Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

In-depth Guide to Manufacturing PCB Ring Circuits

Now let's look at the role of the annular ring. As we all know, PCBs are multi-layered, and vias are interconnection nodes between different layers on the PCB. The good connection between the copper wires and vias in multi-layered PCBs depends on sufficient copper around the vias, so the annular ring plays a supplementary role, enhancing the connection between the vias and the copper wires. In other words, the connectivity is proportional to the thickness of the ring. The thicker the ring, the stronger the connectivity.

What is an annular ring in a PCB?

An annular ring in a PCB is a type of circuit board ring. "Annular ring" is a professional term; it's called an annular ring because the vias, when viewed from above, appear ring-shaped. According to the PCB annular ring definition, an annular ring refers to the area between the hole drilled by the via and the edge of the conductive copper pad. It can also be understood as the copper surrounding the via. The size of the annular ring is determined by the size of the via and the copper pad.

Now let's look at the function of the annular ring. As we all know, PCBs are multi-layered, and vias are interconnection nodes between different layers on the PCB. The good connection between the copper wires and vias in multi-layer PCBs depends on sufficient copper around the vias; therefore, the annular ring plays a supplementary role, enhancing the connection between the vias and the copper wires. In other words, connectivity is proportional to the thickness of the ring. The thicker the ring, the stronger the connectivity.

The Importance of PCB Annular Ring Size

First, we need to know that the PCB annular ring surrounding the via serves to connect the copper wires and different layers of the PCB. In addition, annular rings have different sizes and thicknesses. Due to manufacturing requirements, space limitations, tolerances, and other influencing factors, some PCB designers will choose a more appropriate PCB annular ring thickness based on the above factors.

When choosing an annular ring, the size of the PCB annular ring should be considered. A crucial point to know is that a thicker PCB annular ring provides better connectivity. Therefore, the width of the annular ring should be thick enough to support a reliable connection with the annular ring PCB via. Click to read more detailed PCB hole knowledge. To ensure things are successfully completed, two methods are commonly used.

1. The nominal width of the annular ring in PCB design is less than the smaller value of the annular ring length;

2. The smaller value of the annular ring length is consistent with the nominal width of the annular ring.

Failure to follow the above two practices may lead to pad cracking or other connection problems.

A teardrop annular ring is a typical example of adding more copper to improve connectivity to withstand more stress. A teardrop annular ring works by adding more copper around the connection point where the PCB annular ring connects to the PCB trace. The purpose is to obtain stronger stress resistance and a safe, stable connection.

In short, the size of the PCB annular ring is very important. The thickness of the PCB annular ring determines the connectivity. There is a positive correlation between them.

How to Calculate Annular Ring Size?

Now that we know the importance of PCB annular ring size, we need to figure out how to correctly calculate the PCB annular ring size and the calculation formula.

As for how to calculate the PCB annular ring size, it can be achieved through the following formula:

Annular Ring = (Pad Diameter - Via Diameter) / 2.

For example, if the pad diameter is 28 mil and the hole diameter is 10 mil, you can calculate the answer like this: (28-10)/2=9 mils.

Pad diameter 10mil, hole diameter 4mil: (10-4)/2=3 mils;

Pad diameter 24mil, hole diameter 8mil: (24-8)/2=8 mils;

Pad diameter 30mil, hole diameter 12mil (30-12)/2=8 mils;

In practical applications, in addition to calculating the width of the ring, it is also necessary to calculate the width of the annular ring for standard vias, micro vias, and component holes.

Precautions for Through-Holes in Annular Rings

The ideal placement of the through-hole is in the exact center of the pad.

One point to note during the manufacturing of the annular ring is that the through-hole must be formed in the exact center of the pad; otherwise, the minimum value of the annular ring width will definitely exceed the specified value. When the through-hole is misaligned relative to the pad, the edge interconnections may experience increased resistance, and reliability will also decrease.

Provide More Space for the Annular Ring.

Every PCB manufacturer will specify annular ring tolerances. To be safe, adding a little extra space is always a good idea. Most PCB annular ring designers recommend increasing the annular ring PCB size by 1.0 mm. A little extra width will help prevent any future problems.

Depending on the intended use of your designed board, the size of the annular ring will also vary. The Printed Circuit Board Association specifies three PCB standard categories (Class 1, Class 2, Class 3). Heavy-duty PCBs require larger annular rings due to larger via diameters. Class 3 PCBs require more heavy-duty annular rings.

Why Use Teardrop Pads?

Teardrop PCB pads are teardrop-shaped, meaning that extra copper is added at the junction of the annular ring and the trace to give the ring some extra strength.

Applicable situation: The drill bit deviates slightly from the direction during the drilling process.

As follows, teardrop pads can:

Reduce the risk of copper cracking;

Enhance structural integrity;

Increase pad tolerance;

Protect against minor misalignment in drilling.

IPC Standards and Manufacturing Tolerances for PCB Annular Rings.

IPC-6012 Class 3 annular ring dimensions. IPC standards define three classes, Class 1, Class 2, and Class 3, based on the required level of equipment reliability. Each of these classes specifies its own acceptance criteria and quality requirements standards for PCB cleaning, manufacturing, and inspection. These standards can address issues such as through-hole plating, component placement, residual contaminants, trace dimensions, and other design-related issues. To make the manufactured plated through-holes acceptable, we must ensure that each annular ring in each class has sufficient extra space. Therefore, determining the annular ring size is the process of selecting the correct size for your through-holes. With sufficiently large through-holes, you can accommodate manufacturing tolerances in your PCB.

Previous :

RECOMMENDED NEWS

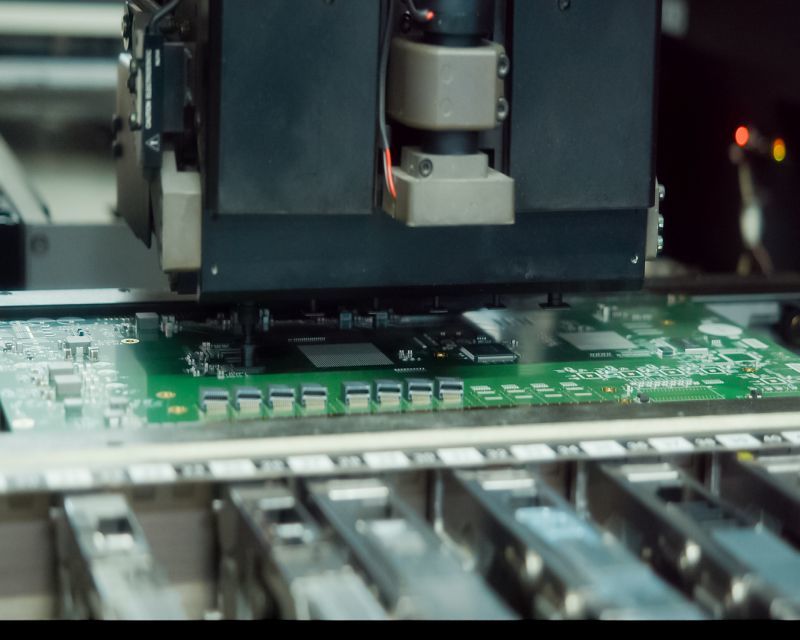

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs