Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

IQC incoming inspection

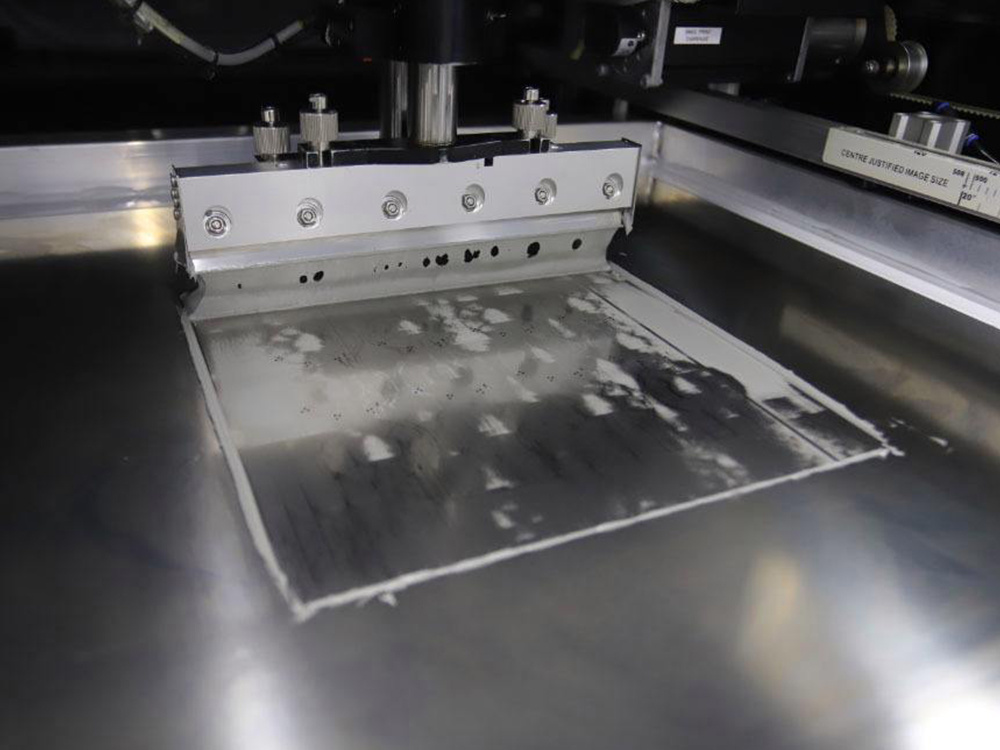

•Measuring the thickness of a PCB

•Check the through holes of the PCB and whether the ink is blocking the holes, etc.

•Check whether the PCB is warped and deformed, and whether the silk screen is clear

•Check the PCB for defects such as broken wires, jumpers, etc.

•Place the PCB in reflow soldering for oven temperature test to check for yellowing or deformation

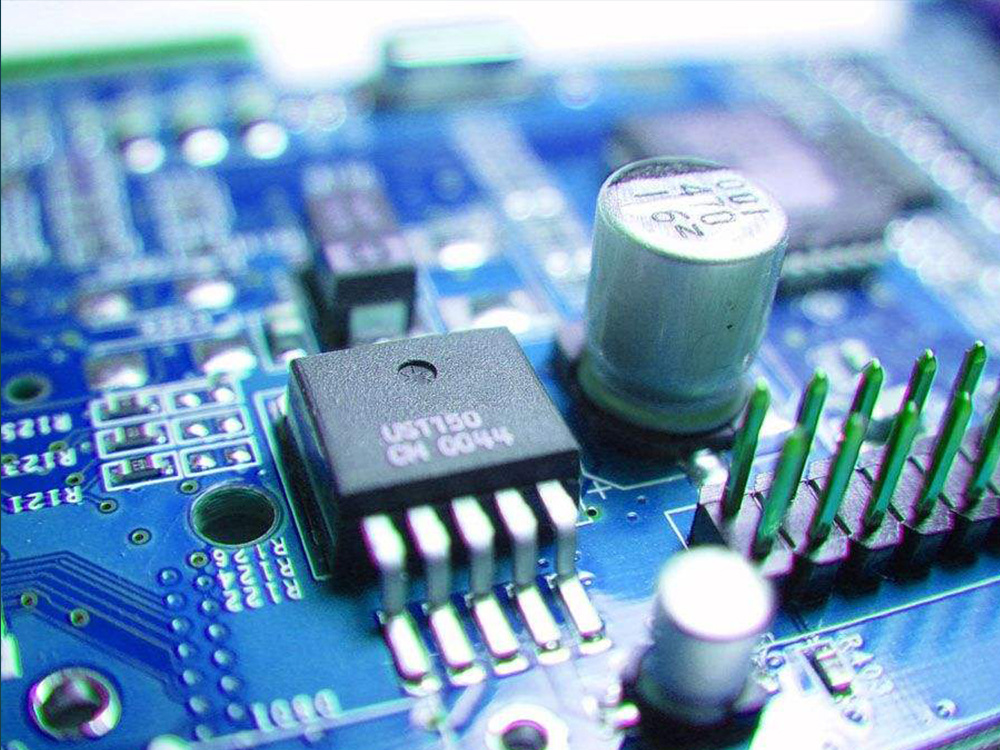

•Check whether the batch number, part number and silk screen of incoming electronic components are consistent with the BOM

•Incoming electronic components are placed on the bare PCB board for pad or through-hole adaptation testing

•Sampling check the resistance, capacitance, etc. of incoming electronic components, and compare with BOM

•Check the surface of incoming electronic components for scratches, deformation, broken feet, short feet, etc.

MORE BUSINESS

Component Storage and Solder Paste Printing