Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

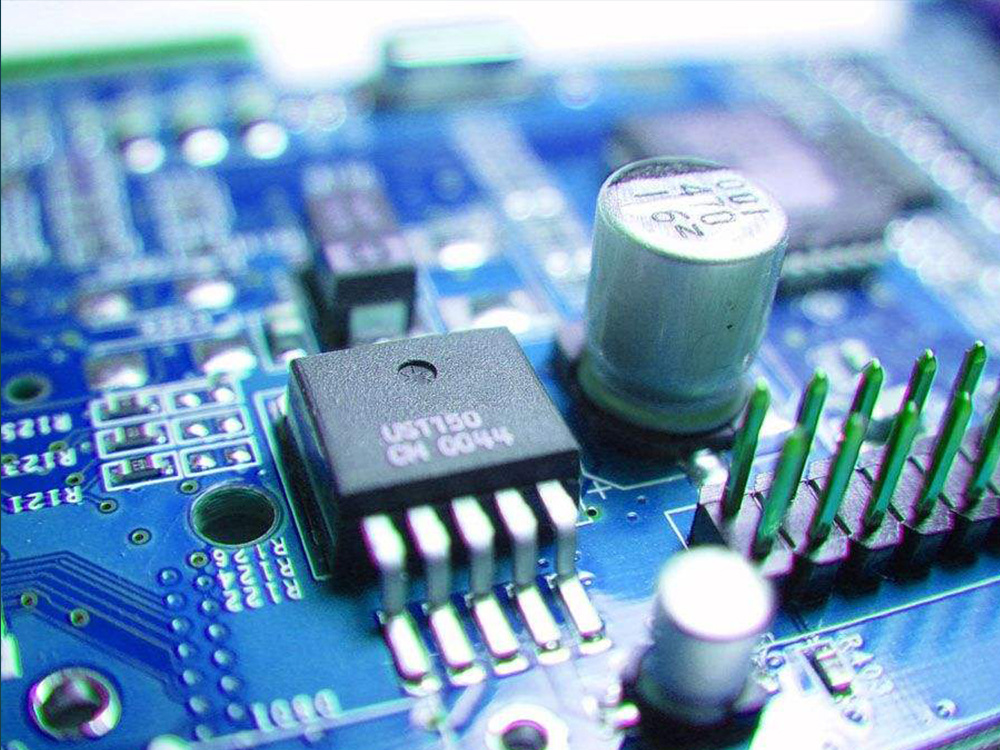

PCB fabrication

We outsource PCB production and strictly control the following key quality points

•High-quality brand board

•Choose a well-known circuit board supplier

•Continuously build supplier relationship management

•Have the ability to complete 3mil line width and line spacing, multi-layer, HDI, impedance, blind buried via

•All PCBs delivered to our company must be 100% electrical tested

Previous

Next

Previous :

Next :

MORE BUSINESS

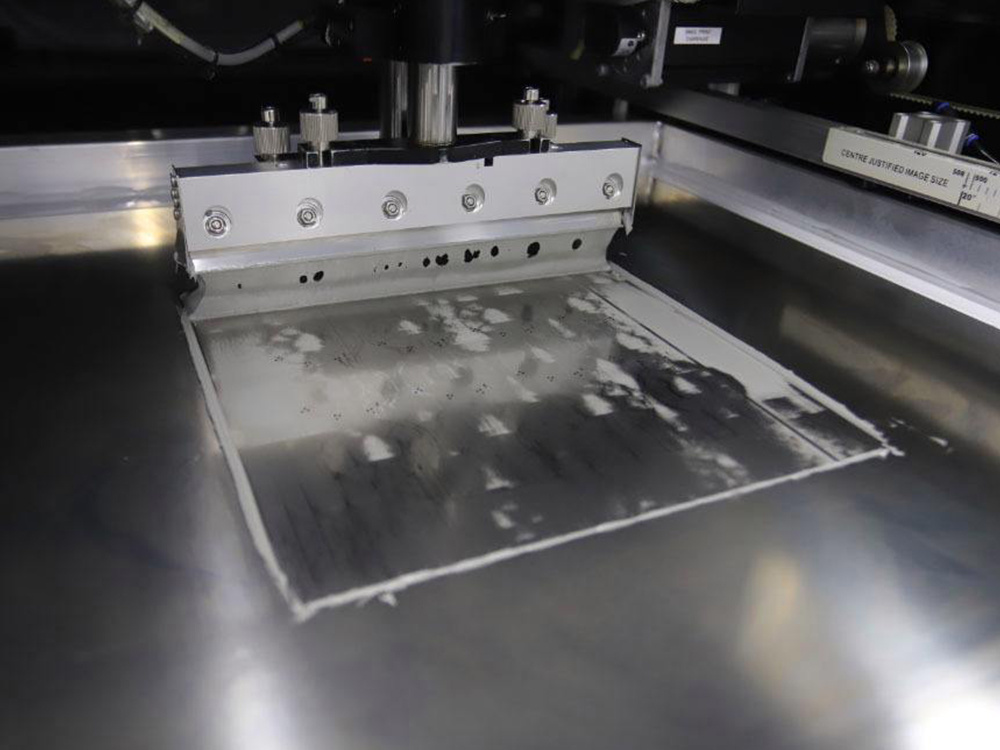

Component Storage and Solder Paste Printing

Sensitive components are stored in a professional constant temperature and humidity box

Bake some demanding PCB/IC/BGA for 2-12 hours to remove surface moisture and enhance solderability

Use first-line brand solder paste

Issuing high-quality laser stencils

Complete solder paste freezing, thawing and stirring procedures

Equipped with a fully automatic solder paste printing machine to ensure the consistency and reliability of solder paste printing during mass production