Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Main business scope

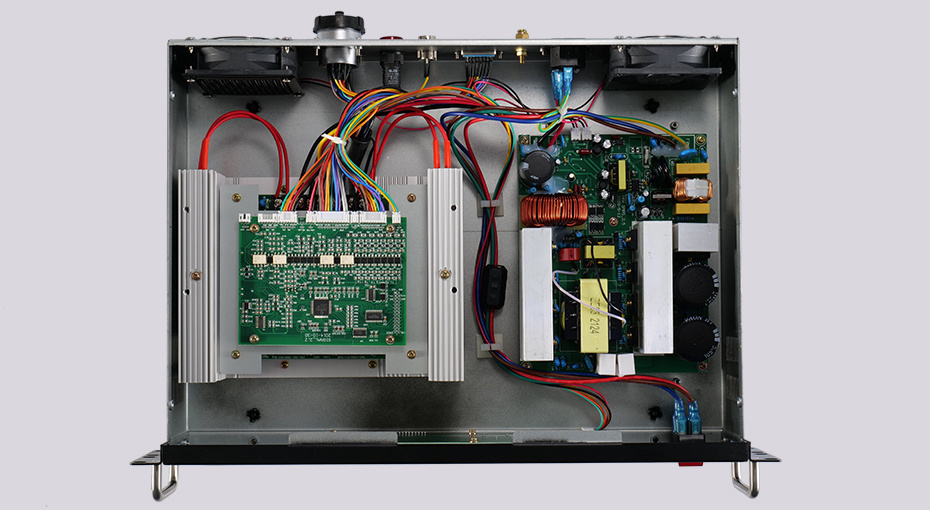

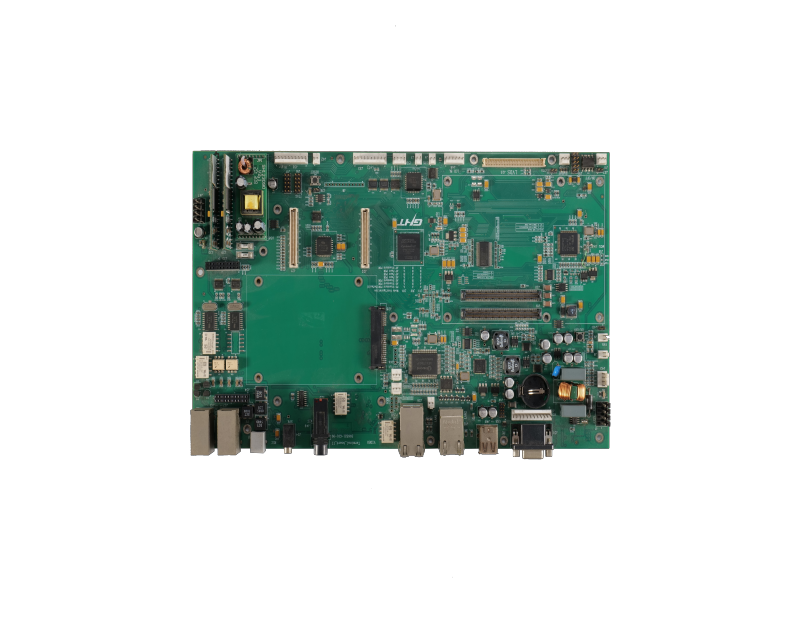

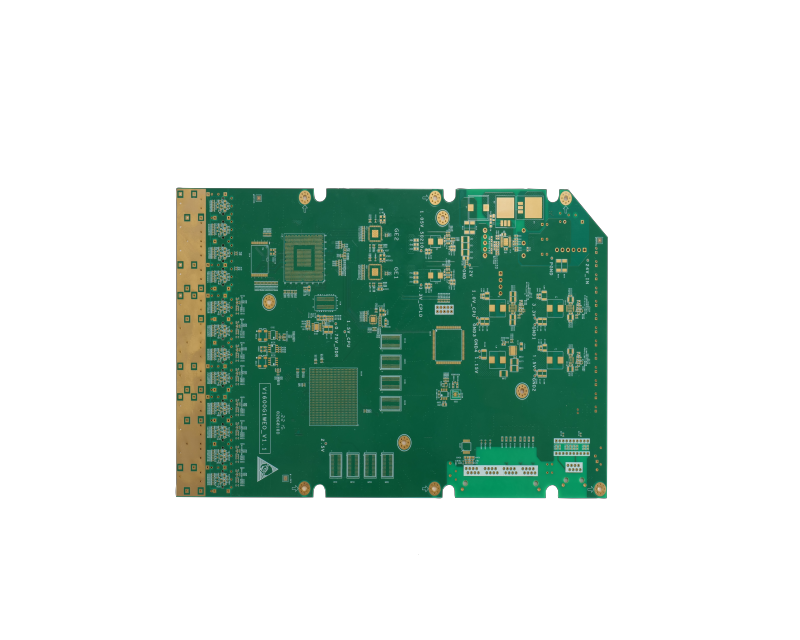

A full range of services from PCB production, component procurement to SMT patch, DIP plug-in processing

DetailsUndertake SMT patch and DIP plug-in processing, including sample trial production and batch product...

DetailsFinished product assembly test

Standard assembly cable, SOP standard operation, all kinds of testing instruments are complete, equipped w...

DetailsSOLUTION

OURADVANTAGE

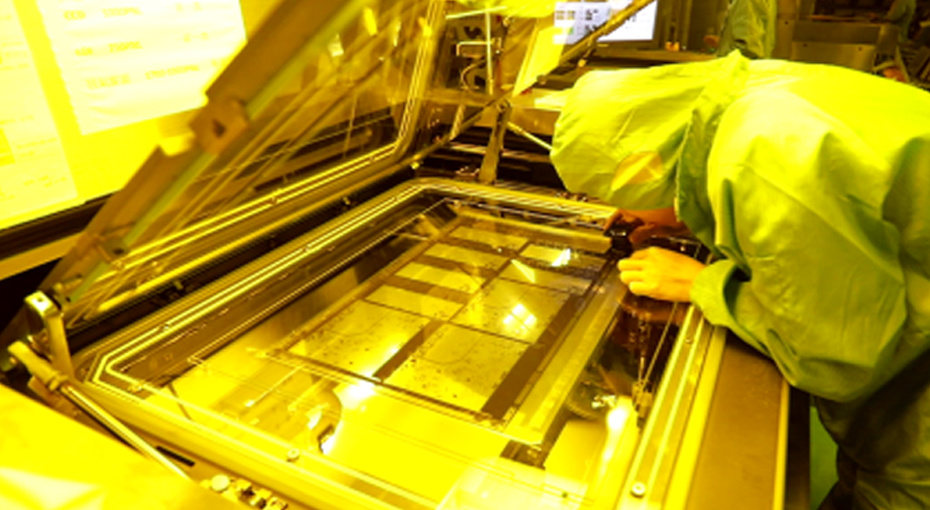

High-end complete equipment

Configuration: new FujiNXT-3 high speed mounter, Samsung 471,48,482 medium speed machine, GKG full automatic printing machine, online

Intelligent management

The company introduced and comprehensively introduced MES system management software, put an end to the error of human factors, effectively solved the

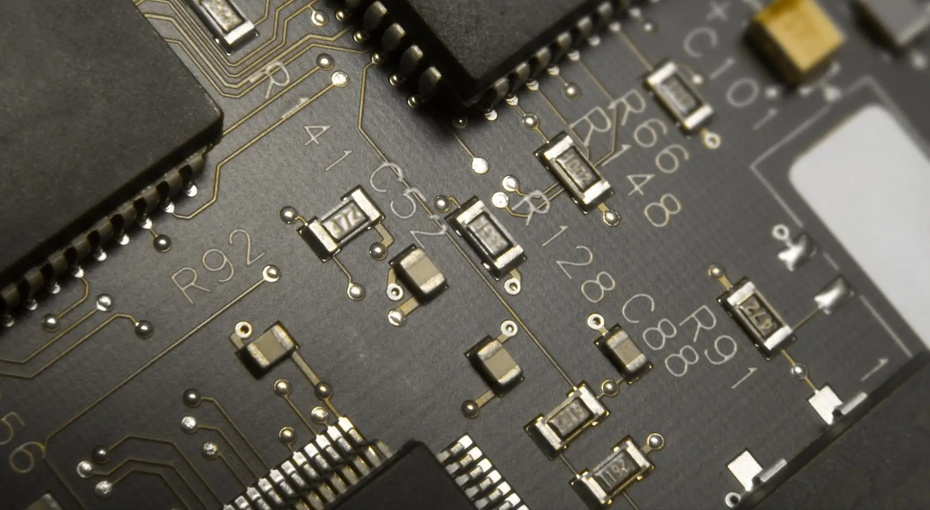

High precision and high quality

It can mount 0.2MM-BGA chips, 01005 precision small devices and various types of FPC soft boards. The company has a complete quality system

Strong purchasing capability

The company has a senior component supply chain team, and has more than 100,000 kinds of common materials inventory, the company has

Stable and experienced team

80% of the company's employees have been working in the industry for more than 6 years, and the main positions for more than 10 years.

One-to-one caring service

We are equipped with professional knowledge and experienced customer service team, the whole process arranged one-on-one service,

BUSINESS PROMOTION

ABOUT TONGSENG

Guangzhou Tongsen Electronic Technology Co., Ltd. (Guangzhou Xinpin Electronics Manufacturing Co., Ltd.) is a high-tech enterprise established in 2008 with a paid-in registered capital of 10 million RMB.It is located in Guangzhou Science City, the largest high-tech zone in Guangzhou, with a plant area of nearly 5,000 square meters and nearly 200 employees. It is equipped with six new Fuji NXT-3SMT SMT production lines, three DIP plug-in production lines, two assembly lines and high temperature aging room. We have also been certified by IATF16949, ISO9001, UL, CCC, SGS, ROSH and other related certifications. The business areas cover industrial control, military industry, automotive electronics, electric power, medical treatment, Internet of Things, robotics, communication modules, security protection, cloud computing, instrumentation, etc. We are working with more than 200 long-term and stable partners, including Chinese Academy of Sciences, Amphenol and other well-known domestic and foreign companies, and more than ten A-share listed companies such as Infore Environment, Royal Silver, Baiyun Electric, and Higer Communications.

More

More

Company Environment

Born great

Plant area

Number Of Workers

SMT processing capacity

BLOG

Common Problem

Q

How to detect counterfeit electronic components during PCBA processing?

A

Q

Introduction to SMT processing and production process

A

Q

How to determine if a PCBA processing plant is reliable?

A

2. Company environment: The factory's hygiene can directly reflect the factory's production quality. The factory's production environment and production results are not directly related, but the better the production environment, the higher the factory's requirements for the process. Only those who pay attention to the details will be more focused on serving customers and doing a good job on customers' products.

3. Product quotation: The price of SMT patch prototyping is relatively transparent in the industry; some are too high, and some are very low, all kinds of messy things. Tongsen Electronic chooses to purchase original parts from formal channels and strictly controls product quality. Although this increases processing costs, it can guarantee product quality. However, some PCBA processing plants may choose to cut corners and use fake raw materials to reduce prices, resulting in unstable quality. We should choose the most cost-effective manufacturer based on our own situation and not choose small workshops without quality assurance to save money. 4. Service: As the brain of intelligent products, PCBA circuit boards are not just manufactured. As a qualified supplier, pre-sales and after-sales service should also be equally valued. A trustworthy factory has good service awareness, can solve many unnecessary problems for customers during the manufacturing process, provide reliable after-sales support, and respond quickly to customers, thus ensuring the smooth progress of production. We can choose a more suitable supplier by understanding the company's corporate culture and the factory's attitude towards customers.

PCB Board Manufacturing Process Revealed: Preliminary Steps for SMT Chip Mounting

PCB Board Manufacturing Process Revealed: Preliminary Steps for SMT Chip Mounting