Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

How to maximize the first-pass yield in SMT production

SMT production technology took nearly 30 years to become popular. However, since then, it has become increasingly popular, especially for improving the size and efficiency of electronic products. Cooperation with the right partners means more reliable delivery times and better quality output. Both of these can be attributed to the use of SMT production processes.

Printed Circuit Board (PCB) manufacturing is a process that requires precision and reliability.

With advancements in technology, laptops and smartphones have become smaller yet capable of holding more data and performing complex tasks. This is partly due to the ability to install more efficient and complex PCBs in these devices - a result of advancements in production technology.

Finding the right partner that uses advanced surface mount technology (SMT) will help ensure your PCBs are project-ready upon delivery. Partnering with the right electronics contract manufacturer means the difference between receiving PCBs that are ready for installation or receiving defective circuit boards that will delay factory production.

What is Surface Mount Technology? Overview and Advantages

By definition, surface mount technology involves adhering components to the surface of a circuit board instead of the traditional method of inserting leads through holes in the board.

The SMT assembly process was created in the 1960s but didn't become popular until the mid-1980s when the process was improved. By 1990, surface mount devices (SMDs) had become a popular integration method. The SMT production process has significant advantages that greatly improve operational yields, including:

Improved inventory and delivery times;

Addressing component shortages;

Addressing labor shortages by having fewer people manage more production lines;

Optimizing operator performance;

Another significant advantage of SMT production is its ability to achieve a higher degree of automation integration. This integration reduces production costs while increasing output.

SMT manufacturing can also efficiently place smaller components. Current processes allow for the placement of components as small as 0201 packages, measuring 0.25mm x 0.125mm. A chip placement machine production line consisting of four machines can place these components at a rate of 100,000 parts per hour. Each machine averages 25,000 components per hour.

The process is also more efficient because components can be easily sorted and adhered to the board without worrying about human error.

SMT Manufacturing and Matrix

SMT involves several steps, from material preparation and the design phase to programming the machines to successfully complete the task and design implementation.

There are two possible methods for adhering components to the board:

Stencil printing, which uses a stencil-based screen printing technique to apply solder paste, utilizes a metal squeegee to apply the necessary force to move the solder to the stencil and onto the PCB.

Jet printing is an increasingly popular method. Similar to an inkjet printer, with jet printing, solder paste is rapidly ejected, utilizing fluid momentum as energy, to flow through a nozzle in a specific volume. This no-contact dispensing method can typically better customize the thickness of the solder paste applied.

Next, the components are placed on the solder paste, followed by reflow soldering, then cleaning and inspection.

Main Components of an SMT Production Line

Due to the sophistication of SMT production lines, the setup process requires specific and strategic planning to optimize product flow. This meticulous planning improves product operational efficiency, allowing for reliable speed of flow and ensuring on-time order delivery.

The process includes:

Solder paste application and inspection;

Pick and place machine;

Pre-reflow AOI inspection;

Reflow oven;

Post-reflow AOI;

1. Solder Paste Application and Inspection

Solder paste is tiny solder particles suspended in flux. Typically, solder paste is identified as Type 3, 4, or 5. The type number indicates the size of the particles in the solder powder. The solder paste is meticulously applied according to a precise design created through a computer software program. During solder paste inspection, the volume and alignment will be assessed to ensure accuracy.

Slight misalignment can lead to defects on the board, while insufficient or excessive solder paste will affect the overall quality and lifespan of the product. It also assesses any scratches or imperfections that may have occurred during the solder paste application process.

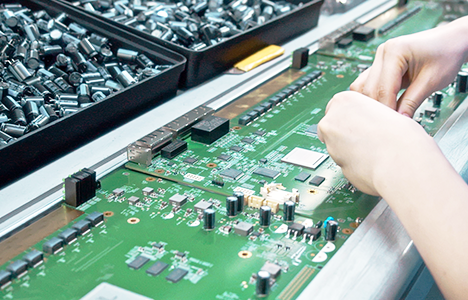

2. Pick and Place Machine

After the solder paste is applied, the components for the PCB will be placed on the circuit board via a pick and place machine. These machines can be placed in series to increase output.

3. Pre-reflow AOI Inspection

Next, the PCB goes through an automated optical inspection (AOI) station.

AOI is a visual inspection method used to detect defects. This method is best suited for high-volume production environments.

AOI is very time-consuming and often complex, requiring hours of programming and the setting of specific location checks for the PCB's components.

AOI sets narrow parameters to inspect a specific design or component configuration. AOI PCB inspection is especially important after solder reflow.

This inspection method can detect component placement defects or solder defects.

4. Reflow Oven

For SMT production lines, the reflow oven melts the solder paste through a four-step process:

Preheat;

Soak;

Reflow;

Cool down;

During this process, the components are permanently adhered to the circuit board at optimal temperatures to set the solder paste without damaging the components or affecting the overall quality of the board.

Reflow soldering is precise and saves production time.

5. Post-reflow AOI

Post-reflow AOI is an inspection performed after the product has passed through the reflow oven. This inspection aims to detect issues found in previous product runs, such as missing components or poor solder joints.

Through pre-reflow and post-reflow AOI, Matric was able to improve its run rate from 70% to 97%.

Matric Limited relies on surface mount technology for its PCB manufacturing process. This highly reliable process enables Matric to address run rate issues as well as component orientation and placement problems during PCB production.

SMT Production Instructions: Reasons for Today's Technology

The SMT production process took nearly 30 years to become popular. However, since then, it has grown increasingly popular, especially for improving the size and efficiency of electronic products. Working with the right partners means more reliable delivery times and better quality output. Both of these can be attributed to the use of the SMT production process.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs