Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

The Importance and Forms of PCBA Testing

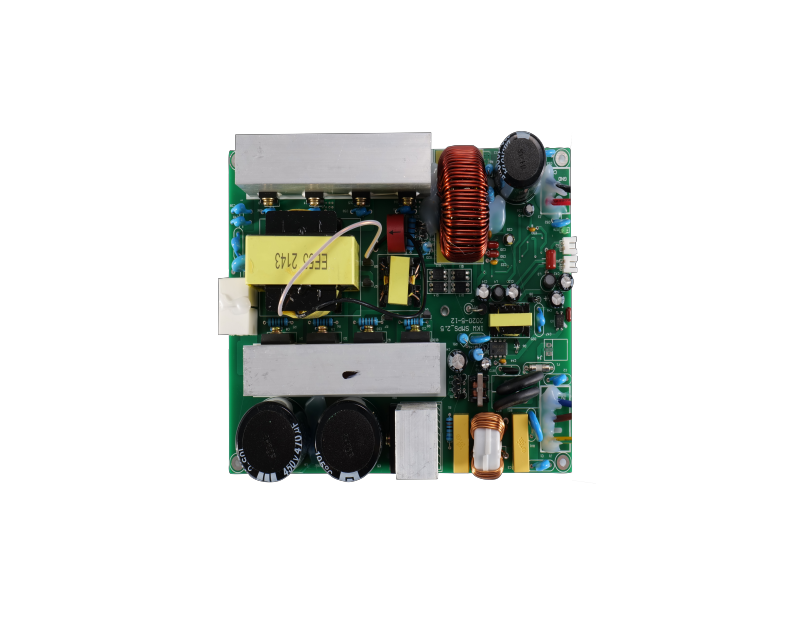

When it comes to PCBs, we are all familiar with them, but do you know what PCBA is? PCBA refers to a finished product assembled from a PCB board through processes such as SMT surface mounting, DIP plug-in, and testing. We can understand it as a finished circuit board. PCBA testing is to test the conductivity performance and input/output values of the PCBA board. Why does PCBA need testing?

When it comes to PCBs, we are all familiar with them, but do you know what PCBA is? PCBA refers to a finished product assembled from a PCB board through processes such as SMT surface mount, DIP plug-in, and testing. We can understand it as a finished circuit board. PCBA testing is to test the conductivity performance and input/output values of the PCBA board. Why does PCBA need testing?

The production and processing technology of PCBA is very complex, including PCB board production, procurement of electronic components, testing, SMT surface mount, DIP plug-in, and many other processes. In the production factory, various problems may occur due to various reasons, so professional testing equipment is needed, such as using a multimeter for testing, to confirm the integrity of the PCBA board design.

The importance of PCBA testing is reflected in the following points

Improve enterprise production capacity: The higher the PCBA testing pass rate, the higher the product pass rate, improving product quality and promoting the improvement of enterprise production capacity.

Improve enterprise economic benefits: Only products that pass the test will be favored by users. In the testing process, errors can be found and adjusted in time, making the product more perfect, then put into the market, favored by customers, and stimulating the development of enterprise economic benefits.

PCBA testing generally adopts the following forms

ICT testing: Tests circuits, current, voltage, amplitude, and noise.

FCT testing: Tests the functions of the PCBA, such as whether the LED light can be turned on after pressing the button, whether it can be restored to factory settings, etc.

Fatigue testing: The sample is operated at a high frequency and for a long time to observe whether any faults occur and to judge the probability of faults, thereby understanding the performance of the PCBA process board.

Extreme environment testing: The PCBA board is placed in harsh extreme environments such as high temperature, low temperature, and drop, and the reliability of the PCBA board is calculated based on the test results.

PCBA testing is an indispensable important link to ensure product delivery quality, determines product performance, controls product quality, reduces after-sales and rework rates, makes customers more at ease, and promotes win-win cooperation between enterprises and customers.

PCBA rework and repair technical conditions and specifications

The basis of PCBA processing rework and repair

PCBA processing rework and repair should be carried out strictly in accordance with the PCB design documents and repair regulations, and rework and repair should have unified process specifications.

The number of times each solder joint is allowed to be reworked

Rework is allowed for defective solder joints, but the number of rework times for each solder joint cannot exceed three times, otherwise it will cause damage to the welding area.

Use of removed components

Removed components must not be reused. If necessary, they must be screened and tested according to the original electrical and process performance of the components before installation.

The number of times each solder pad is allowed to be disassembled and soldered

Each printed solder pad should only be disassembled and soldered once (i.e., only one component is allowed to be replaced). The thickness of the intermetallic compound of a qualified solder joint is 1.5-3.5μm. After remelting, the thickness will increase, and may even reach 50μm, the solder joint becomes brittle, the welding strength decreases, and under vibration conditions, it will bring serious reliability risks. Moreover, remelting IMC requires higher temperatures, otherwise IMC cannot be removed. The copper layer at the via exit is thinner, and the solder pad is easily broken from this position after remelting; the copper layer deforms due to Z-axis thermal expansion, and the solder pad may fall off due to the obstruction of the lead-tin solder joint.

In the case of lead-free, the entire solder pad will be lifted, and due to the moisture between the glass fiber and the epoxy resin, it will cause PCB delamination. After heating, the solder pad is easily warped and separated from the substrate due to multiple welding.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs