Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Advantages of SMT Surface Mount Technology Processing: A Key to Improving the Quality of Electronic Products

In today's rapidly developing technological era, electronic products have permeated almost every corner of our lives. From mobile phones to home appliances, from automobiles to smart wearable devices, the quality of electronic products directly affects the user experience. Among them, SMT surface mount technology, as an efficient and precise method of assembling electronic components, is gradually becoming a key technology for improving the quality of electronic products. Let's discuss the advantages of SMT surface mount processing and its importance in SMT processing plants. What is SMT surface mount processing?

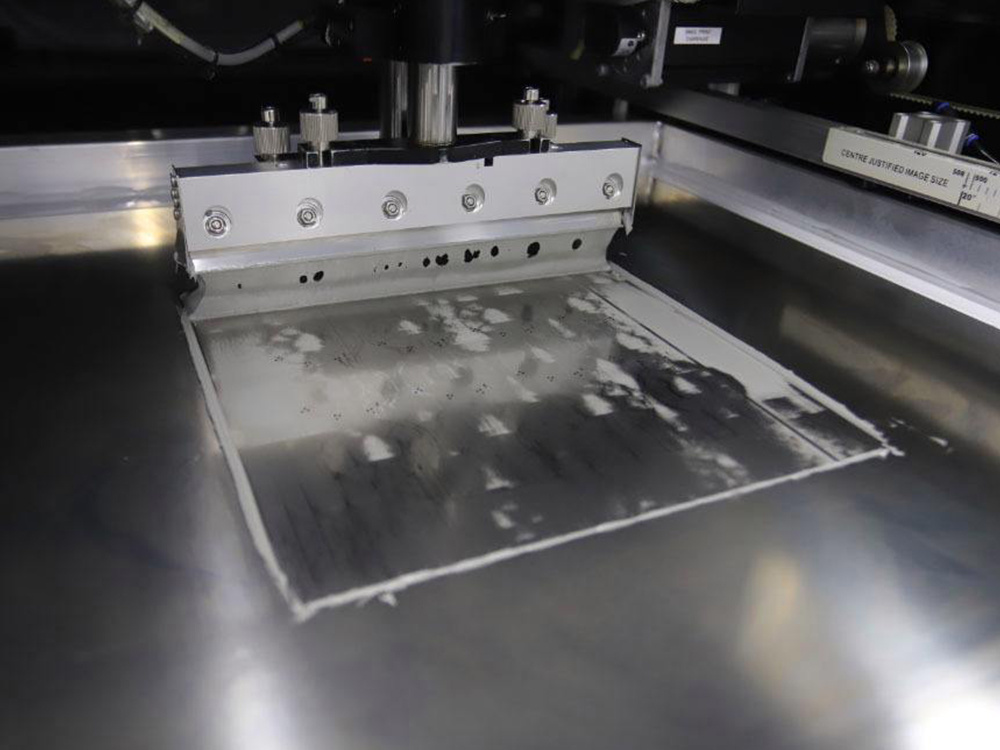

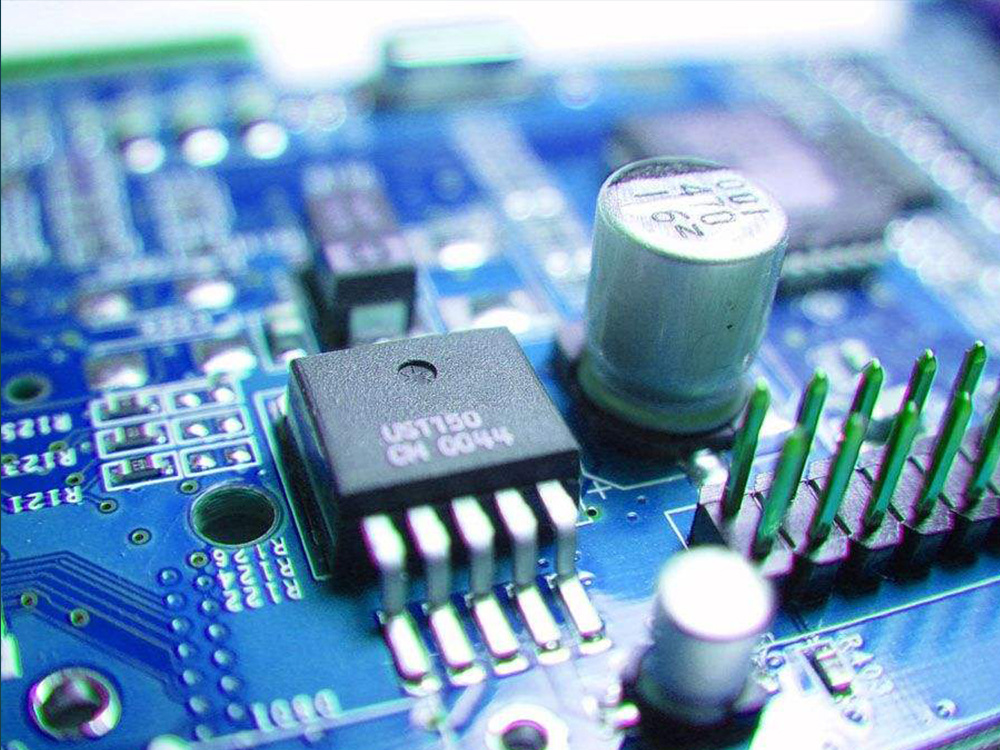

SMT, or Surface Mount Technology, is a technology that mounts electronic components directly onto the surface of a printed circuit board (PCB). This technology not only improves assembly efficiency but also significantly reduces the size of electronic components. In SMT processing plants, SMT surface mount processing is usually achieved through advanced machinery and equipment and strict production processes.

Advantages of SMT Surface Mount Processing

1. Improved Production Efficiency

Imagine if you were to assemble a complex electronic product manually; it would be not only time-consuming and laborious but also prone to errors. SMT processing plants, however, use automated equipment to complete a large amount of assembly work in a short time. This is like a highly efficient production line, where robots replace human labor, making the entire process smooth and fast.

2. Enhanced Product Quality

During the surface mount process, the use of precise equipment and strict quality control measures can effectively reduce welding defects and other quality problems. This is like a meticulous craftsman, ensuring that every detail is flawless. High-quality products also mean fewer rework processes and higher customer satisfaction.

3. Reduced Production Costs

Although the initial investment may be higher, in the long run, the automation level of SMT surface mount processing can significantly reduce labor costs and material waste. Imagine if your employees had to spend a lot of time on manual assembly every day; the resources and time consumed would undoubtedly increase significantly. Efficient SMT processing plants can minimize these unnecessary expenses.

4. Flexible Response to Market Demands

Market changes are always rapid, and consumer needs are constantly evolving. The flexibility of SMT surface mount processing allows SMT processing plants to quickly adjust production lines to meet the needs of different products.

Choosing the Right SMT Processing Plant

When choosing an SMT processing plant, companies need to consider several factors. First, the manufacturer's technological strength and equipment level; advanced equipment can guarantee production efficiency and quality. Second, the manufacturer's experience and reputation; a reliable partner can reduce unexpected risks and ensure smooth production. In addition, service quality is also a key point; good communication can provide guarantees for project advancement.

Clearly, SMT surface mount processing, as an advanced assembly technology, has undeniable advantages in improving the quality of electronic products. Whether in terms of production efficiency, product quality, cost control, or market responsiveness, SMT surface mount processing demonstrates its unique value. In the future, with the continuous advancement of technology, SMT processing plants will surely bring more innovation and development to the electronics industry.

MORE BUSINESS

Component Storage and Solder Paste Printing