Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Comparison of SMT with other technologies

Through-hole mounting is a process of inserting component leads into holes drilled in a bare PCB. While this was the standard practice before the 1980s, SMT was expected to completely replace its common uses. Despite the sharp decline in popularity and practicality of through-hole technology, it remains resilient—it has advantages and niche applications that SMT does not.

Through-hole and Surface Mount Technology

Through-hole mounting involves inserting component leads into holes drilled in a bare PCB. While this was standard practice before the 1980s, SMT is expected to completely replace its common uses. Despite the sharp decline in popularity and practicality of through-hole technology, it remains resilient—it has advantages and niche applications that SMT does not.

Through-hole is a reliable process suitable for products that require stronger interlayer connections. SMT components are secured by surface board solder, while through-hole components have leads that pass through the circuit board, allowing them to withstand higher environmental stresses. Because of this, through-hole technology is commonly used in aerospace and military products that experience extreme impacts, temperatures, acceleration, and weathering. Additionally, through-hole technology can be used for testing and prototyping applications that may require manual adjustments or replacements.

While through-hole may not be as widely used as it once was, it hasn't completely disappeared from PCBAs. Factors such as availability and cost determine whether a manufacturer uses SMT or through-hole—not all components are available, and sometimes through-hole technology is cheaper. It may be a secondary choice, but it's important that it remains an option for manufacturers.

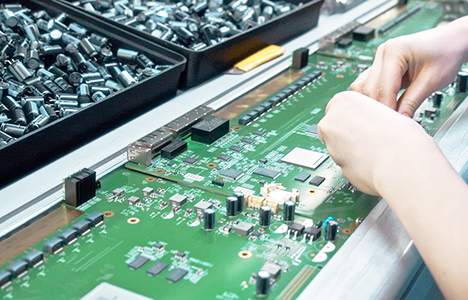

Surface Mount Technology allows components to be mounted directly onto the surface of a printed circuit board. Developed in the 1960s as a "flat mounting" process, SMT has become extremely popular since its mainstream adoption in the 1980s. Today, almost all electronic hardware is mounted using this process. It is crucial to PCB design, with manufacturers improving the quality, performance, and yield of PCBs while reducing labor, processing, and handling costs.

The main differences between SMT and through-hole mounting are:

SMT components are smaller

SMT does not require drilling holes in the PCB

SMT components can be mounted on both sides of the circuit board.

SMT allows for a high density of small components, resulting in denser and higher-performing PCBs.

Through-hole components have leads that pass through the board and connect layers of the board. These leads, known as "vias," are used to achieve conductive connections. These connections between different PCB layers essentially act as through-hole leads. Some surface mount components (e.g., BGAs) are higher-performance components with more interconnect pins for higher speeds.

Advantages: Due to the automation of SMT, the technology allows for smaller PCB sizes, higher component density, and more workspace. SMT requires fewer drilled holes, meaning lower overall costs and faster production times. SMT components can be placed thousands or even tens of thousands per hour during assembly, while THM components are less than a thousand per hour. Because programmed reflow ovens make solder joints on the PCB more reliable and repeatable, through-hole technology is less attractive and less feasible. Furthermore, SMT improves performance and stability, especially under conditions of shaking and vibration.

Disadvantages: SMT as a connection method can occasionally be unreliable, especially for components that are subject to mechanical stress. For external devices that are frequently manually connected and disconnected, through-hole technology is more suitable.

SMT is almost always more efficient and cost-effective than THM. Today, SMT is used in the vast majority of manufacturing—over 90% of PCBAs use SMT. However, there are still some specialized mechanical, electrical, and thermal manufacturing needs that require through-hole processes, meaning that SMT will remain an important secondary option for years to come.

SMT and Chip-on-Board (COB) Technology

Chip-on-board assembly differs from SMT in that it mounts bare semiconductor chips directly onto the PCB. Using either non-conductive or conductive epoxy, manufacturers can use aluminum wedge bonding or gold ball bonding to achieve electrical connections.

COB gives system designers unique assembly options not offered by SMT. The die is then directly bonded to the PCB surface to establish electrical connections, and an epoxy coating is applied over the die to protect it from shock and light.

Chip-on-board is a good choice for miniaturized circuits and LED circuits because it offers a better solution when traditional assembly techniques cannot meet the required design parameters.

Benefits of COB Technology:

Supports high-voltage or low-voltage designs

Allows for custom coatings

Double-sided multilayer boards

High-volume or low-volume functional board testing

Multiple temperature ranges

Chip-on-board technology is "advanced" SMT, as their main difference is that COB involves high lead counts, active devices, and does not require ceramic or molded plastic to protect the external device package.

Advantages: COB significantly reduces circuit weight, meaning that chip-on-board assembly is the ideal solution when weight is a primary factor. COB also offers enhanced reverse engineering protection, lower costs, improved performance results, minimized space requirements, improved reliability due to heat distribution, a wider range of applications, and a lower number of solder joints. COB is also more productive than SMT.

Disadvantages: COB LED packaging has higher maintenance costs and lower yields. The manufacturing cost is also higher due to a higher defect rate. The quality of LED light sources for COB and SMT also differs, as SMT is multiple point light sources connected together, while COB has more uniform illumination.

SMT Applications

Extreme care must be taken when applying surface mount components to circuit boards. Soldering such small components is a painstaking and delicate task, so specialized equipment is required if you are willing to do so. Applications can be done in different ways, just as they were in the past. However, they are manufactured this way because of the significant cost savings associated with the process.

SMT Advantages

SMT has many advantages that benefit many areas of life. Not only is it faster to manufacture and has lower installation and running costs, but there is also less chance of error. Surface mount technology is machine automated, eliminating errors caused by human fumbling.

Furthermore, the smaller size produced by surface mount technology makes the entire product more compact. Smaller internal components allow for more streamlined external packaging and dimensions.

As an environmental health benefit and advantage, as well as a quality advantage, surface mount technology uses lower resistance and inductance at connection points. Therefore, fewer unwanted RF effects are present. This reduction allows for better and more predictable high-frequency performance. The use of SMT reduces radiated emissions due to smaller radiation loop areas and lower lead inductance.

Conclusion

Surface mount technology is no exception. With the introduction of this new technology, the speed at which popular products are brought to market has increased significantly. In addition, the cost of producing such products has also been steadily decreasing. Due to faster and more efficient technology, labor costs are reduced, and the way the same product is produced is vastly different.

Surface mount technology is a widely popular process that has brought incredible benefits to many different areas of life. This new technology has propelled the world forward in ways previously impossible.

Next

Previous :

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs