Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What is prototype PCB assembly?

Prototype PCB assembly provides electronic product development teams with indispensable functional verification and proof-of-concept capabilities by transforming design files into functional boards with accurately and reliably soldered components.

Prototype PCB assembly provides crucial physical verification capabilities, accelerating electronic product development and design improvement by enabling early problem detection...

What is PCB prototyping?

A printed circuit board prototype is an initial version of a printed circuit board design created for proof of concept and testing. As a key step in electronic product development, building a prototype PCB provides a physical manifestation of the circuit schematic to check functionality, analyze signal integrity, and assess manufacturability before mass production. This process is also known as prototype PCB assembly.

Essentially, PCB prototype assembly enables developers and engineers to translate an electronic design into a tangible circuit board with components soldered. It bridges the gap between theoretical schematics and mass manufacturing, providing critical insights and optimization opportunities early in the cycle. The manufacturing and assembly processes are both crucial to prototype building. While PCB manufacturing focuses on transforming the CAD design into a physical board, prototype PCB assembly is the process of soldering electronic components onto these boards according to the Bill of Materials (BOM) requirements to build a functional prototype.

As a validation of design concepts and part of the product development cycle, prototype PCB assembly offers electronics companies and innovators the opportunity to mitigate technical and manufacturing uncertainty risks at a relatively low cost and lead time. Verifying functionality, safety, and performance metrics before mass production is an essential step. Therefore, selecting a qualified prototype assembly partner significantly impacts product success.

Why use prototype PCB assembly?

For most electronic hardware companies and developers today, investing in professional prototype PCB assembly services is worthwhile, primarily for the following reasons:

1. Verify design functionality and concepts: The primary goal of building a prototype board is to check the actual functionality and performance of the electronic design. By putting the schematic into a testable circuit board, prototype assembly verifies the design's correctness and detects potential flaws that might affect functionality. This verification process mitigates risks before mass production.

2. Accelerate product development and time to market: High-quality PCB prototype assembly, through early verification and problem detection, helps significantly shorten the development cycle. Studies show that prototyping is an efficient and cost-effective optimization and final design approach, rather than discovering problems after production investment, saving over 60% of overall engineering time.

3. Facilitate demonstrations, marketing, and funding: An assembled PCB prototype allows innovators to showcase product viability and technological capabilities, thus securing marketing leads, early adopters, and investor funding before production. For hardware startups, an impressive prototype can build a business case to secure funding for further development.

4. Optimize Design for Manufacturing (DFM): By more closely mirroring real-world manufacturing processes, prototype assembly can uncover Design for Manufacturing (DFM) issues and design flaws for optimization. This reduces subsequent surprises and enables a more efficient transition from prototype to mass production.

In essence, investing in professional PCB prototype assembly services creates significant value. It efficiently translates designs from ideas into fully functional circuit boards, enabling proof of concept, performance verification, design improvements, demonstration showcases, and business case shaping before mass manufacturing.

Types of Prototype PCB Assembly

There are several key categories and techniques for assembling electronic components onto PCB prototypes, catering to different production needs:

Manual Assembly vs. Automated SMT Assembly

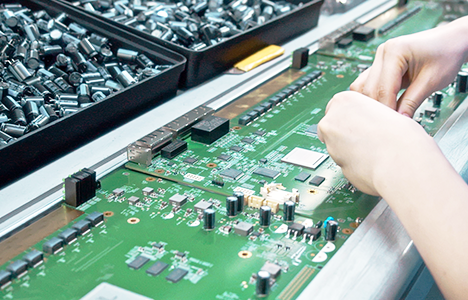

Simple prototype PCB assembly involves technicians manually soldering components, suitable for very small batches or limited order quantities. However, automated surface mount technology assembly offers higher efficiency, consistency, and manufacturability for complex board production.

Through-Hole vs. SMT Assembly

Through-hole components have leads for connection that go through holes in the board, while SMT, or surface mount components, are soldered directly to surface pads. Both Through-Hole Assembly (THA) and SMT assembly have their applications. Advanced technologies allow for a mix of THA parts on primarily SMT boards.

Single-Sided vs. Double-Sided Assembly

How components are placed and soldered on a PCB largely depends on the design—from simple single-sided prototype PCB assembly to more complex double-sided assembly, which solders parts on both sides of the board, enabling higher overall component density.

Mixed Assembly Technologies

With advanced manufacturing capabilities, leading prototype assembly services allow for a mix of components on the board, such as combining miniature 0201 size chips with larger SMT parts and some through-hole passive components on a double-sided board to optimize production. This mixed assembly provides the needed flexibility.

In summary, professional prototype PCB assembly partners offer a range of proven assembly processes, from simple manual builds to advanced automated mixed production (small to medium quantities), providing the right solution for clients' prototyping needs before mass production orders.

Prototype PCB Assembly Process Steps

Whether utilizing automated SMT production lines or manual assembly, the professional process of assembling prototype PCBs typically follows standardized assembly stages to realize the CAD design as a functional board:

SMT Pick and Place Stage

The core process utilizes advanced pick-and-place machines to selectively mount components onto the board according to optimized programming and feeder setups. High precision and traceability are ensured during this high-volume component placement stage.

SMT Reflow Soldering

After component placement, the board passes through an industrial reflow oven, where SMT parts are precisely soldered simultaneously under carefully optimized thermal profiles to permanently attach the parts to the board surface.

Cleaning/Washing

Once any board repair rework is done, the assembly process continues with a thorough cleaning of flux residue from the post-soldering board surface using cleaning solutions, ensuring ionic cleanliness.

AOI and Functional Testing

Quality checks are performed after the assembly stage—Automated Optical Inspection checks component placement, while rigorous functional testing uses methods such as fixture testing to check if the board's performance metrics meet specifications, followed by programming the final firmware version onto the board.

Final Programming/Flashing

These downloads bring the optimized software/firmware build onto the board via interfaces, completing prototype PCB assembly for design verification before delivery to the client.

In short, by adhering to robust assembly protocols and quality management systems, professional PCB assembly partners can deliver fully functional, reliable, and clean prototype boards within short lead times.

The Importance of Prototype PCB Assembly

Prototype PCB assembly provides electronic product development teams with indispensable functional verification and proof-of-concept capabilities by translating design files into functional boards with accurately and reliably soldered components.

Assembly quality directly impacts downstream processes, from design optimization to securing production financing. Therefore, quality considerations, cost balancing, responsive turnaround, and technical coordination are critical for companies to derive significant business value from the PCB assembly prototyping process and mitigate technical uncertainty risks early on.

Previous

Previous :

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs