Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Why is SMT favored by the electronics manufacturing industry?

Regardless of your intended use for the printed circuit board, manufacturing a board that is reliable and performs at a high level throughout its lifespan is key. If your team has a reliable SMT electronics manufacturer, you should be able to achieve this goal easily.

SMT has gradually replaced THT. What are the advantages of this technology, and why do turnkey PCB assembly manufacturers favor it? Let's explore the advantages of this technology.

High Assembly Density

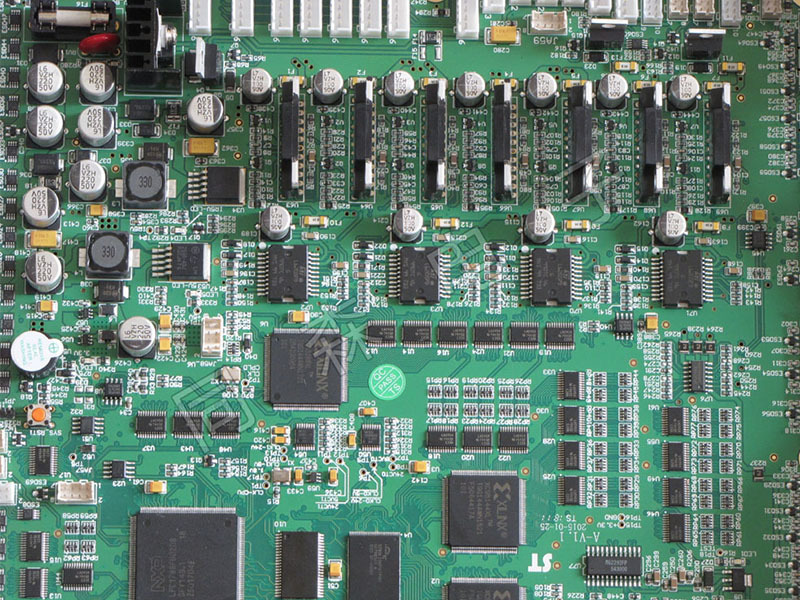

Compared to traditional DIP technology, SMD components allow for smaller assembly areas and lighter weight. PCBA products assembled using SMT are 40% smaller in volume and 35% lighter in weight than those using DIP. DIP components are mounted on a 2.54mm grid, while SMD offers better performance. To meet customer demands for smaller electronic products, FS Technology's SMT technology has become increasingly mature, with our surface mount assembly component grid evolving from 1.27mm to 0.63mm, and some special components can even be mounted on a 0.5mm grid.

More Reliable Technology

Due to their small size and light weight, SMT components offer higher shock resistance and reliability. In producing SMT assembled products, Foshan Technology uses 7 fully automated production lines. Our production lines have strict quality control standards, with a general defective solder joint rate of less than ten parts per million. The wave soldering technology for through-hole components is an order of magnitude lower. The average MTBF for electronic products assembled using SMT is 250,000 hours, which is the main reason why 90% of electronic products use SMT processes.

Good High-Frequency Characteristics

Surface mount components, unlike plug-in components, generally use leadless or short-lead direct surface mounting and soldering, which can greatly reduce the impact on circuit inductance, large-capacity capacitors, and resistors. For a project, the MHz of the PCBA board is very important, and using surface mounting can increase the frequency of the circuit. By comparing SMD and THT, it is found that the high frequency of circuits designed using surface mount technology can reach 3GHz, while the high frequency of through-hole technology is only 500MHz. Because SMD has high-frequency characteristics, it can shorten the transmission time of your circuit board, which is very important for electronic products such as computers that have high requirements for transmission time.

Reduce assembly project costs;

Reduce the number of holes drilled on the PCBA board;

Reduce the cost and time of debugging circuit boards;

Reduce packaging, transportation, and warehousing costs;

The price of surface mount resistors is comparable to that of through-hole resistors;

Easy to achieve automated production;

Surface mounting is a technology that makes large-scale automated production easier. We have 7 SMT lines, all using automated SMT equipment to pick and place SMD components with vacuum nozzles. Because these vacuum nozzles are smaller, the assembly equipment can assemble with higher precision. In fact, most PCBA companies now produce through automated surface mounting. If a turnkey PCB assembly company wants to use THT technology for large-scale automated production, it needs to increase the area of the PCB bare board to at least 140%.

How to choose a PCBA SMT assembly manufacturer?

The above content covers almost everything that electronics enthusiasts might be interested in, but if you are a PCBA engineer urgently looking for a PCBA factory to provide SMT assembly services, then the following content is a must-read!

Engineers invest a lot of effort in printed circuit board projects before assembly. Therefore, choosing a better SMT supplier for assembly is crucial. Choosing a company to work with can be challenging because there are too many options, and this choice is very important. If you need to choose a PCB assembly company, how do you determine which company is right for your project? For your convenience, we have listed the services that companies should provide to customers:

The manufacturing plant has advanced machinery and tools to handle the difficulties of manufacturing complex PCBs.

Experienced engineers are ready to assist you throughout the process and ensure everything runs efficiently.

High-quality materials—the company only uses high-quality SMT SMD components to ensure that the quality of the circuit board meets and exceeds user expectations.

Delivery within the specified time. This shows that the company can complete mass production orders in a short time. The company guarantees to complete manufacturing within the specified time.

Reasonable price; customer satisfaction is the company's focus. Therefore, you can expect reasonable costs suitable for any financial plan.

Summary

No matter what you want to use your printed circuit board for, manufacturing a board that is reliable and has a high performance level throughout its lifespan is important. If you have a reliable SMT electronics manufacturer on your team, you should be able to achieve this easily.

Although printed circuit boards contain more electronic components, assembling it is as important as designing and manufacturing it. As can be seen from this article, SMT assembly plays a significant role in almost all forms of contemporary electronic product design. If your PCB design still uses through-hole methods, SMT assembly can help your product move forward. Therefore, be sure to work with a trustworthy and knowledgeable assembly partner to avoid any potential problems with SMT assembly.

Previous :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs