launched the American space station Skylab in May 1973. It was later used in the Apollo-Soyuz Test Project of 1975—the first joint crewed international space mission between the US and the Soviet Union.

Despite a good start, surface mount technology did not become popular until the mid-1980s. Until 1986, surface mount components only accounted for about 10% of the entire market.

However, the technology began to rise in the late 1980s, and by the late 1990s, most high-tech electronic printed circuit boards used surface mount devices. Today, SMT is widely used in the vast majority of applications.

How SMT Works

Components are designed with small metal tabs and soldered directly to the surface of the PCB. This allows for smaller components—currently, small components are called 01005, measuring only 0.4 x 0.2 mm!

Compared to through-hole mounting, surface mounting is more common to place components on both sides of the board. This allows for smaller circuit boards and higher circuit density. In turn, the sub-assemblies and machines containing the circuit boards can also be smaller.

Due to continuous technological changes, manufacturers have the ability to create high-quality work in smaller areas.

Advantages of Surface Mount Technology

There are many benefits to using SMT. Importantly, it reduces the need for manual intervention, thus reducing the possibility of errors. This can also reduce labor, production, and management costs.

Repetitive operations support a more effective quality control process. Previously, quality was checked after production. Today, more advanced preventative techniques are used: checking and confirming components as part of the process and a batch of products as they run.

SMT improves operational and production speed while increasing circuit density and functionality. The technology reduces heat generation and power consumption during the production process. Notably, surface mounting is very useful when combined with through-hole technology.

The surface tension of the molten solder pulls the component into alignment with the pads, automatically correcting small errors in component placement. This process reduces resistance and inductance at the connection, providing better high-frequency performance while reducing the adverse effects of RF signals.

Disadvantages of Surface Mount Technology

While there are many benefits to using SMT, there are also some drawbacks, including the potentially high investment cost in machinery.

Solder joints can sometimes be damaged as the encapsulating material undergoes thermal cycling; the tight spaces make repairs more difficult; solder can also weaken due to mechanical stress, so components that directly interact with the user may need to be connected using through-hole mounting.

However, its disadvantages are often offset by its advantages, primarily because SMT enables increased manufacturing automation, lower costs, and improved quality.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs