Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Matters needing attention in PCBA processing and board separation

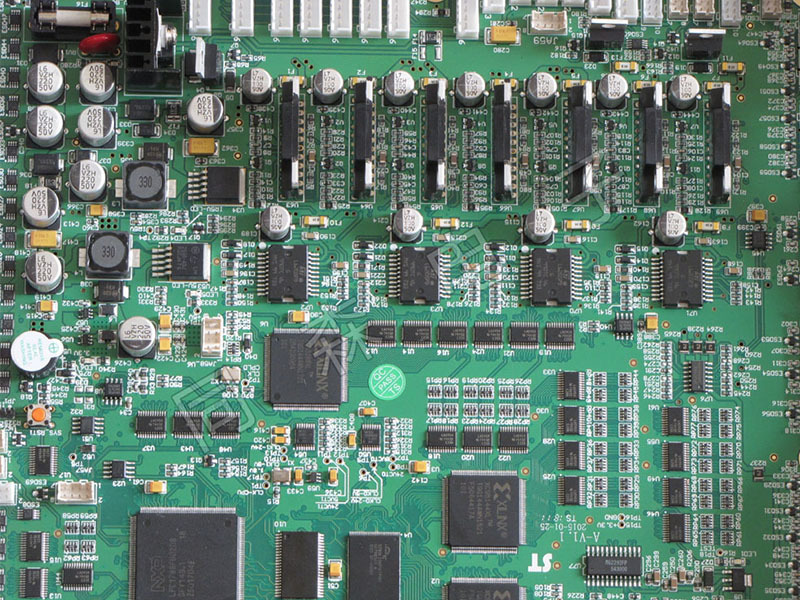

When processing PCBAs, some PCBs are relatively small. To improve production efficiency, we need to make panel arrays. After PCBA processing, the PCBA panel needs to be separated. Therefore, some precautions should be taken during the separation process to prevent damage to intact PCBAs.

When manually separating boards, pay attention to holding the lower edge of the PCBA board with both hands, and try to avoid bending, deformation, damage to the PCBA electrical circuit and components, and solder joints.

Machine separation requirements:

1. Stable support points.

Without support, stress may damage the substrate and solder joints. Twisting the board, or stress generated during separation may cause hidden or obvious defects.

2. Wear protective gear.

Protective measures must be taken before operation. High-frequency eye protection lighting devices need to be installed to protect the safety of operators. It is best to wear safety glasses to protect your eyes.

3. Regularly wipe the machine spindle and tools with alcohol to remove PCB dust generated during the separation process and maintain the normal operation of the separation machine.

4. After a certain number of uses, lubricate the slide rods and bearings of the separation machine and check if the screws are loose.

5. During machine operation, the workbench should be kept clean. It is best not to place other items to avoid damaging the tools and items. Although there are electric eyes for maintenance, a certain safety distance should be maintained between the fingers and the tools during operation.

Generally speaking, when separating PCBA boards, the efficiency of machine separation is higher than that of manual separation. The damage rate is low. However, when using machine separation, the process should be strictly followed to reduce human error.

Next :

RECOMMENDED NEWS

High-end Custom Services: SMT Chip Processing Meets Diverse Industry Needs