Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

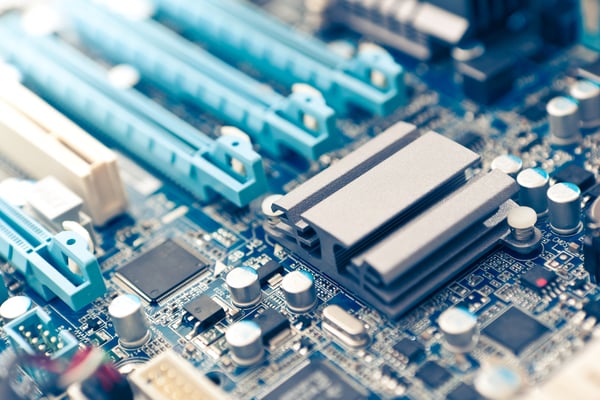

The most suitable PCB substrate type for your circuit board

Collaborating with certain PCB manufacturers can help avoid cross-wiring and reduce your PCB assembly costs and lead times. "Certain" refers to contractors who assist with the design phase as needed. The more design work completed with PCB layout and assembly services, the more likely they are to provide good advice on the type of PCB material you should use.

Typically, the foundation or base of a printed circuit board (PCB) consists of a substrate and a laminate. Different PCB laminate and substrate types determine the performance of the PCB. Therefore, selecting the correct type of PCB material for the intended use is critical for achieving optimal performance:

Functionality

Longevity

Cost-effectiveness

These qualities should be part of any PCB design guideline and are the qualities we will keep in mind as we discuss below.

Different Types of PCB Substrates Mean Different Results

The materials you use for your PCB will affect both short-term and long-term performance, as well as the contractor's ability to manufacture it. Like anything else—you get what you pay for. If you buy inferior materials and they fail when the contractor tries to manufacture the board, you can't blame the contractor.

So what should be used? Commonly used materials in PCB substrates include FR-1 and G-10 to PTFE, Alumina, and Kapton. Laminates are made from CTE, PTFE, CEM and various other compounds.

When high performance is not a necessary characteristic of the PCB, materials such as lightweight polyester may be a good choice. In this case, there are at least two reasons to choose lightweight polyester, as long as it is used in conjunction with Printed Electronics (PE) technology.

Advantages of PE using lightweight polyester include:

Lower Cost - Lightweight polyester produces less waste, requires fewer processing steps, and reduces the need for water treatment and filtration.

Versatility - Flexible printed circuits (FPCs) are available, but to achieve the level of "bendability" that makes them so attractive, the cost is very high. PE using lightweight polyester can maintain flexibility at a much lower price.

However, traditional PCBs remain a good choice for high-performance applications, and the decision of which material to use in the manufacturing process should depend on the type of board required. For example, does the board:

Handle frequencies between 500MHz and 2GHz?

Withstand high power and high temperatures?

Complex and "dense"?

Manage microwave levels and above?

PCB Material Selection Guide PCB Substrate PCB Material Type

Clearly, the cost difference between substrate and laminate materials is significant. But choosing the right material from the start is worthwhile rather than suffering the ignominy of costly PCB failures.

Here are some general recommendations that can serve as a starting point for selecting specific substrate/laminate application materials:

FR-4 is widely used in standard boards. Its Tg is 135˚C. It also has high Tg versions (150-210˚C), making it suitable for high-density applications.

CEM-1, CEM-2, and CEM-3 also perform well in high-density applications. CEM-1 has a Tg of 122˚C, CEM-2 has a Tg of 125˚C, and CEM-3 has a Tg of 125˚C.

For substrates, RF-35 offers a Tg of 130˚C, making it a candidate material for high-density applications.

PFTE is a good choice for high-frequency, microwave, and high-power boards, with a Tg between 160-280˚C.

Polyimide, as a substrate, has a Tg of 250˚C or higher, suitable for high-power, high-frequency, and microwave applications. Polyimide substrates are a good choice for flexible circuits because FR4 substrates are very rigid. In addition to flexibility, polyimide also has high temperature resistance, but is more expensive than FR4.

"Approved Equivalent"

Today, it is wise to work with laminate manufacturers and specify a material or its "approved equivalent." In other words, you provide a specific material to the contract manufacturer, but also allow them to deviate from that material if necessary - with your approval.

The reason for this wording is simple. One board mill might give you a high-quality substitute, while another might give you the cheapest scrap it can find.

Therefore, communicate your wish list as clearly as possible. Years ago, FR4 was a very specific term; now it has become a more generic term. Unless you completely trust the manufacturer, don't leave the choice of PCB material to the manufacturer.

What's Next for Your PCB Design?

Choosing the right substrate and laminate for your PCB application is not easy. When you enter the realm of high-density, high-frequency, or microwave frequencies, a delicate balance needs to be maintained between quality and cost efficiency.

Working with certain PCB manufacturers can avoid crossed wires while helping you reduce PCB assembly costs and lead times. "Certain" refers to contractors who assist with the design phase as needed. The more design work that is completed with PCB layout and assembly services, the more likely it is to provide good advice on the type of PCB material you should use.

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs