Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

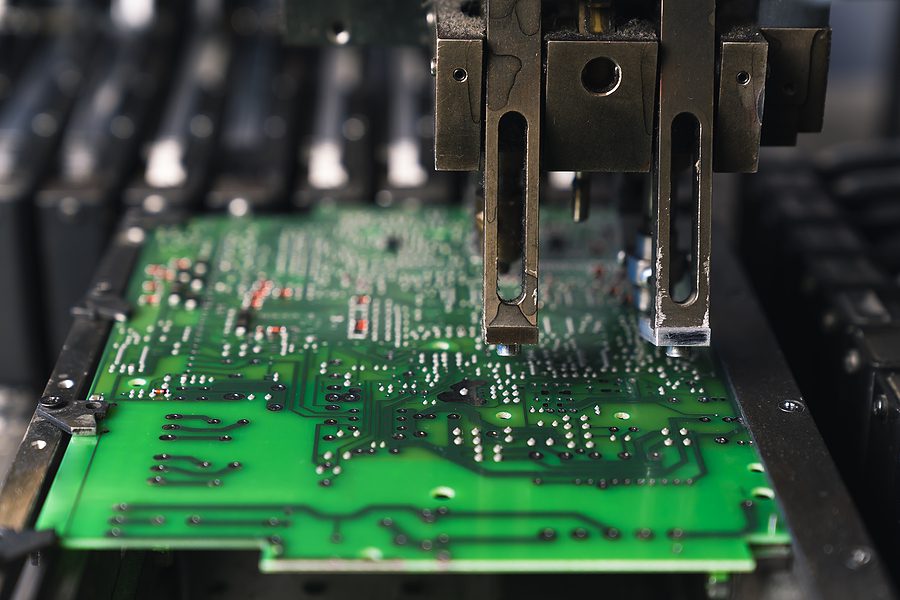

Is it really worthwhile to outsource PCB assembly?

PCB manufacturers are business partners closely related to your success. The right supplier is your partner in every aspect, from PCB design layout to distribution process. A suitable supplier will include an in-house engineering team to assist with redesign. This is a great advantage if you are trying to focus on new products but also need someone to manufacture old products.

More and more manufacturers are realizing the advantages of outsourcing PCBA compared to establishing in-house processes, and for good reason.

If you are considering whether it is worthwhile to outsource your PCB assembly, the answer is a resounding yes. When you consider all the costs, outsourcing PCB assembly to a domestic, experienced turnkey factory can save you time and money. Beyond cost, you will also gain an expert team to help ensure your project's success.

Reduced Investment

Purchasing surface mount and quality inspection machinery is a significant upfront investment, as is the cost of certification for manufacturing professional industry project PCBs. You will also need to hire new employees, so you must also factor in their annual salaries, health insurance, and retirement costs.

With outsourced PCB assembly, you won't have to worry about any of these issues.

Save on Facility Costs

Renting or leasing warehouse space will quickly drain your funds, especially when you need to pay property taxes. By outsourcing, your electronics supplier can hold parts for you internally, so you don't need to find space to store all your inventory. Your PCB manufacturer will bear the financial responsibility until the parts ship out.

The reduction in costs gives you the opportunity to invest funds elsewhere, such as marketing, R&D, or wherever it is needed.

Cost Effectiveness

Establishing infrastructure and operations takes years. Your electronics manufacturing services provider has already done this. Why spend years trying to build your own infrastructure and operations when there's a simpler way?

PCB manufacturing experts already understand inventory management that impacts cost efficiency, such as:

Short part lifecycles

Price fluctuations

Design changes

If you are a startup with limited funds, seeking out an experienced, well-managed board assembly service is far easier than trying to integrate the processes yourself.

Invaluable Expertise

Experts are called experts for a reason. PCB assembly services are their bread and butter, day in and day out. They understand the industry and are already thinking ahead about potential problems you may never have considered, such as:

Delivery times

Design flaws

Conflict materials

Intrinsic safety

Imagine handing the project to a PCB contractor who can identify design issues before the product goes to market, avoiding all potential headaches. The same partner can also help you redesign or refit the board to improve manufacturing efficiency. This happens frequently in outsourced PCB assembly.

Focus on Design

Contracting a company can free you up to focus on the more important aspects of PCB design. With the collective hands and minds of a team freed up, you can focus on other aspects of engineering or business building. Your resources may be better suited to marketing your product or breaking into new markets.

Shorter Lead Times

Your PCB contractor likely maintains long-standing relationships with multiple component manufacturers. The supplier will have a mature supply chain, including component brokers and others who may contribute to shorter lead times.

Assembling circuit boards requires a larger team and larger space than your facility can handle. Without the team and space, it's difficult to get orders to customers on time. However, electronics manufacturers who focus on manufacturing and assembling PCBs can complete orders quickly and efficiently.

Higher Capacity

The benefits of outsourcing PCB assembly include having a larger team and a larger workspace. Furthermore, contractors understand economies of scale. Once order volumes reach 10,000 pieces, you may need to redesign the board to make it more suitable for mass production. A trusted and experienced assembly service can help you achieve this. If you want to assemble large-volume orders yourself, you will need ultra-expensive installation and inspection equipment to meet capacity needs.

After-Sales Service and End-of-Life Management Options

PCB manufacturers are business partners invested in your success. The right supplier is your partner from PCB design layout to distribution processes and everything in between. The right supplier will include an in-house engineering team to assist with redesigns. This is a huge advantage if you are trying to focus on new products but also need someone to manufacture older ones.

The partnership continues after product launch, as a full-service PCB supplier can perform failure analysis.

Conclusion

For a turnkey manufacturing experience, contract PCB manufacturing is the superior solution. To enjoy added benefits such as end-of-life management and design assistance, and for overall peace of mind, ensure your partner is a turnkey domestic contract manufacturer.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs