Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

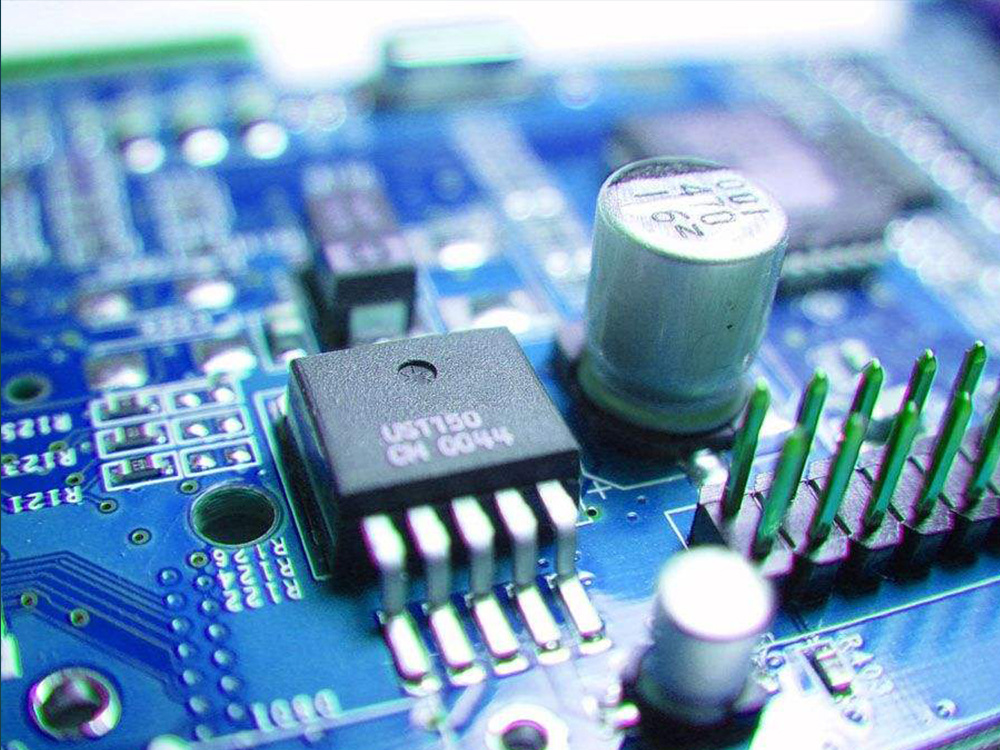

DFM inspection

Check the items of customer's design PCB, BOM, schematic diagram, finished product assembly manual:

• Document version and last update time

• Process: lead/lead -free

• Clear component tag number and silk screen

• Including manufacturer's brand and part number, BOM of description and bit number

• Confirm the PCB manufacturing process: material, board thickness, copper thickness, number of layers, surface treatment, character color and special process

• Reasonable PCB layers and paneling methods

• Provide correct SMT patch files

• Complete program programming and functional testing solutions

• Clear finished product assembly manual and schematic diagram

• Other special process requirements

Previous

Next

Previous :

Next :

MORE BUSINESS

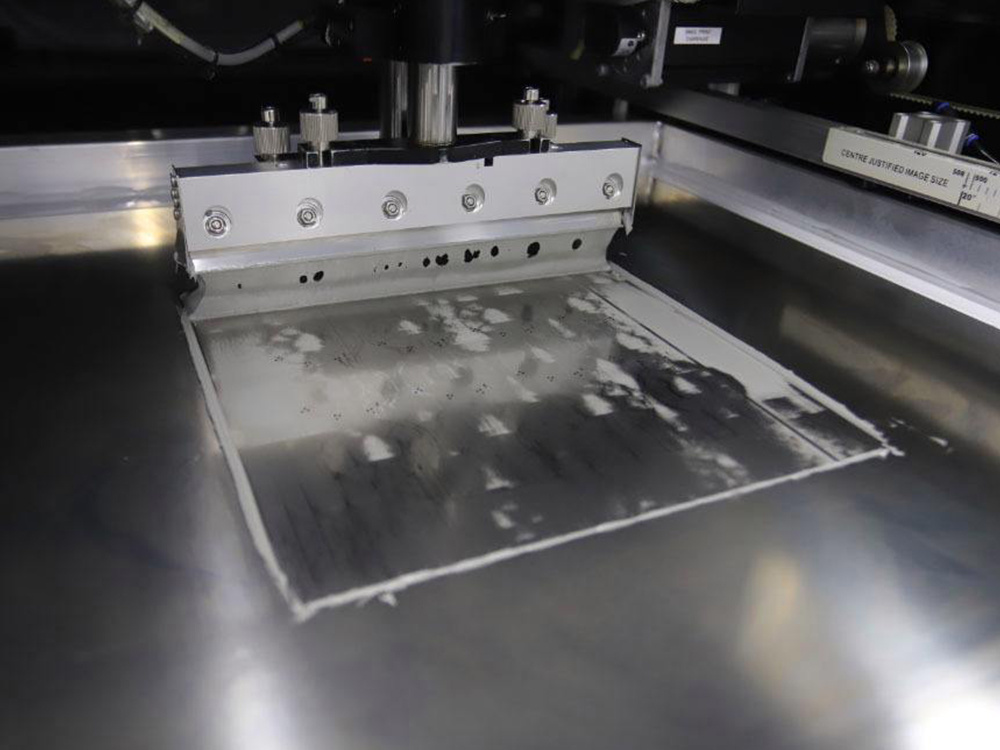

Component Storage and Solder Paste Printing