Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

What factors should PCBA manufacturers consider when selecting the optimal PCB?

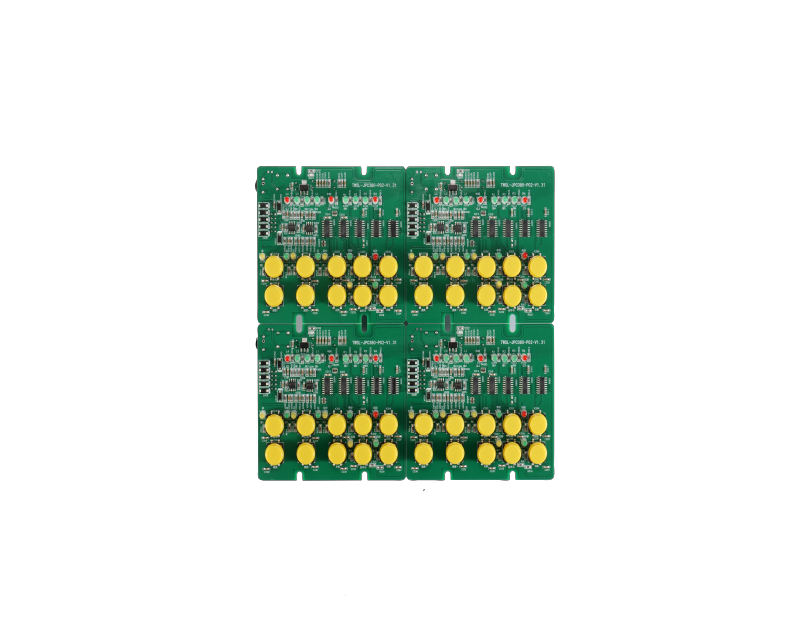

Now you should have a good understanding of what a PCBA is. It is the two parts needed to manufacture the device. Once you have the PCB substrate, you can organize various components on the circuit board, such as transistors, transformers, ICs. This component is the PCBA.

When outsourcing your custom PCB prototypes for PCBA preparation, several factors must be carefully considered.

Printed Circuit Board Manufacturing

When searching for a superior PCB manufacturing company, it's crucial that their primary business is manufacturing printed circuit boards, not just acting as brokers or intermediaries. A company that only brokers orders may not possess the same level of commitment or expertise as one that manufactures the boards, potentially leading to issues with PCB quality or delivery.

No Minimum Order Limit (MOL)

Furthermore, a reputable PCB manufacturer will not restrict the number of PCBs you can order, a practice often referred to as a minimum order limit (MOL). Companies should allow clients to order parts according to their needs. Otherwise, it limits customer flexibility and ultimately leads to dissatisfaction.

Diverse PCB Soldering Techniques

In PCBA (Printed Circuit Board Assembly) manufacturing, the company should be proficient in various PCB soldering techniques, such as Surface Mount Technology (SMT), through-hole, and hand soldering. These methods each have specific applications and advantages, and a superior manufacturer should possess the expertise to select and execute the correct technique for a given project. This expertise is crucial for ensuring the effectiveness and reliability of the assembled board.

Delivery Time

Delivery time, the time from order placement to delivery, is another key consideration when choosing a PCBA manufacturer. The company must guarantee timely delivery of the assembled boards, as delays can disrupt your production schedule or product launch. Beyond timely delivery, the manufacturer should also provide a detailed Design for Manufacturing (DFM) report. This crucial document offers suggestions to enhance design manufacturability, helping you avoid potential manufacturing issues and subsequent costs.

Pricing

Finally, pricing plays a significant role in your selection process. PCBA manufacturer quotes should be competitive, aligned with market rates, and negotiable. Rigid pricing structures may limit your ability to maximize the value of your investment. Discussing and negotiating with the manufacturer to obtain better pricing can help you manage your budget while ensuring you receive a high-quality product.

Wondering where to find a PCBA supplier that meets these requirements? We can fulfill your needs. Our team of expert engineers and workers prepare various PCBs and assemble them with electronic components.

Additionally, our pricing is competitive, and there are no order limits. You can obtain anywhere from 100 to 100,000 fully assembled PCBs. Last but not least, we guarantee on-time delivery, and every component is quality tested and certified.

Conclusion

Now you should have a good understanding of what PCBA is. It is a two-part process of manufacturing the required device. Once you have the PCB substrate, you can organize various components on the board, such as transistors, transformers, ICs. This assembly is the PCBA.

The two techniques for PCBA are SMT and through-hole. You must carefully and correctly install these components. At our company, you are sure to receive accurate and precise PCBAs on time and at a competitive price.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs